1

200 A Fused Loadbreak Elbow Connector Replacement Fuse

InstallatIon InstructIons

MN132021EN November 2016

WARNING

Capacitive Test Point Operating Instructions: Use only

voltage indicating instruments specifically designed for

test points . Use of conventional voltage sensing devices

may provide false “No Voltage” indications .

The test point must be dry and free of contaminants

when checking for voltage . After indication is taken:

clean, dry, and lubricate the test point cap with silicone

grease and assemble to the test point .

Always consider the termination to be energized until

the test point “No Voltage” indication is confirmed by

other means . Failure to comply could result in death or

severe personal injury .

WARNING

All associated apparatus must be de-energized during

any hands-on installation or maintenance . Failure to

comply could result in death, severe personal injury and

equipment damage .

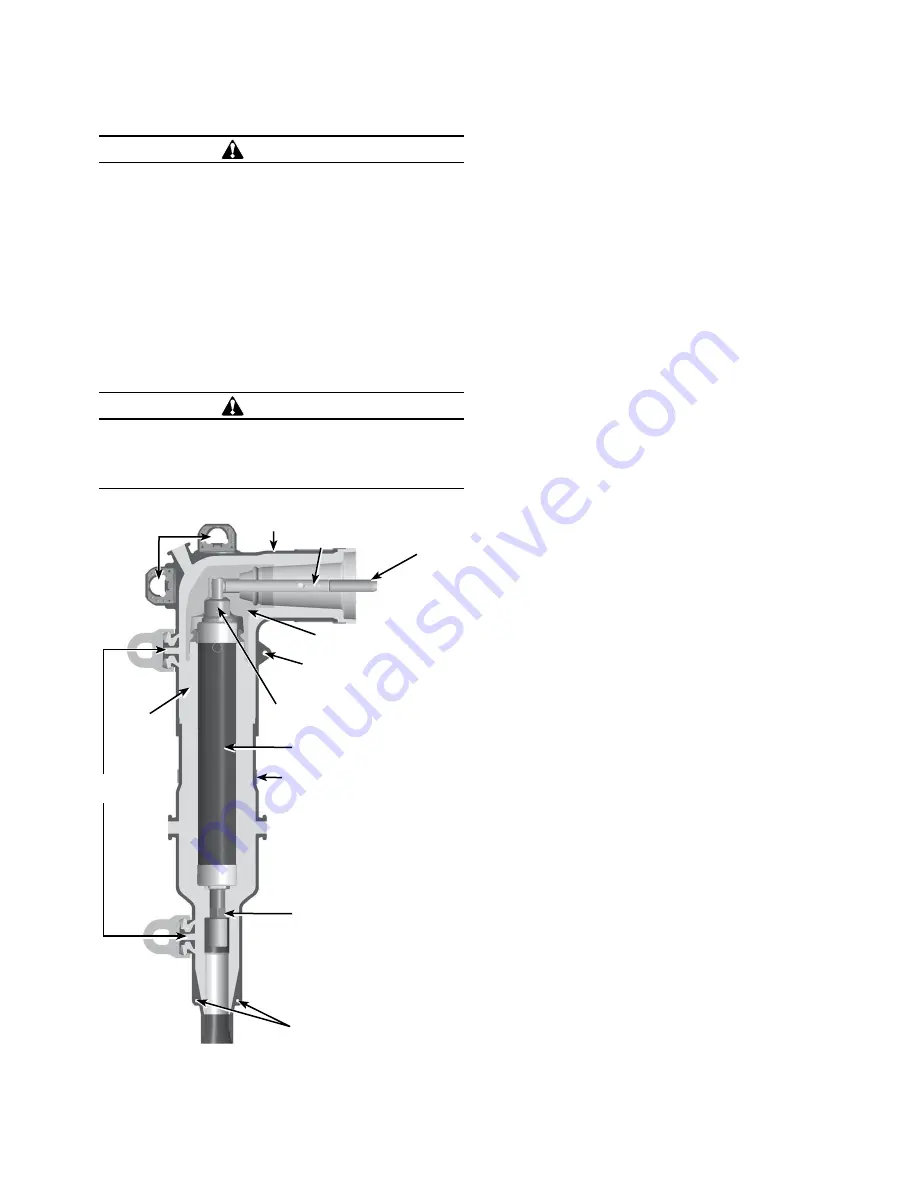

Semi-Conducting Shield

Semi-Conductive Insert

Current-Limiting Fuse

Coppertop Connector

Drain Wire Tab

Loadbreak Band

Probe Adapter

Drain Wire Tab

EPDM

Insulation

Loadbreak Probe

Arc

Follower

Pulling Eye

Test

Point

Figure 1 . Line illustration of 200 A 25 kV Fused Elbow .

Product Information

Introduction

The 200 A, 15 and 25 kV Class Fused Loadbreak Elbow

Connectors from Eaton combines a fully-shielded and

insulated plug-in termination with fullrange current-limiting

fuse protection. The Fused Loadbreak Elbow Connector

provides a convenient and cost effective means to adding

fused protection to underground distribution systems, for

connecting underground cables to transformers, switching

cabinets and junctions equipped with loadbreak bushings.

Read This Manual First

Read and understand the contents of this manual and follow

all locally approved procedures and safety practices before

installing or operating this equipment.

Additional Information

These instructions cannot cover all details or variations

in the equipment, procedures, or process described nor

provide directions for meeting every possible contingency

during installation, operation, or maintenance. When

additional information is desired to satisfy a problem not

covered sufficiently for the user’s purpose, please contact

your Eaton representative.

Acceptance and Initial Inspection

Each current-limiting replacement fuse is completely

inspected and tested at the factory. It is in good condition

when accepted by the carrier for shipment. Upon receipt of

the current-limiting replacement fuse, inspect the connector

thoroughly for damage and loss of parts incurred during

shipment. If damage or loss is discovered, file a claim with

the carrier immediately.

Handling and Storage

If the current-limiting replacement fuse is to be stored for

an appreciable time before installation, provide a clean,

dry storage area. Locate the replacement fuse so as to

minimize the possibility of physical damage.

Quality Standards

ISO 9001 Certified Quality Management System.