DK50

08/2014

- 7 -

SM-DK50-EN-1-08-2014-MD

PE

N

U

N

X1

U

1

FU

YV1

EV1

C

B1

X2

2

3

4

1/N/PE ~ 230 V 50..60 Hz

ST

40°C

p >

150°C

M

PE

2

1

3

Z2

U2

SP

Z1

U1

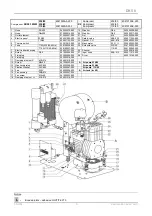

DK50 Z, DK50-10Z, DK50 S, DK50-10S

PE

N

U

YV1

EV1

B1

C

N

U

X1

1

FU

X2

2

3

4

C

B2

150°C

ST

40°C

p >

PE

2

1

3

Z2

U2

SP

Z1

U1

M

DK50 Z, DK50-10Z, DK50 S, DK50-10S

ELECTRIC OBJECT OF 1st CAT.

B TYPE

ELECTRIC OBJECT OF 1st CAT.

B TYPE

1/N/PE ~ 110 V 60 Hz

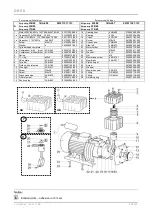

DK50-10Z/M, DK50-10S/M

N

PE

U

EV1

C

EV2

YV1

B1

N

U

1

X1

2

FU

1/N/PE ~ 230 V 50..60 Hz

SP

40°C

p >

ST

3

4

X2

2

PE

3

1

M

Z1

Z2

U2

U1

150°C

1/N/PE ~ 115 V 60 Hz

C

N

PE

U

EV1

EV2

YV1

B1

B2

C

FU

X1

N

U

1

2

3

4

X2

2

PE

3

1

SP

40°C

p >

ST

M

Z1

Z2

U2

U1

150°C

DK50-10Z/M, DK50-10S/M

ELECTRIC OBJECT OF 1st CAT.

B TYPE

ELECTRIC OBJECT OF 1st CAT.

B TYPE

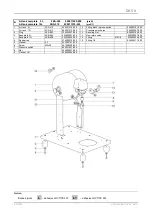

Dental compressor with base DK50 Z, DK50-10 Z

(Fig.4)

After removing all packaging material, place the product on the floor and remove stabilization parts X and Y

(Detail A). Direct the output pressure hose, drain hose and power cord out the back of the compressor.

Dental compressor with base DK50-10 Z/M

(Fig.2, Fig.4)

After removing all packaging material, place the product on the floor and remove stabilization parts X and Y

(Detail A). Direct the output pressure hose and power cord out the back of the compressor. Install the

magnetic holder (16) with a vessel (20) to capture condensate from the dryer on the side of the cooler.

Dental compressor in box DK50 S, DK50-10 S

(Fig.4)

After removing all packaging material, place the product on the floor and remove stabilization parts X and Y

(Detail A). Direct the output pressure hose, drain hose and power cord out the back of the compressor. Slide

the box over the compressor so that the front face of the box matches the front part of the compressor and

the box is fully seated. Make sure that the pressure hose, drain hose and electric cord come out via the

opening at the back of the box. Position the drain hose with its valve in the holder at the rear of the box.

Dental compressor in box

DK50-10 S/M

(Fig.4)

After removing all packaging material, place the product on the floor and remove stabilization parts X and Y

(Detail A). Direct the output pressure hose, drain hose and power cord out the back of the compressor. Fit

the housing over the top of the compressor, connect the flexible shaft to the control button, fasten with the

screw and put the lid on the cabinet housing (see picture). Make sure that the pressure hose, drain hose and

electric cord come out via the opening at the back of the box. Connect the condensate drain hose to the

vessel (20). The magnetic holder (16) with a vessel (20), for entrapping condensate from a dryer may be

fixed at the sides of housing or from the front on its doors. When fixing the holder with a vessel at the

housing side it is necessary to consider a space of at least 11 cm between the housing and furniture.

Distance smaller than the specified one may cause problem with handling of the vessel.

The vessel must always be installed so that the lower section is near the floor; any

other installation may damage the dryer!

5. WIRING DIAGRAMS

M Motor of compressor

EV1 Fan of compressor

EV2 Fan of dryer

YV1 Solenoid valve

of compressor

FU

Fuses 230/50-60 (T10A)

110/50-60 (T16A)

ST Thermo switch

CB1,CB2 Capacitor

SP Pressure switch

X1,X2

Terminal