Operating instructions

K3G560-AP23-01

Translation of the original operating instructions

NOTE

Water penetration into leads or wires

Water enters at the cable end on the customers side and can

damage the device.

→ Make sure that the cable end is connected in a dry

environment.

Connect the device only to circuits that can be switched off

using an all-pole disconnecting switch.

4.2.1 Prerequisites

;

Check whether the data on the type plate agree with the connection

data.

;

Before connecting the device, ensure that the supply voltage matches

the operating voltage of the device.

;

Only use cables designed for current according to the type plate.

For determining the cross-section, follow the basic principles in

accordance with EN 61800-5-1. The protective earth must have a

cross-section equal to or greater than the outer conductor cross-

section.

We recommend the use of 105°C cables. Ensure that the minimum

cable cross-section is at least

AWG26/0.13 mm².

Earth wire contact resistance to EN 61800-5-1

Compliance with the impedance specifications to EN 61800-5-1 for the

protective earth circuit must be verified in the end application.

Depending on the installation situation, it may be necessary to install an

additional protective earthing conductor via the additional protective earth

connection point available on the device.

The protective earth connection point is located on the housing and has

a protective earth symbol and a bore hole.

4.2.2 Power supply connection, fuse protection

Assignment of conductor cross-sections and the fuse protection required

for them (overload protection only, no device protection).

Nominal

voltage

Safety

fuse

Automatic

circuit

breaker

Wire

cross-

section

Wire

cross-

section

VDE

UL

VDE

mm²

*AWG

3/PE AC

380 - 480

VAC

16 A

15 A

C16A

1.5

16

3/PE AC

380 - 480

VAC

20 A

20 A

C20A

2.5

14

3/PE AC

380 - 480

VAC

25 A

25 A

C25A

4.0

12

3/PE AC

380 - 480

VAC

32 A

30 A

C32A

6.0

10

* AWG = American Wire Gauge

4.2.3 Idle current

Because of the EMC filter integrated for compliance with EMC

limits (interference emission and interference immunity), idle

currents in the mains cable can be measured even when the

motor is at a standstill and the mains voltage is switched on.

●

The values lie in a range of typical < 250 mA.

●

The effective power in this operating state (readiness for operation) is

simultaneously at typical < 5 W.

4.2.4 Residual current operated device

Only universal (type B or B+) RCD protective devices are

permitted. Like frequency inverters, RCD protective devices

cannot provide personal safety while operating the device.

When switching on the power supply of the device, pulsed

charge currents from the capacitors in the integrated EMC filter

can lead to the RCD protective devices triggering without

delay. We recommend residual current devices with a trigger

threshold of 300 mA and delayed triggering (super-resistant,

characteristic K).

4.2.5 Leakage current

For asymmetrical power systems or if a phase fails, the

leakage current can increase to a multiple of the nominal value.

4.2.6 Locked-rotor protection

Due to the locked-rotor protection, the start-up current (LRA) is

equal to or less than the nominal current (FLA).

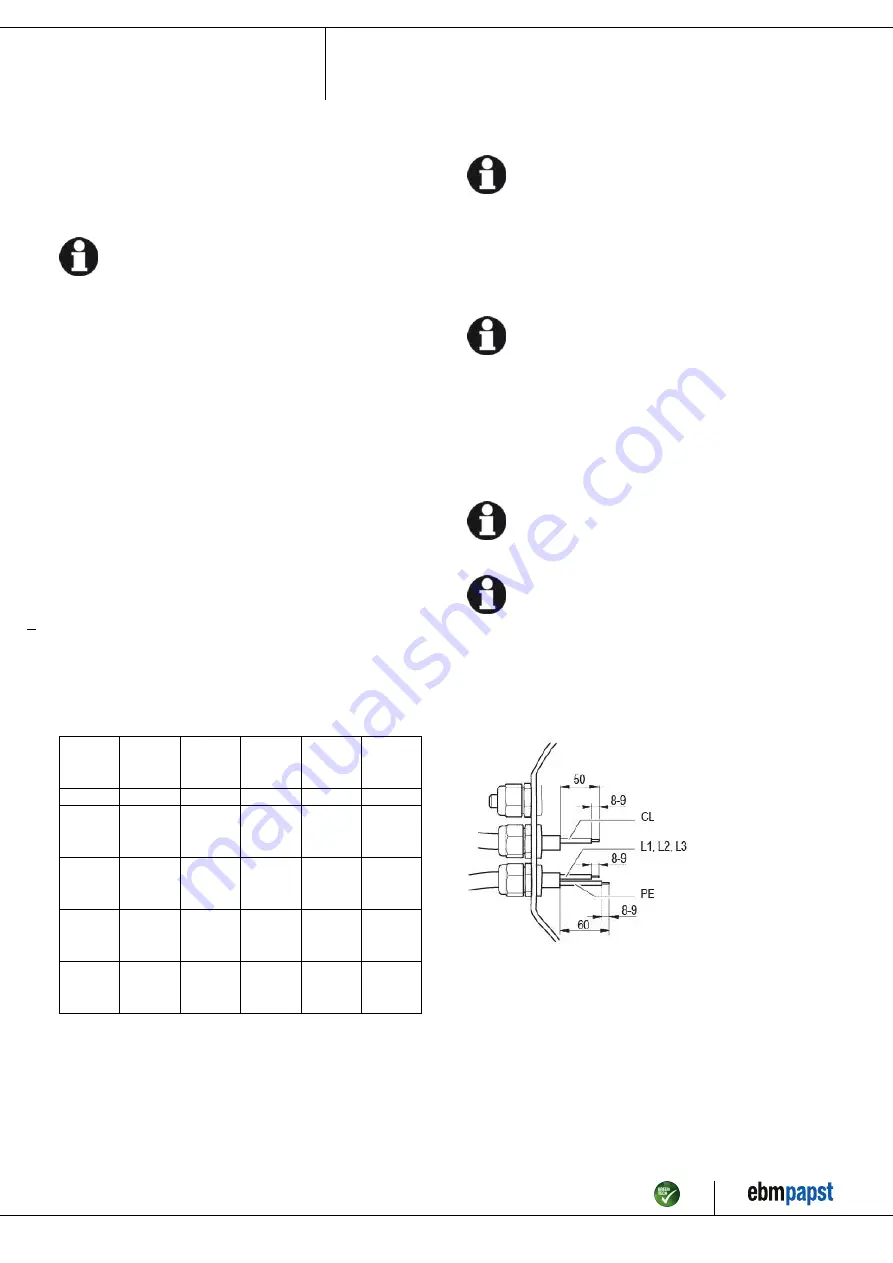

4.3 Connection in terminal box

4.3.1 Preparing connection lines for the connection

Strip the cable just enough so that the screwed cable gland is tight and

the terminals are relieved of strain. Tightening torque, see chapter 3.1

Product drawing.

Fig. 1: Recommended stripping lengths in mm (inside the terminal box)

Legend: CL = control lines

Item no. 50653-5-9970 · ENG · Revision 82549 · Release 2014-05-08 · Page 7 / 12

ebm-papst Mulfingen GmbH & Co. KG · Bachmühle 2 · D-74673 Mulfingen · Phone +49 (0) 7938 81-0 · Fax +49 (0) 7938 81-110 · [email protected] · www.ebmpapst.com