0

RINSE SPEED CONTROL P.C. BOARD

6.4 Sonalert

®

Volume adjustment

1. Turn all alarm delay switches off.

2. Put the unit into a feed mode by temporarily turning on

additional titration switches and disrupting detergent feed

by holding open the Geosystem Detergent Dispenser

lid.

3. when the Sonalert

®

is activated, set the volume using

the identified potentiometer - clockwise to increase the

volume,

refer to Figure 6-1.

The Sonalert

®

volume should be loud enough to be heard

over the normal noise levels in the dish room , and yet not

too loud that it may disturb customers in the dining room.

6.5 Sonalert

®

alarm Delay

1. Set the alarm delay by using the 10 position dip switch,

refer to Figure 6-1.

SWITCH ON 1 2 3 4 5 6 7 8

9

10

SeCONDS

1 2 4 8 16 32 64 128 256 512

eXAMPLe: For a 2.5 minute (150 second) delay, turn on

switches #8, #5, #3 and #2.

NOTE: On Door Type Machines, the delay should be

approximately 30-35 seconds to allow it to be activated

before the wash cycle is complete.

NOTE: On Conveyer Machines, (unless equipped with

a D-ENERGIZER or other time-out device) the delay

should be a minimum of 2 minutes.

6.6 rinse Speed control

This is the normal mode of operation as a dishmachine

rinse injector. Thru the pressure switch, the pump is ac-

tivated whenever the final rinse is “on”. By adjusting the

speed control, the injection rate of the rinse additive can be

controlled throughout the entire rinse cycle,

refer to Figure

6-2.

Injection rate can also be adjusted by use of alternate

sized squeeze tubes:

INJECTION RATES

PUMP SPEED

Tube Size

3 RPM (minimum)

36 RPM (maxi

-

mum)

1/8 cc/rev

3/8 ml (.0125 oz.)

4.5 ml (.15 oz.)

1/4 cc/rev

3/4 ml (.025 oz.)

9 ml (.30 oz.)

*1/2 cc/rev 1-1/2 ml (.05 oz.)

18 ml (.61 oz.)

1 cc/rev

3 ml (.10 oz.)

36 ml (1.22 oz.)

1-1/2 cc/rev 4-1/2 ml (.15 oz.)

54 ml (1.83 oz.)

2 cc/rev

6 ml (.20 oz.)

72 ml (2.43 oz.)

* Tubing provided with GeoCenter unit.

NOTE: 1cc = 1 ml

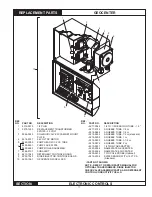

Figure 6-2

TIMe/DeLAY

POTENTIOMETERS

PuMP SPEED

POTENTIOMETER

NOTE: The best injection rates are achieved in the 10-20

revolution per minute range. It is recommended to select

the tubing that allows mid range operation.

6.7 Timed feed

In this mode of operation, the dispenser will activate for a

pre-set period of time. This would be used when dispensing

control is determined by volume,

refer to Figure 6-2.

Note that the TIME FEED and the SPEED CONTROL

modes can be used together. For example, if the injector

is activated during the fill cycle on a door type machine, by

setting the TIME FEED for just a few seconds longer than

the normal rinse time, this will be the maximum length of

time the product will be injected during the fill.

6.8 feed Delay

This feature can be used with either the SPEED CONTROL

or TIME FEED mode. This is adjustable from 0 to 10 seconds,

and delays the pump activation for that period of time after

the unit is activated,

refer to Figure 6-2.

Содержание GEOCENTER

Страница 2: ...This page intended to be blank...