32

Two: sensor and its related faults

1. Overview of faults

Short-circuit and open circuit of the temperature sensing bag, all of which have fault code display.

Indoor: environmental sensor failure, pipe temperature sensor failure.

Outdoor: the environmental sensor, outdoor pipe temperature sensor and exhaust temperature sensor are faulty.

Sensor resistance is abnormal

If the sensor resistance is abnormal or the sensor with wrong specification is replaced during maintenance, the fault code of the

sensor is generally not displayed, but it may cause abnormal protection frequency limiting, abnormal protection shutdown and other

related codes to be displayed. Faults caused by abnormal sensor resistance are invisible and complicated to deal with. Whether the

sensor resistance is normal or not can be rechecked in case of abnormal phenomena.

2. Cause

of

failure

When the sensor is open or short-circuited, the detection circuit voltage is close to the power supply voltage or 0V. The power

supply voltage of outdoor unit is 3.3V or 5V, and that of indoor unit is 5V.

3. Possible failure point

Poor contact and looseness of sensor terminal

Sensor circuit components loose, open circuit, virtual welding

Sensor resistance offset

Sensor circuit resistance offset, capacitor leakage

The sensor specification is wrong, for example, 10K is used as 50K

Abnormal controller chip

The sensor bulb is short-circuited with the shell or copper pipe

4. Fault handling flow

Three: indoor fan failure

1. Overview of faults

"F0" is displayed indoors, and F0 fault is mainly to prevent abnormal rotating speed from turning into fault of electronic control and

refrigerant circulation system.

2. Cause

of

failure

When the fan is turned on, the indoor main chip detects that the motor speed is lower than 300 rpm for 1 minute continuously

(through the fan feedback circuit), and the controller reports the fault of the internal fan.

3. Possible

failure

point

Whether the motor is installed correctly, whether the terminals are plugged firmly, whether the blades are stuck, whether the

eccentric tuyere of the sliding bearing in the rubber ring is blocked and the wind speed is too slow.

Fan starting capacitor is damaged

The internal controller is abnormal

The motor body is stuck and damaged (peculiar smell, open or short circuit of windings are abnormal. When measuring the winding

resistance, pay attention to distinguish whether the thermal protector acts due to the high temperature of the motor casing). Note: If

there is an "FO" fault in case of uncertainty, please check the fan blades and motor equipment and add proper lubricating oil.

4. Fault

handling

flow

NO

YES

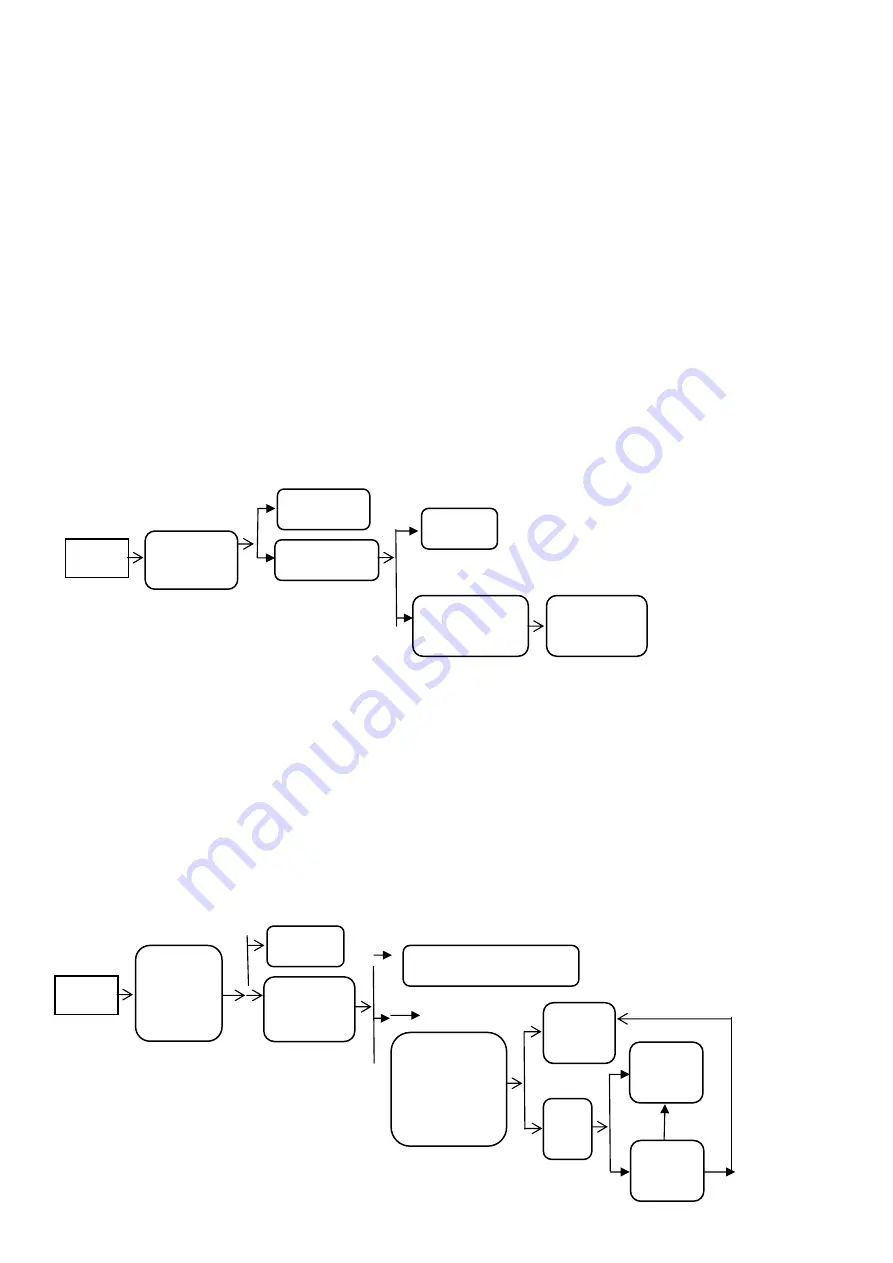

Sensor

failure

Is the terminal plug

loose or poor

contact

Reconnect and plug

in the terminals

Is the sensor resistance

normal

Replace sensor

Is the sensor lead broken

or short-circuited by other

devices or copper pipes

Replace the sensor

and readjust the

sensor routing

NO

NO

YE

S

YE

S

NO

YE

S

Internal fan

failure

Whether the

contact between

motor control

output and

feedback end is

firm

Reinsert the

terminals

Turn the blades by

hand to see if they

rotate smoothly

Re-assemble blades, motors and sliding

bearings correctly

Measure whether the

output voltage at the

control end of PG motor

is greater than 50V

within one minute after

being powered on again

and the air deflector is

turned on.

Replace the

main

controller of

the same

model

Motor

startin

g

Test whether

there is

feedback

signal

Replace the

internal

board

NO

NO

NO

YE

S

YE

S

YE

S

NO

Содержание CM2-H16/4DR2

Страница 1: ...Service manual FREE MATCH 50Hz R32 Models СM2 H16 4DR2 СM3 H22 4DR2 2022 06 ...

Страница 3: ...1 1 Summary and Features Outdoor Unit CM2H 1644A23 CM3H 2228A23 ...

Страница 11: ...9 4 Construction Views 4 1 Outdoor Unit CM2H 1644A23 Unit mm ...

Страница 12: ...10 CM3H 2228A23 Unit mm ...

Страница 27: ...25 8 Exploded Views and Parts List 8 1 Outdoor Unit Model CM2H 1644A23 ...

Страница 29: ...27 Model CM3H 2228A23 ...

Страница 47: ...41 ...