8

Place tip of applicator

at top of threaded

portion.

Apply 3 or 4

drops in

each hole.

Figure 14

Mounting

Flange

Seal

Driver

Seal

Tube

Back-up Ring

(No Back-up

Ring -008)

Seal Installation Tool

Figure 13

Exclusion

Seal

Shaft

Pressure

Seal

Figure 12

Break Sharp

Corner (see

above note)

Mounting Flange Cross-section

15

°

30

°

,25/,51

[.010/.020]

Inspect for

cracks in this

area of seal

seat

General Purpose Motors

S Series

Reassembly

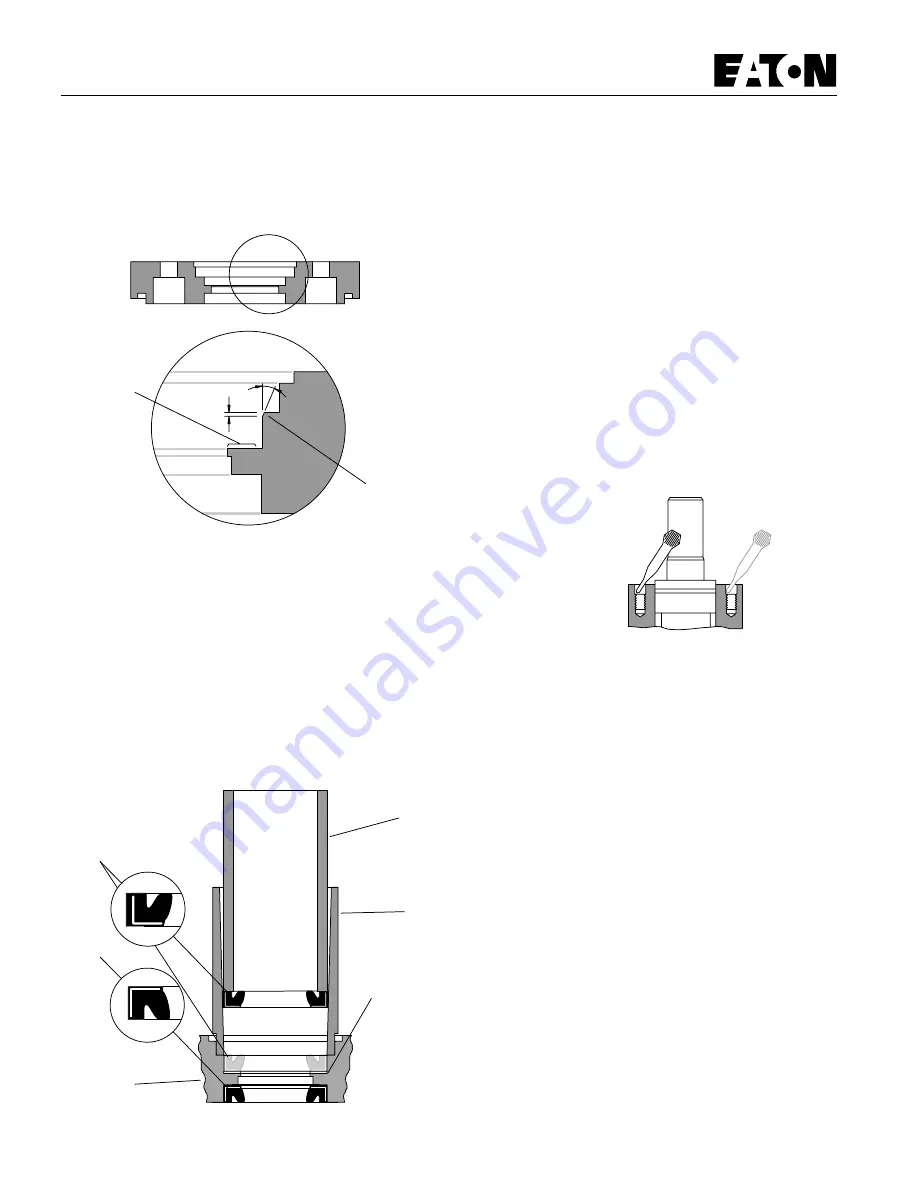

Important: Prior to installing high pressure shaft seal it is necessary

to break the sharp corner of the flange seal seat, see Fig. 12. Use

400 grit paper to break corner.

22 Clean mounting flange of all loose metallic chips, particles, dirt or

other contamination, including oil. During cleaning, visually check seal

seat in mounting flange for scratches or other marks that might

damage the pressure seal. Check for cracks in flange that might cause

leakage, see Fig. 12.

Important: If a pressure seal installation tool is not available,

temporarily install flange without seals. Then install 2 cap screws

to secure flange to housing. Install seals in flange, and apply

loctite, after you reassemble Gerotor end of motor (see step 41 thru

45 page 11).

Note: If you have a pressure seal installation tool, continue

reassembly, starting with step 23.

23 Lubricate I.D. of seal tube and 0.D. of shaft pressure seal with a

light film of clean petroleum jelly. Align small I.D. end of seal tube with

seal seat in mounting flange. Install back-up ring and pressure seal in

tube—lips of seal face up—see above. Then insert seal driver in tube

to firmly push (by hand with rotating action) seal in seal seat.

Important: After installing seal in flange, examine seal condition. If

cut, damaged, or improperly installed, you must replace it before

continuing reassembly.

24 Install dust seal in flange, see Fig. 15. Press the dust seal into place

carefully. To eliminate damage to rubber portion or distortion of metal

container use a tool (flat-round face 35-41mm[1.37 to 1.62 inch]

diameter) which provides proper guiding and positioning.

25 Install 1.94 inch [50mm] I.D. seal in flange.

Caution: Do not use excessive amount of Loctite.

26 Apply 3 or 4 drops of Loctite adhesive (Loctite no. 601 sealant) at

top of threads in each of 4 holes in housing, see Fig. 14. Do not allow

parts with Loctite applied to surface to contact any metal parts other

than their proper assembly. Wipe off excess Loctite from housing face,

using a non-petroleum base solvent. Do not apply Loctite to threads

more than 15 minutes before installing screws. If housing stands for

more than 15 minutes, repeat application. No additional cleaning or

removal of previous Loctite is necessary.

Содержание Char-Lynn S Series

Страница 2: ...2...