13

www.ecoflam-burners.com

EN

420010813300

INSTALLATION

Electrical connections

!

WARNING:

Electrical wiring must be carried out with electrical supply disconnected and with burner switch in position OFF.

Electrical supply must correspond to the one shown on the burner label.

APPLICABLE STANDARD

The electrical connection work comprising

all the installation materials, terminals and

earth connections must be carried out in

accordance with the applicable

regulations. For the electrical installation of

the burner care must be taken to observe

the circuit diagram made out for the

furnace system.

The electrical connection of the burner and

instruments shall be entrusted to

authorized specialists only.

NOTE:

For the installation of the

connection cables care must be taken to

provide cable loops of sufficient length to

allow for the swing-out of the boiler door

and burner.

Make sure after the completion of the

electrical connection work to check the

wiring of the electrical system of the

burner. This should include a check of the

direction of rotation of the burner motor

(fan).

GENERAL WARNINGS:

All applicable electrical safety regulations

must be followed. Failure to correctly

dimension the suitable input power and

earth the equipment may cause damages

to person and compromise the correct

function of the burner therefore the

electrical system shall be checked by

qualifed personnel.

The manufacturer declines all

responsibility for modifcations or

connections different from those shown in

the electrical scheme.

Adapters, multiple plugs and extension

cables may not be used for the

equipment’s power supply.

An omnipolar switch in accordance with

current safety regulations is required for

the mains supply connection.

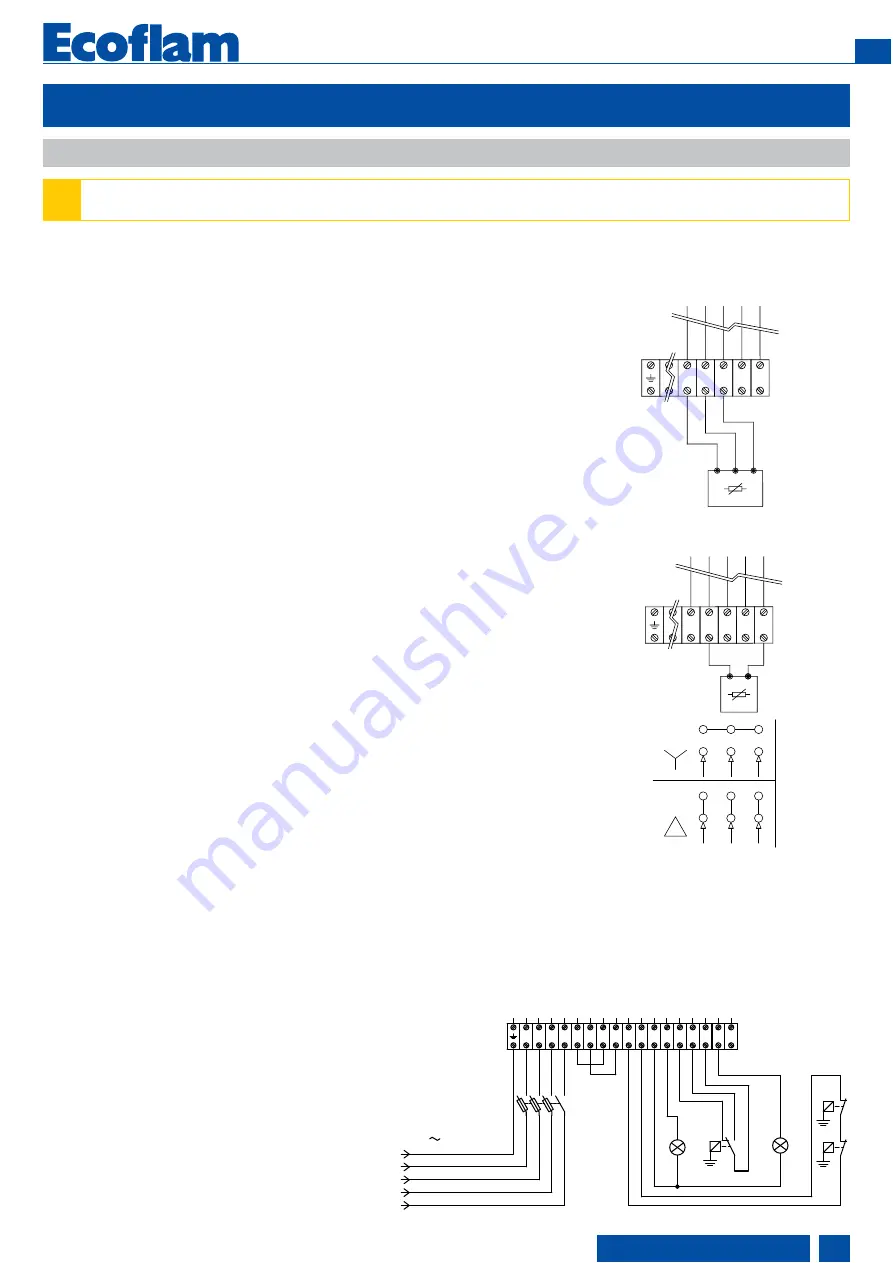

ELECTRICAL CONNECTION

1) of the burner

- Built-in electrical cabinet

Use cable gland in order to secure the

required level of protection. All the links,

power and control, are connected to the

terminal block of the cabinet. Provide

cables in sufficient length to secure the

rotation of the burner body according to

the assembly.

Check and adjust the size of the

contactors and thermal relays and the

wires section according to the motor and

supply voltage specs.

ATTENTION:

Wiring is not supplied.

The burners are produced with

connections suitable for power supply

380-400 V three-phase.

The burners with electric motors of an

output lower or equal to 3 kW can be

adapted to 220-230 V (please follow the

instructions on the backside); motors with

higher output can only work 380-400 V

three-phase. In case of request of burners

different from the above mentioned

standard, it is recommended to make

specific mention in the order.

Instructions: how to adapt electric

motors of an output lower or equal to 3

kW to 220-230 V power supply

It is possible to change the voltage of the

burner by operating as follows:

1. change the connection inside the

electric box of the motor, from star to delta

(see picture 1);

2. change the setting of the thermal relay,

referring to the absorption values indicated

in the motor nameplate. If necessary,

replace the thermal relay with another one

of suitable scale.This operation is not

possible on motors above 3 kW.

For more information, please contact the

Ecoflam staff.

LEGENDA

HLB: lock-out lamp

STAB: two stages thermostat

HLF: burner on flame lamp

STC: boiler thermostat

STS: safety thermostat

SA: active probe

SP: passive probe

T

P

P

T

P

T

STAB

9

Q

N

R

S

T

7

6

5

8

S

N

T

R

PE

50 Hz 400V

13

12

11

10

4

1

2

3

STC

HLB

STS

HLF

PROBES CONNECTION

9

13

12

11

10

SA

Q

BE

....

G

L

M

U1

ACTIVE PROBE CONNECTION

(FOR MODULATING VERSION)

12

13

11

9

10

S

P

Q

AE

...

M

B

PASSIVE PROBE CONNECTION

(FOR MODULATING VERSION)

230V

400V

fig.1

Содержание MAIOR P 500-1 PRE

Страница 31: ...31 www ecoflam burners com EN 420010813300...