TRACKSTAR

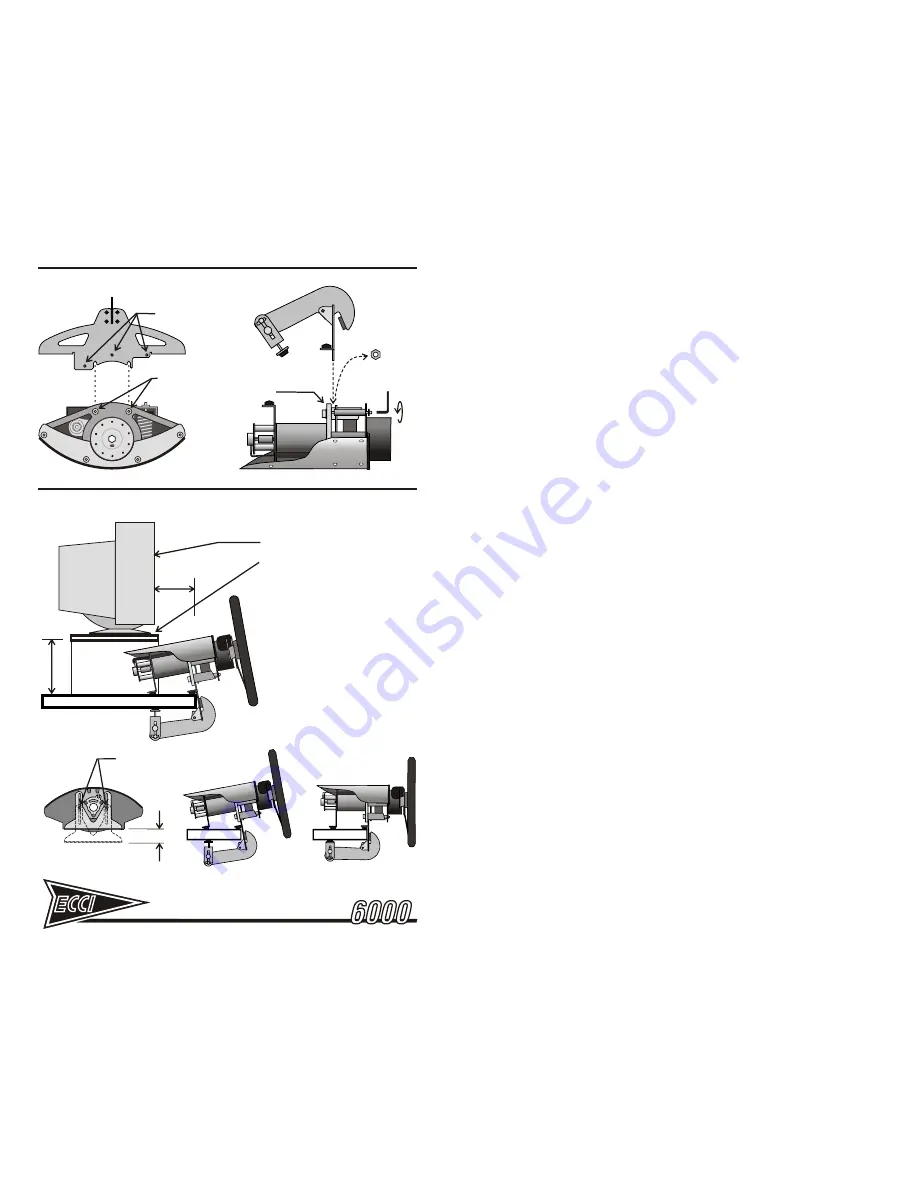

Figure 3 - TABLE BRACKET INSTALLATION

CHASSIS TUBE BOLTS

BRACKET MOUNT

SCREW HOLES

Figure 4 - TABLE EDGE MOUNTING AND ADJUSTMENT

MONITOR

MONITOR SHELF WITH 8+

6 IN.

8”

M

IN

.

HEX KEY

CENTRAL STRUCTURAL PLATE

INCHES OF CLEARANCE

REMOVE

2 NUTS

REAR LEG

ADJUSTMENT

SCREWS

ELEVATION OF REAR LEG

SETS ANGLE OF UNIT

1. [Figure 5]. Begin assembly by putting two screws through the steering wheel

at the ten and two o’clock position. Hold the heads in place on the wheel

with a piece of masking tape. Note that the flanged button retaining ring

must be placed between the steering wheel and the shift paddle set. The

raised flange of this ring must point towards and fit into the large central hole

in the paddle set. Place the paddle set over the screws making sure the

button wires are in their slots. Once the paddles are close to the wheel. pull

the paddle set wires towards you through the center hole of the wheel.

2. Next position this assembly over the steering unit hub making sure the wheel

is upright. Guide the two screws into their respective holes. Pull the hub

wires and connectors towards you through the center of the wheel/paddle

assembly. Next remove the masking tape and turn the screws in gently

making sure before tightening that the paddle button wires are not in danger

of being pinched. The wheel should be centered and not cocked to one side.

If it is tilted, remove the screws and use the next set of hub holes to counter

the tilt. Turn the screws in until snug. Then install the remaining three screws

and finally tighten all five screws progressively using the supplied hex

wrench until tight.

3. Connect the button wires to the hub connectors as shown in Figure 5. Wire

colors do not matter, the paddles will function any way they are plugged in.

Carefully arrange the wires within the hub cavity such that none are pinched

when the center logo button is installed. The center logo button is installed

by engaging the four prongs of the button through the button retaining ring

that sits behind the wheel. Push the button firmly until flush to the wheel.

1.4

WHEEL ANGLE ADJUSTMENT

The final step of wheel unit setup is to adjust the angle of the steering wheel to

your preference. This is done by loosening the rear leg screws [Figure 4] until the

rear leg can be moved up or down. Making this adjustment will also require

loosening the bracket tensioning bolt under the mounting surface [Figure 2].

The tensioning bolt and the rear leg essentially ‘pinch’ the mounting surface from

bottom and top to hold the unit securely. To tilt the wheel more towards vertical,

the rear leg must be extended downward and the bracket bolt must be backed

down. To tilt the wheel more forward the rear leg must be raised and the bracket

bolt extended.

If a substantial change of wheel mounting angle is desired, it will be necessary to

loosen the pivot set screw and the tensioning pivot nut [Figure 2]. For proper

performance of the mounting system, the bracket tensioning bolt must be vertical

and perpendicular to the underside of the mounting surface.

1.5

COCKPIT MOUNTING

In addition to removable desktop mounting, the TRACKSTAR 6000 wheel unit is

easily adapted to a custom driving cockpit. When attaching the unit permanently

to a fixed framework, the table mounting bracket need not be used. The unit can

be mounted directly to the cockpit sub-frame in its upright orientation or inverted

under a monitor shelf.

In either configuration, the most critical requirement is that the unit is

attached at both the front and rear. Remove the rubber feet from the rear

leg and fasten to a rigid support bracket through the screw holes. It is

important to use BOTH front