IOM 2596 Cast 10”–16” | Fabricated 10”-36” 10/2011

REV A.

Page 5 of 15

Eaton Filtration, LLC, 44 Apple Street, Tinton Falls, NJ 07724 | www.eaton.com/filtration | Phone: 732-212-4700

Installation, Operation & Maintenance Manual

Model 2596 Self-Cleaning Strainer

Cast 10” to 16” and Fabricated 10” to 36”

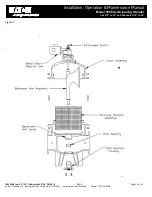

NOTE

: It is not necessary to remove the straining

element. Cleaning by scrubbing the straining

element with a bristle brush or spraying with a high

pressure hose. If necessary, the straining element

may be steam cleaned

.

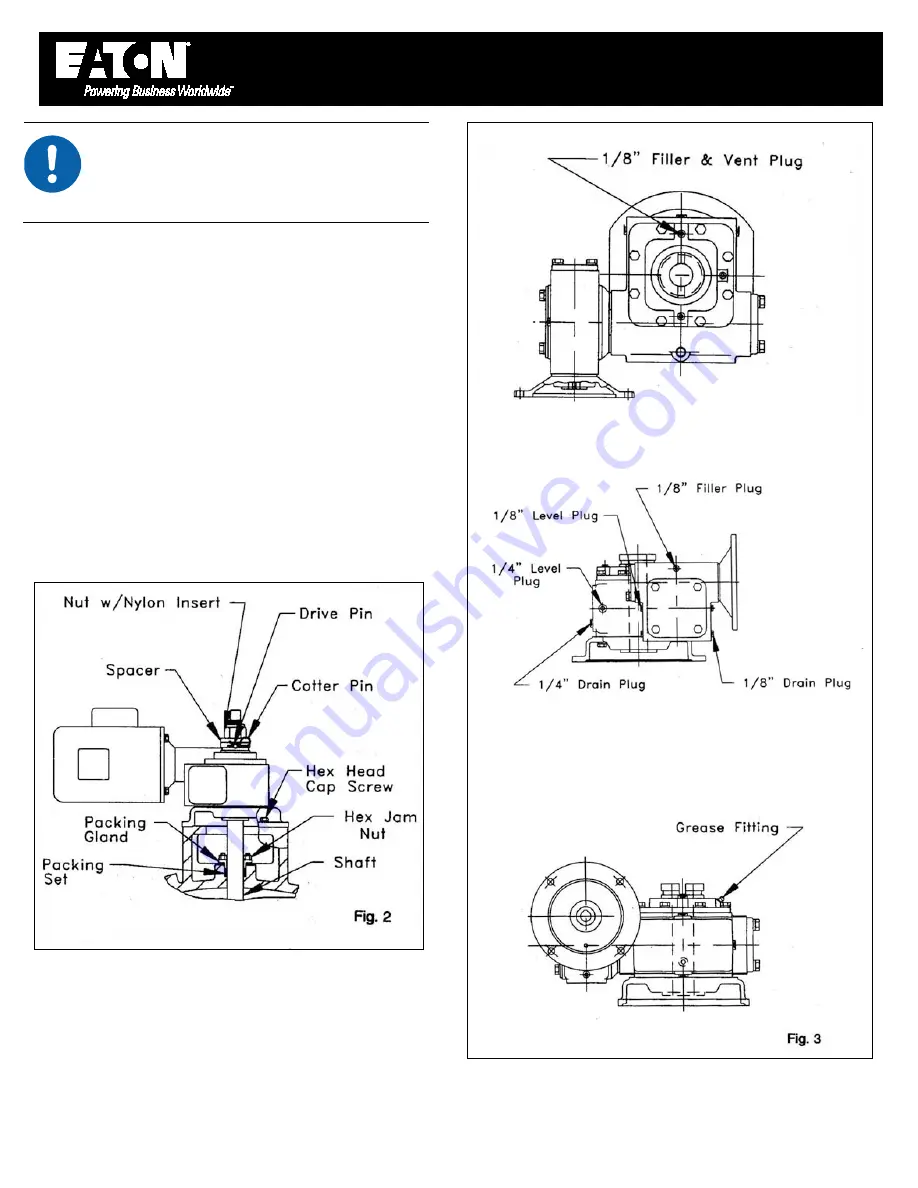

REDUCER

MAINTENANCE

After the initial 250 hours of operation, drain the reducer oil

while warm and flush the case with a light flushing oil. Refill to

the proper level with the appropriate lubricant (use Mobil

Cylinder Oil 600W or equal).

Check the level at 500 hour intervals, drain and refill at 2500

hour intervals, or every six months, whichever occurs first.

Check both housings on double reduction reducers.

For operation in the 15° to 60° F range use a lubricant

conforming to AGMA Specification No. 7 compound.

For 50° to 100° F operation use AGMA Specification No. 8

compound. Grease lubricated bearings should be lubricated at

500 hour intervals with Mobilux Grease #2 or equal.