Trispace AR Floor Standing Shell and TubeBoiler

20 L360

©

MHS Boilers 06/09/2013

29 MAINTENANCE

Periodical maintenance is essential for the safety, efficiency and long life of the equipment.

It is also required by law and must be carried out by professionally qualified personnel.

Before carrying out any work, you are advised to perform a combustion analysis to ascertain the operating

conditions and obtain any other useful information.

After performing the combustion analysis and before any other operation:

- disconnect the electricity supply by switching off the master switch;

- close the fuel on-off taps.

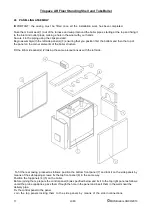

30 OPENING AND ADJUSTMENT OF THE DOOR

The door can be opened from both sides.

The opening is normally from left to right.

To open the door, remove the fixing nuts from the left.

Lifting equipment must be used to change the door opening direction.

Proceed as follows:

- hook the door to the lifting device from the two holes provided at the top;

- remove the four tightening nuts;

- slide the door out;

- unscrew the two locknuts remaining on the tie rods and screw them onto the tie rods on

the other side;

- refit the door ensuring correct location of the locknut seats into the door bushes;

- tighten the four fixing nuts.

To adjust the tightening:

- tighten the adjustment locknuts ensuring that they do not protrude from the door bush seat;

- tighten the fixing nuts adopting a cross sequence. Tighten only as far as required to ensure a uniform

airtight closure.

- screw the adjustment locknuts in until locked.

Usually, at each maintenance operation, the door adjustment should be inspected.