01/10/2008

HI321

TABLE OF CONTENTS

PAGE

INTRODUCTION

1

INSTALLATION

REQUIREMENTS

1

MECHANICAL

INSTALLATION

2

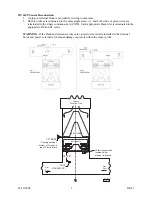

WF

Furnace

Interface

2

EM-WU*****

Upflow

Application

2

EM-WU*****/EM-WD***** Horizontal Application

2

EM-WD*****

Downflow

Application

3

WIRING INSTALLATION

4

High Voltage

4

Low Voltage

4

Outdoor

Sensor

(OT)

4

Supply

Sensor

(ST)

4

WF-LGR4 & WF II Wiring & Setup

6

Chip Code:

HPDH

8

HPDF

9

HPEL

10

OPERATION

INDICATORS

12

Furnace

Interface

Module

12

WarmFlo

II

Controller

12

HANDHELD

ANALYZER/LAPTOP

SOFTWARE

14

SPECIAL

APPLICATION/INSTALLATION

15

For Various Heat Pump, Multi-Speed, Multi-Stage Furnaces, Blower Options, Oil Furnace, etc.

OPTIONAL

ACCESSORIES

16

TROUBLESHOOTING 16

Drawings

Included:

HH340

HD320,

HH339

pg

1

Содержание WARMFLO II

Страница 28: ......