FLDS

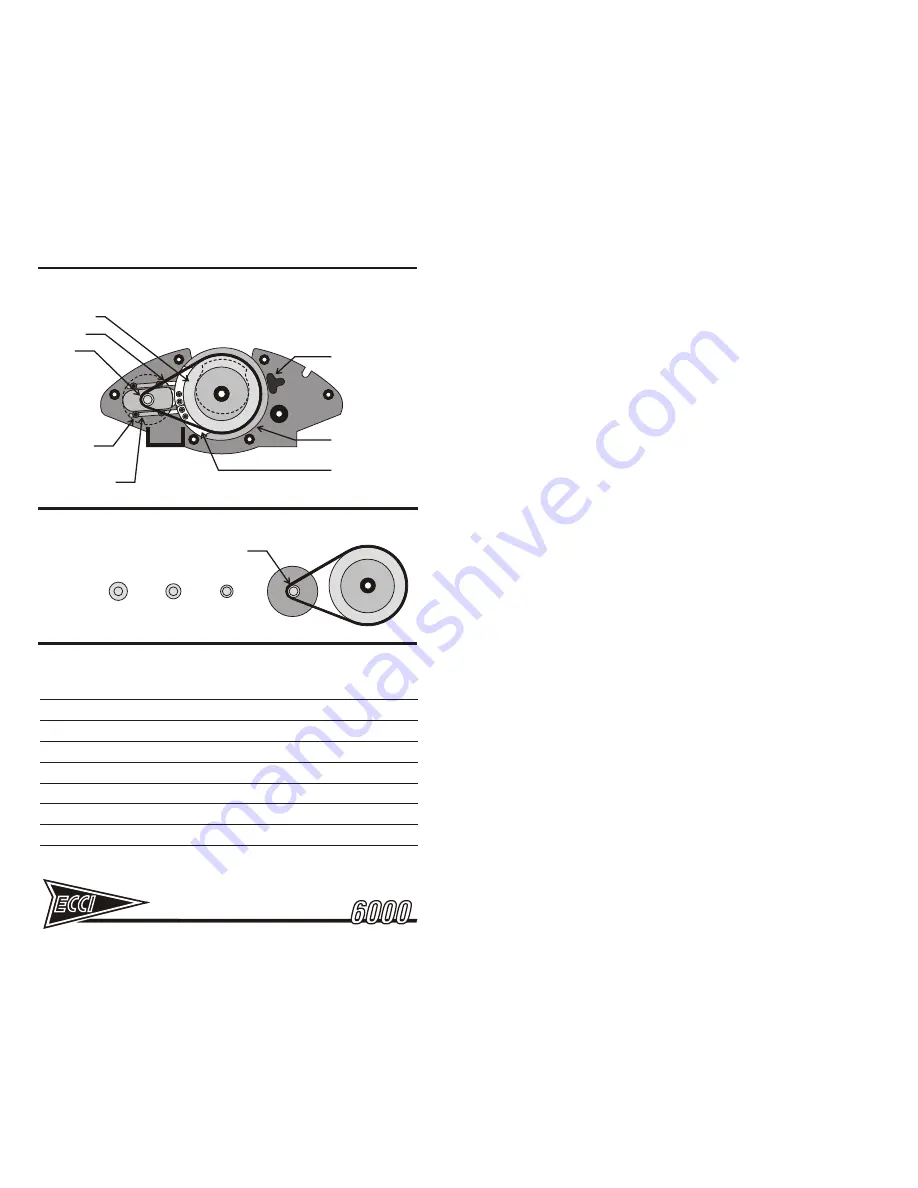

Figure 26 - FLUID DAMPED STEERING SYSTEM

Figure 27 - DAMPING ADJUSTMENT OPTIONS

DRIVE BELT

DRIVE PULLEY

DAMPER

PULLEY

DAMPER BELT

TENSIONING SLOTS

FLDS ROTARY

FLUID DAMPER

STANDARD

LIGHT

LIGHTEST

RESISTANCE CAM, FOLLOWER ARM,

AND SPRING ASSEMBLY REMOVED

DAMPER

PULLEY

FROM THIS VIEW FOR CLARITY

NOTE:

WHEEL TRAVEL

LIMITER

TRAVEL

ADJUSTMENT STOPS

MAIN STEERING

STOP

TRACKSTAR

NOTES:

6.0

POT REPLACEMENT AND POT SETUP

The following steps are required only if replacing pots. Pots are the electro-

mechanical components that sense the position of the wheel or pedal and

translate this to electrical information read by the ECCI USB HD system. These

are long-lived but will eventually wear out. The sign of pot wear is notchy,

inconsistent response at the same spot in the axis travel. If the problem is

variable, occurring in different areas of travel at different times, the problem may

instead be a loose pot shaft nut or a loose wire connector. Pots that do not

maintain calibration can also be caused by a loose not. Rule these things out first

before ordering new pots.

If you need new pots,

use only ECCI pots

. ECCI pots are specifically made for

ECCI controllers and have the required resistance range and performance

characteristics. ECCI cannot warrant the performance of any system not using

ECCI pots. When ordering replacements, order the ECCI HP Racing pots. The

USB HD needs a 100K HP pot for the steering and 50K HP pots for the pedals.

Unless you have a rare premature failure (under 1 year), ECCI recommends

replacing the entire set rather than the single pot with the problem.

6.1

STEERING POT REPLACEMENT

Replacing the wheel pot is a simple procedure. Refer to Figures 6 and 28 for

illustrations. The steps to perform replacement are as follows:

1. Mount the wheel unit securely to a tabletop with the clamp. Unplug the USB

cable from your computer. Remove the ten screws which secure the cover of

the wheel unit to the chassis. Lift the cover and set aside.

2. Leave the pedal unit and its associated ground cable attached to the wheel

unit. This will provide ground protection for the circuit board. If your pedal

unit is not attached, use the ground cable originally supplied with your

driving system to connect the steering unit chassis to a screw on the

computer case, a screw attached to the faceplate of an electrical outlet, or

other suitable ground.

3. Carefully pull the wire connectors from the pot terminals. Make sure to pull

on the connector body, not the wire.

4. Using a 3/32” hex key, loosen the steering shaft clamping screw located on

the pot connector [Figure 28]. Next use a philips screwdriver to remove the

pot bracket screws. The pot bracket assembly can now be removed.

5. Loosen the pot shaft clamping screw on the pot connector. Slide the

connector free and remove the pot retaining nut and the pot will fall free.

6. Mount the new replacement pot, into the pot bracket using the nut and lock

washer. Make sure the pins in the pot body engage the slots in the bracket.

Turn the retaining nut down until tight. Avoid over-tightening as this can

damage the pot. Turn the pot shaft so the slot is vertically in-line with the

center terminal of the pot. The slot must be vertical for the next step.

Next examine the pot connector. Note that at each end, the clamping

screw tightens a split in the ends of the connector. The split in the

connector must be horizontal with the clamping screws facing upward,

Making sure the pot