27

Overview

Flame monitor

IR Flame Detector FFS 06

For IR flame detectors and UV flame

detectors, the minimum response thres-

holds are 15 mV AC and 25 mV AC,

respectively. Refer to the technical

documentations of the flame monitors

for further commissioning instructions.

Note: The UV flame detectors are not

provided with this sensitivity adjust-

ment. They are optimized by aligning to

the flame to be monitored in the best

possible way using the measurable

signal voltage on the measuring line.

Criteria for flame detectors

Detector type

spectral radiation range

application - fuel

FFS 06 UV-1

260-400nm

oil, gas

FFS 06 UV-2

210-380nm

oil, gas (special gases such as

refinery and high furnace gases)

FFS 06 (IR)

1200-2800nm

oil, gas, furnaces with heavy flue

gas recirculation, waste gases

with yellowish colouring without

UV radiation

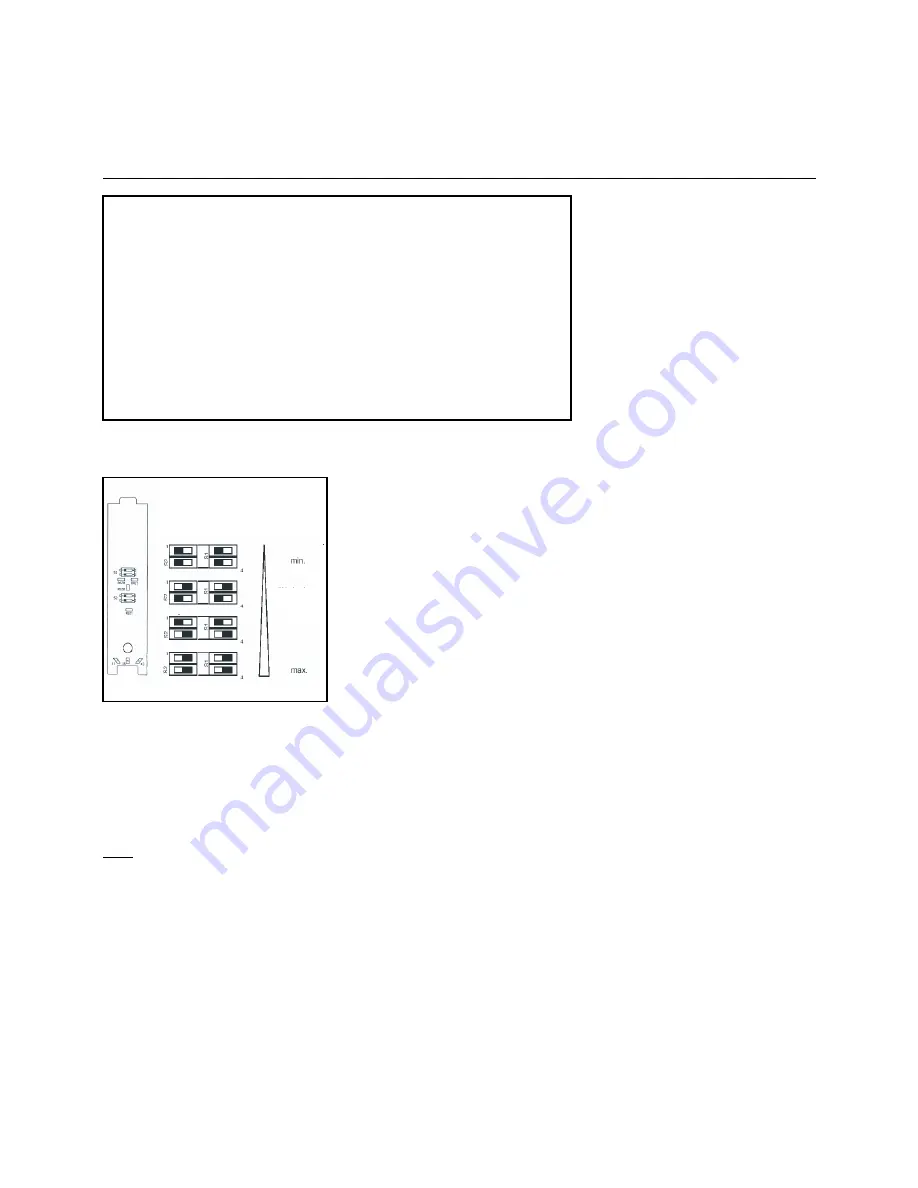

Sensitivity

Adjustment to be made on switches

S1 and S2 which are accessible

after opening the detector housing.

factory

configur-

ation

Figure 2

Assembling and commissioning of

flame detectors

The flame detector should be installed

in the provided mounting at an inspec-

tion opening of the burner in a way that

the burner flame to be monitored is

clearly visible in the overall operational

range of the furnace. The sensitivity of

the IR flame detector FFS 06 to the bur-

ner flame can be adapted via the thres-

hold switch in the flame detector. In

doing so, the sensor housing should be

unscrewed and the setting on the thres-

hold switches made according to the

Figure (2).