Operating instructions

K3G560-AP23-01

Translation of the original operating instructions

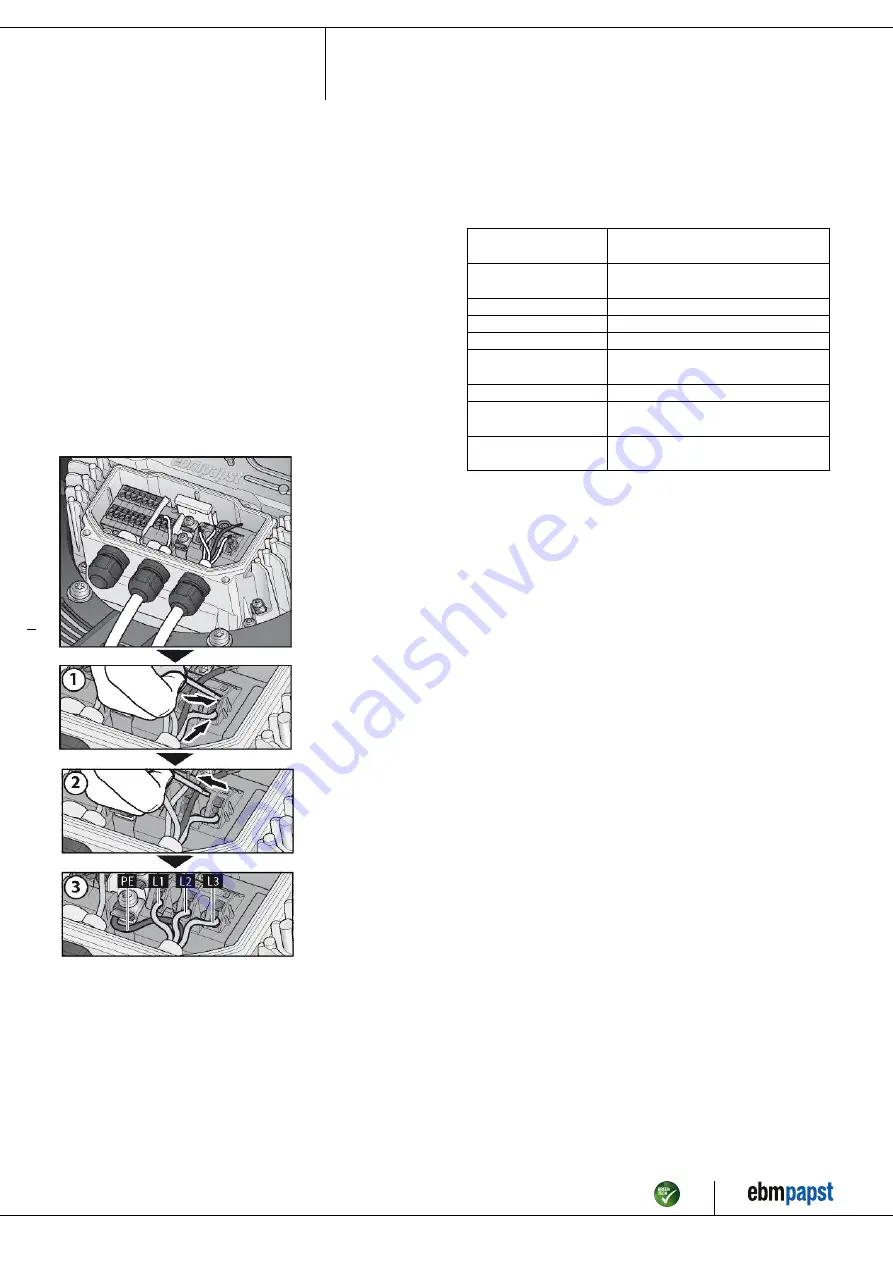

4.3.2 Connecting cables with terminals

WARNING

Terminals and connections have voltage even with a

unit that is shut off

Electric shock

→ Wait five minutes after disconnecting the voltage at all poles

before opening the device.

;

Remove the cap from the screwed cable gland.

Remove the cap only in those places where cables are inserted.

;

Mount the screwed cable glands with the seal inserts provided in the

terminal box.

;

Insert the line(s) (not included in the standard scope of delivery) into

the terminal box.

;

First connect the "PE" (protective earth) connection.

;

Connect the lines to the corresponding terminals.

Use a screwdriver to do so.

During the connection work, ensure that no cables splice off.

Fig. 2: Connecting the wires to terminals

;

Seal the terminal box.

4.3.3 Cable routing

No water may penetrate along the cable in the direction of the cable gland.

4.4 Factory settings

Factory settings with which the device is pre-set by ebm-papst.

Control mode

parameter set 1

PWM controlling

Control mode

parameter set 2

PWM controlling

Fan / device adress

1

Max. PWM / %

100

Min. PWM / %

5,1

Save set value to

EEPROM

Yes

Set value control

Analogue (linear)

Control function

parameter set 1

Positive (heating)

Control function

parameter set 2

Positive (heating)

Item no. 50653-5-9970 · ENG · Revision 82549 · Release 2014-05-08 · Page 8 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com