Caution:

앬

Make sure that the chain tension is always

correctly adjusted.

앬

Only use a chainsaw if it is in perfect working

order.

앬

Only work with a saw chain that has been

properly sharpened in accordance with the

instructions.

앬

Never operate the saw above shoulder height.

앬

Never cut with the upper edge or the tip of the

sword.

앬

Always hold the chainsaw firmly with both hands.

앬

Whenever possible, use the claw stop as a

leverage point.

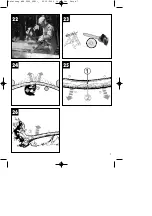

Cutting wood which is under tension

Special care is required when cutting wood which is

under tension. Wood which is under tension from

which it is released by cutting may in some cases

react completely unpredictably and uncontrollably. In

the worst case this could result in extremely severe or

even fatal injuries (Fig. 24-26).

This type of work must only be performed by persons

who have been specially trained.

7. Technical data

Mains voltage:

230 V ~ 50 Hz

Power rating:

2000 W

Cutter rail length:

40 cm

Cutting length, max.:

375 mm

Cutting speed at rated rpm:

13.5 m/s

Oil tank capacity:

300 ml

Weight with cutter rail and chain:

5.6 kg

Protection class:

II

Guaranteed sound power level under load 107 dB(A)

Sound pressure level under load

87 dB(A)

Acceleration:

(calculated according to EN 50144)

Handle under load

4.52 m/s

2

8. Maintenance

8.1 Replacing the saw chain and cutter rail

The cutter rail needs to be replaced if

앬

the guide groove of the cutter rail is worn;

앬

the nose sprocket in the cutter rail is damaged or

worn.

Proceed as described in the section “Assembly of the

cutter rail and the saw chain”.

8.2 Checking the automatic chain lubrication

You should check the operation of the automatic

chain lubrication system on a regular basis in order to

guard against overheating and the associated

damage to the cutter rail and the saw chain. To do

this, point the tip of the cutter rail towards a smooth

surface (board, section of a cut tree) and allow the

chainsaw to run.

If an increasing oil trace becomes evident during this

process then the automatic chain lubrication system

is working properly. If no clear oil trace is evident then

please refer to the corresponding instructions in

“Troubleshooting”. If the information contained there

still fails to remedy the situation then please contact

our service department or another similarly qualified

workshop.

Caution:

Do not actually touch the surface with the

tip of the cutter rail when performing this test. Keep a

safe distance (approx. 20 cm).

8.3 Sharpening the saw chain

Effective working with the chainsaw is only possible if

the saw chain is in good condition and sharp. This

also reduces the risk of kickback.

The saw chain can be re-sharpened by any dealer.

Do not attempt to sharpen the saw chain yourself

unless you have the necessary special tools and

experience.

9. Cleaning and storing

앬

Regularly clean the clamping mechanism by

blowing it out with compressed air or cleaning it

with a brush. Do not use tools for cleaning.

앬

Keep the handles free of grease so that you can

maintain a firm grip.

앬

Clean the device as required with a damp cloth

and, if necessary, mild washing up liquid.

앬

If the chainsaw is not to be used for an extended

period of time then you should remove the chain

oil from the tank. Briefly immerse the saw chain

and the cutter rail in an oil bath and then wrap

them in oil paper.

Caution:

앬

Always disconnect the mains plug before

cleaning the chainsaw.

앬

Never immerse the unit in water or other liquids in

order to clean it.

앬

Store the chainsaw in a safe and dry place out of

the reach of children.

GB

21

Anleitung NKS 2000_SPK1:_ 05.12.2006 16:13 Uhr Seite 21

Содержание 45.002.10

Страница 4: ...4 6 4 5 8 9 7 B A Anleitung NKS 2000_SPK1 _ 05 12 2006 16 12 Uhr Seite 4...

Страница 5: ...5 12 10 11 14 15 13 A B Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 5...

Страница 7: ...7 24 22 23 26 25 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 7...

Страница 86: ...8 2 20 8 3 9 10 11 www isc gmbh info RUS 86 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 86...

Страница 87: ...RUS 87 12 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 87...

Страница 102: ...102 T 1 2 3 2 4 Anleitung NKS 2000_SPK1 _ 05 12 2006 16 13 Uhr Seite 102...