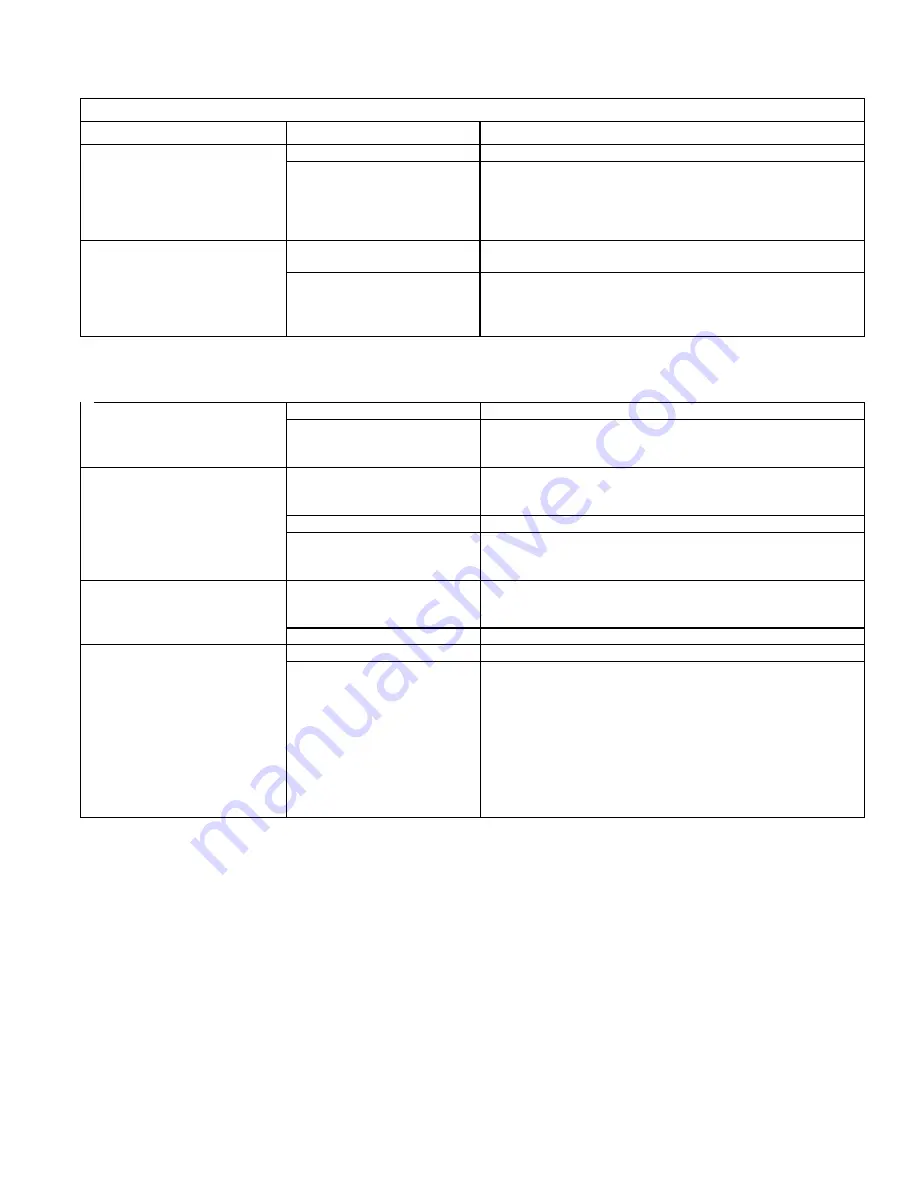

Table C-3: Oil Primary Control Troubleshooting

continued from previous page

Procedure Status

Corrective

Action

Indicator light turns off.

Eliminate external light source or permanently shield cad cell.

4

. Shield cad cell from external

light.

Indicator light stays on.

Replace cad cell with new cad cell and recheck.

If indicator light does not turn off, remove cad cell lead wires

from oil primary control and recheck.

If indicator light turns off, replace cad cell bracket assembly.

If indicator light does not turn off, replace controller.

Burner starts.

Trouble in thermostat or limit circuit. Check thermostat or limit

wiring connections.

5

. Jumper thermostat (T -T)

terminals on oil primary control

IMPORTANT

First remove one thermostat

lead wire.

Burner does not start.

Disconnect the line voltage power and open line switch.

Check all wiring connections.

Tighten any loose connections and recheck.

If burner does not start, replace oil primary control

Condition: Burner starts then locks out on safety with indicator light flashing at 1 Hz rate (½ second on, ½ second

off)

Indicator light stops flashing.

Go to Step 7.

6

. Reset oil primary control by

pushing in and releasing red

reset button.

Indicator light continues to

flash at 1 Hz rate.

Verify that the control is not in restricted mode. (See notes at

end of this table.). If not in restricted mode, replace oil

primary control

Ignition is off

Spark igniter could be defective. Check for line voltage at

igniter terminals. If line voltage is present, replace oil primary

control.

Ignition is on.

Go to Step 8.

7

. Listen for spark after burner

turns on (after 2 second delay).

Ignition is on but no oil is

being sprayed into the

combustion chamber.

Wait for “Valve ON” delay to complete. Check oil supply, and

oil line valve. Check for filter blockage or seized oil pump.

Indicator light is on until the

control locks out and starts

flashing during lockout.

Replace oil primary control

8

. Check indicator light after

flame is established, but before

oil primary control locks out.

Indicator light stays off.

Go to step 9.

Burner locks out.

Go to step 10.

9

. Check cad cell sighting for

view of flame.

Disconnect line voltage power

and open line switch.

Unplug cad cell and clean cad

cell face with soft clothe. Check

sighting for clear view of flame.

Replace cad cell in socket.

Reconnect line voltage power

and close line switch.

Start burner.

Burner keeps running.

System is OK.

30173 Rev B 4/29/2008

25

Содержание HML-C

Страница 33: ...30173 Rev B 4 29 2008 33...

Страница 34: ...30173 Rev B 4 29 2008 34...

Страница 35: ...30173 Rev B 4 29 2008 35...