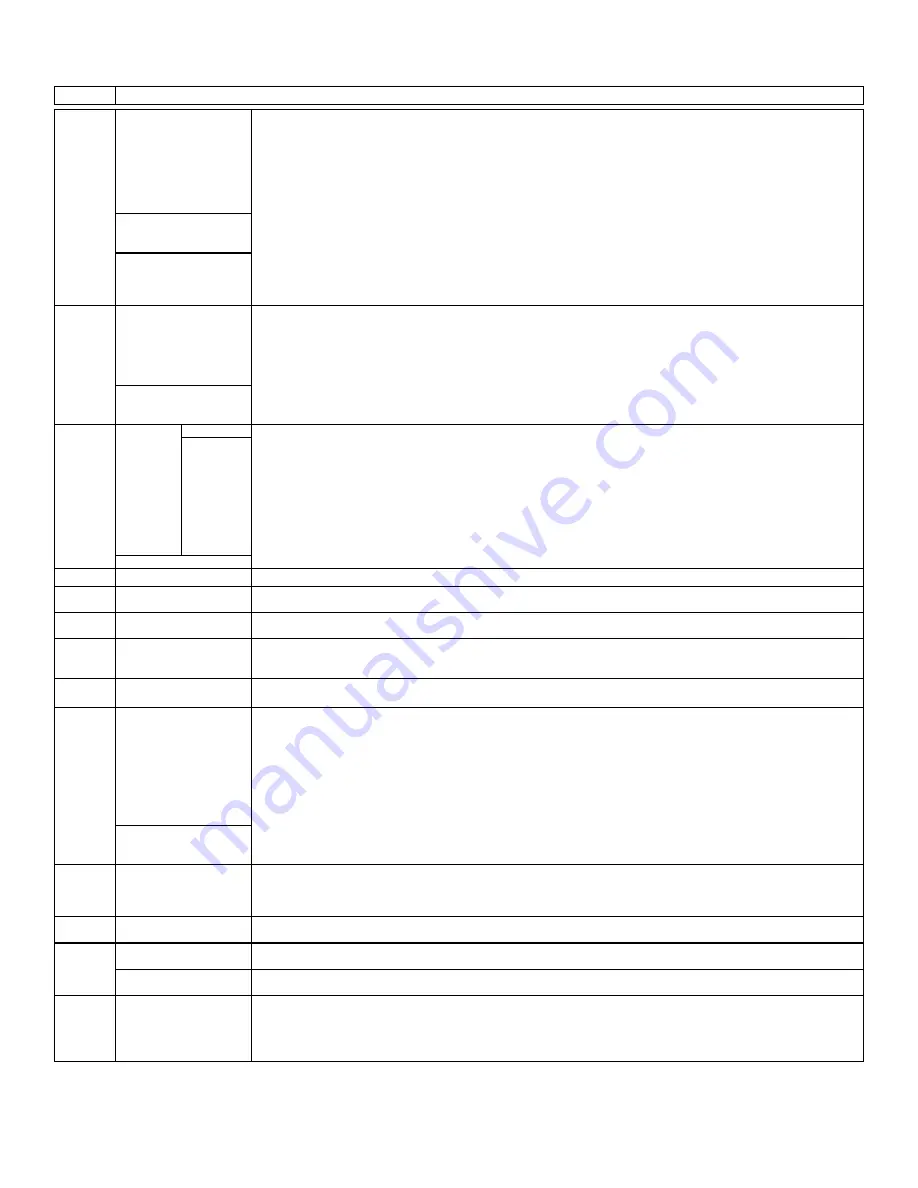

List of Possible Error Causes

Code

Possible error causes

Water tap is closed or faulty

No water pressure, pressure too low or changing

Screen in front of inlet valve clogged

Flow governor at inlet valve faulty

Inlet valve faulty

Inlet valve deenergized (faulty wiring or no activation by electronics)

Inlet hose bent

Softener system clogged (by filling detergent into salt compartment, for instance)

Upright installation without upright assembly kit

Connection height of the discharge hose is lower than 30cm above appliance base

Connection w/o siphon or air chamber

Pressure controller faulty

Pressure controller hose obstructed, bent or leaking

Pressure controller wiring is faulty

Screens in the appliance clogged (also check spray arm nozzles for clogging)

Fault with discharge pump

Discharge pump deenergized (faulty wiring or no activation by electronics)

Obstruction/blocking (filters in the appliance, discharge opening in discharge trough, discharge pump, discharge hose, siphon, cover plug at

siphon connection not removed during first commissioning)

Discharge hose bent or connection height above 100cm

Ball valve in discharge trough glued / blocked (discharge pump does not aerate)

Pressure controller faulty

Pressure controller hose obstructed or bent

Insulation fault with heating element

Leakage

Leakage at recipient, discharge trough, hose system (e.g., Y-type hose), regeneration dosage etc.

Inlet valve faulty (does not close)

Water inlet too high (faulty flow governor at inlet valve)

Connecting hose regenerating dosing to discharge trough blocked

Water inlet channels in regeneration dosing unit blocked

Screens in the appliance clogged (also check spray arm nozzles for clogging)

Pressure controller faulty

Pressure controller hose obstructed, bent or leaking

Pressure controller wiring is faulty

Foam production in the appliance (splashed rinsing liquid / leaking dosing unit or con-compatible detergent / rinsing agent used)

Base trough is dry

Inlet valve or wiring electrically interrupted

i50

Motor triac short-circuit

Faulty electronics

Heating element faulty

Heating element deenergized (faulty wiring or no activation by electronics)

Thermal sensor defect

Wiring faulty (e.g. short-circuit or interruption)

Mains filter defect

Faulty electronics

EMC problem

i90

Check sum error model

programmation

Faulty electronics

Blocking by dishes or cutlery basket

Nozzles clogged (drive nozzles at spray arm extremities)

Spray arm leaking (welding seam)

Spray arm bearing blocked (dirt, foreign bodies)

Screens in the appliance clogged

Bellows at connecting pipe not sealed at recipient rear wall (bellows not contacting/glued together)

Circulating pump does not reach full power (nominal speed is not reached due to winding influence)

Too little water in appliance - for possible causes see Error codes i10 and iF0

Foam production in the appliance (splashed rinsing liquid / leaking dosing unit or con-compatible detergent / rinsing agent used)

No magnet in spray arm

Spray arm detection sensor faulty

Wiring faulty

turbidity sensor defect

Wiring faulty

turbidity sensor dirty

Foam production in the appliance (splashed rinsing liquid / leaking dosing unit or con-compatible detergent / rinsing agent used)

Faulty electronics

Wiring faulty

Circulating pump / capacitor defect

Circulating pump deenergized (faulty wiring or no activation by electronics)

Tachometer generator defect

Wiring faulty

Problem with water inlet in general - see Error code i10, pipette effect in particular (also look for an error memory entry i10)

Problem by incomplete pumping in previous program cycle (remaining water) - see Error code i20 (also look for an error memory entry i20)

Improper loading, e.g. big item (pot, bowl is reversed and fills with water)

Foam production in the appliance (splashed rinsing liquid / leaking dosing unit or con-compatible detergent / rinsing agent used)

ic0

id0

iF0

communication faulty

Circulation pump no function

No tacho signal

recognized

Time limit during filling

exceeded

iA0

Upper spray arm does not

rotate

No spray arm detection

turbidity signal faulty

ib0

i60

i70

i80

No rise in temperature

NTC signal faulty

Check sum error EEPROM

Water is not pumped off

Water level inside appliance is

not detected

i20

Overflow

Water remains

in base trough

i30

i10

No or not enough water let in

Machine runs dry (Siphon

effect)

Water level inside appliance is

not detected