18

EN

Operating and assembly instructions HRD FU-ATEX

www.elektror.com

9016330 01.20/08

unapproved replacement of components constitutes non-

designated use and renders the warranty void. The resul-

tant risk shall be borne solely by the customer or owner.

Note!

Reliable protection against incursion by foreign

matter, rust, airborne rust and other iron oxides is

provided.

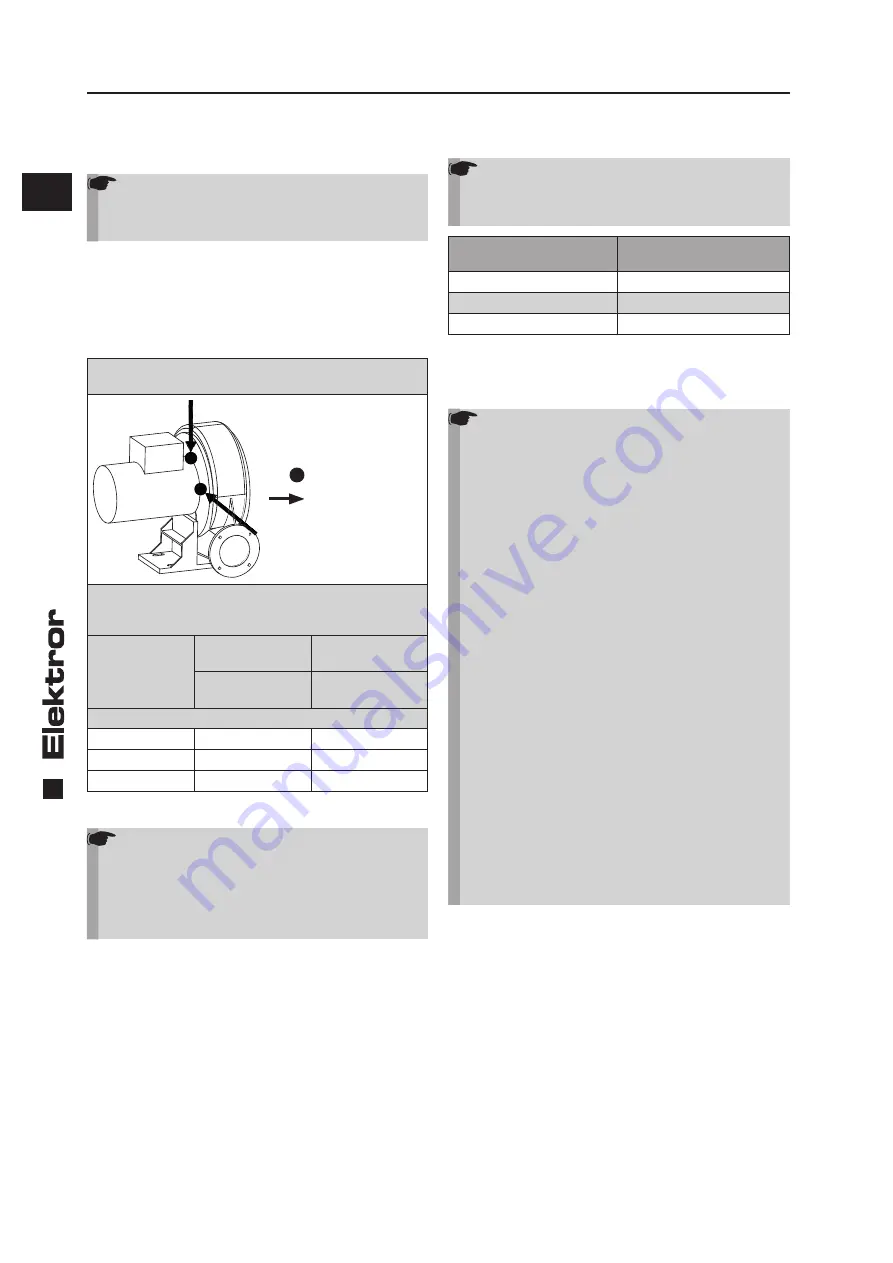

3.2 Installation and assembly

• During set-up, installation and subsequent operation,

never expose the equipment to vibratory or impact loads.

• Cover the open intake and/or a discharge side connection

with wire guards compliant with DIN EN ISO 13857.

Measurement at the

fl

ange bearing shield, preferably

near the bearing

= Measuring point

= Measuring

direction

Maximum permissible vibration speed

(Limit values according to ISO 14694:2003 (E),

category BV-3)

Rigidly mounted

[mm/s]

Flexibly mounted

[mm/s]

E

ff

ective value

[r.m.s.]

E

ff

ective value

[r.m.s.]

At installation

Start-up

4,5

6,3

Alarm

7,1

11,8

Shut-down

9,0

12,5

3.3 Electrical connection

Note!

The work described in this section may only be

performed by a quali

fi

ed electrician. The dimen-

sioning and selection of connecting lines, includ-

ing the connection of the motor, must be made

according to the circuit diagram in the junction

box and the relevant local regulations.

• Design of the electrical installations in accordance

with EN 60079-14.

• Complete equipotential bonding must be achieved; i.e.

su

ffi

cient and proper earthing of all electrically conducting

parts.

• Check that the mains voltage matches the speci

fi

cation

on the nameplate.

• The drive motors used are exclusively explosion-protected

three-phase current motors.

• The safety earth terminal can be found in the terminal box.

• The additional content from the motor and frequency con-

verter manufacturer must be observed and can be ob-

tained from the supplier documentation.

3.3.1 Special features when operating ATEX blowers at

the frequency converter

Note!

Only motors with pressure-proof encapsulation

must be operated at the frequency converter,

marked Ex db eb II2GD T4 135 °C!

Maximum frequency (see

rating plate)

Minimum frequency

50 Hz

5 Hz

60 Hz

5 Hz

> 60 Hz

35 Hz

A direct evaluation of the PTC-resistor sensor by the fre-

quency converter is not usually permissible in ATEX applica-

tions (in this regard, please refer to the speci

fi

cations of the

converter manufacturer!).

Note!

For operation of the drive motor with a frequency

converter, the following points should also be

noted:

• Only motors marked Ex db eb motor „frequency

converter compatible“ must be used at the fre-

quency converter.

• Unless expressly stated by the motor manufac-

turer, the converter supply voltage must not ex-

ceed 400 V and the cable length must not exceed

20 m. For longer cable lengths, higher supply

voltages and/or special EMC requirements, suit-

able additional measures may be necessary. In

this case, please contact the converter supplier. If

additional

fi

lter components are required, ensure

that su

ffi

cient space is reserved in the control

cabinet.

• The connection cables must be kept short and

laid without interim terminal points and without

connectors.

• Connect the motor and PTC evaluation cable be-

tween the motor and frequency converter output

with shielded cables.

• Connect the shielding braid of all cables con-

sistently and on both sides, i.e. to the frequency

converter, motor and control cabinet, to establish

a low impedance electrical connection with the

protector conductive system. A suitable EMC

cable gland must be used on the motor side to

establish a low impedance contact with the entire

cable shielding.

3.3.2 Special features of drive motors for frequency

converter operation:

• Depending on the input voltage of the converter, the motor

can operate with a delta or star-point connection. The

speci

fi

cations on the motor nameplate are de

fi

nitive.

• Please refer to the information on EMC-compliant instal-

lation and assembly of the frequency converter, in the

supplier documentation.

• Tripping relays that meet the criteria set out in Directive

IEC 61508 are suitable and able to switch to a fail-safe

safety position in the case of faults.

• Connect the output contact of the triggering device to an

appropriate release input on the frequency converter or

take another appropriate measure, ensuring that the

switch-o

ff

of the fan meets the safety requirements and it

can only be reset manually.