11

BrightFire 200, V1, Operating Instructions, Edition 09.15

Adjustment, Start

and Stop

BrightFire 200 Flame Adjustments

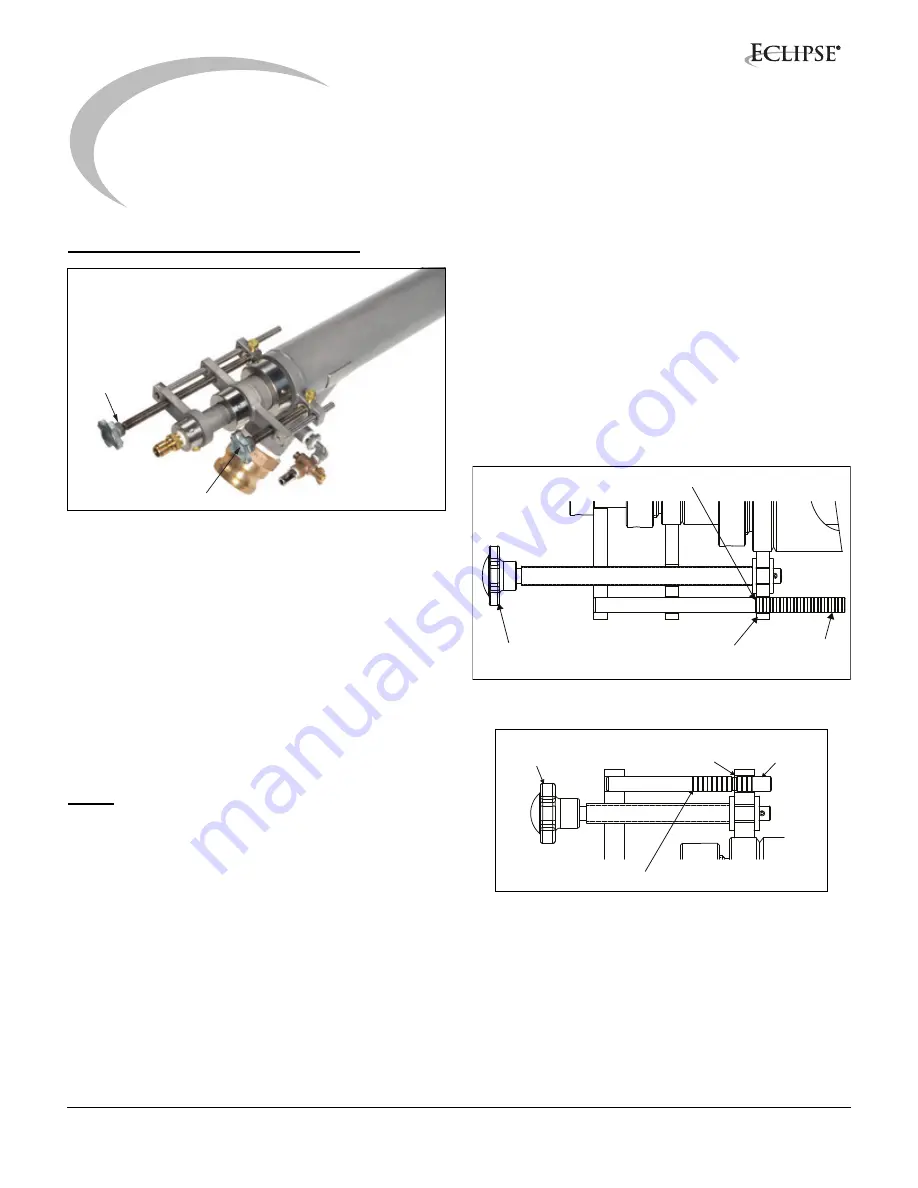

Figure 2.1. BrightFire 200 Adjustments

The BrightFire

®

200 has two adjustment valves, an area

adjustment (see Figure 2.1) and a flow adjustment. The

area adjustment (see Figure 2.2) changes the annulus

area between the inner and outer nozzles and is used to

control flame length. The flow adjustment (see Figure 2.3)

opens and closes an internal valve that changes the

distribution of gas flow between the outer and inner gas

tubes and is used to control where the heat from the flame

is released in the furnace. This can be changed

independently of the flame length. In addition, the firing

angle of the burner can be adjusted using the gimbal

mounting bracket adjustments to optimize gas flow into

the air stream. (Refer to Gimbal Bracket Info Guide 1113.)

NOTE:

Mounting bracket adjustments should only be

done on the off-firing side to prevent natural gas from

deflecting back into the port area if the seal between the

socket plate and burner nozzle is lost.

To adjust the burners once the furnace is at, or near,

normal operating conditions, begin by adjusting the area

adjustment to set the flame to the desired length.

Increasing the annulus area by moving the adjustment

back (counter-clockwise rotation of the adjustment knob)

will lengthen the flame while moving the adjustment

forward (clockwise rotation of the adjustment knob) will

shorten the flame.

To read the indicator rod positions for the area and flow

adjustments, the first ring starting from the back of the

burner indicates position ‘1’. The position is indicated by

the ring that is flush with the back face of the adjusting lug.

Position 1 on the area adjustment rod indicates the inner

nozzle is all the way forward within the outer gas annulus,

flush with the face of the outer nozzle. Position 1 on the

flow adjustment rod indicates the inner flow valve is

closed with the maximum amount of gas flow through the

center jet. Refer to figures 2.2 and 2.3 which show an area

adjustment at position 1 and a flow adjustment at position

10.

Figure 2.2. Area Adjustment Mechanism

Figure 2.3. Flow Adjustment Mechanism

The flame is typically set about 2/3 of the width of the

furnace (length for end fired furnaces). The flame should

not impinge on the far wall or fire into the opposite side

port. Excessive lofting of the flame should also be avoided

to prevent damage to the furnace crown. Flames should

be above the glass or batch pile surface, and should not

be too low to prevent dust kick-up and batch carry-over

into the opposite port.

Area

Adjustment

Flow

Adjustment

Adjusting

Lead Screw

Position Indicator:

Read Markings Here

Position

Indicator

Position 1

Adjusting

Lead Screw

Position Indicator:

Read Markings Here

Position

Indicator

Position 1

4