12. Air Conditioner Operations and Performance

The operating temperature range under which the unit runs stably are given in

below table.

Do not set

the temperature

too low

Caution

• The unit performs stably in the temperature range given in above table.

If the indoor temperature is outside the unit's normal operating range, it

may stop running and display an error code.

To ensure the desired temperature is achieved efficiently, ensure that:

• All windows and door are closed.

• The airflow direction is adjusted to work in running mode.

• The air filter is clean.

Please note how you can best save energy and achieve the best

cooling/heating effect.

Regularly clean air filters inside indoor units.

Avoid too much outdoor air coming into air-conditioned spaces.

Close doors and windows.

Check

regularly

Note that outlet air is cooler or heater than set room temperature. Avoid

direct exposure to outlet air as it may be too cool or hot.

Maintain a proper air distribution. Air outlet louvers should be used to adjust

the direction of outlet airflow, as doing so might ensure more efficient

operation.

• During heating operation, horizontal airflow will aggravate the

uneven distribution of room temperature.

• The louver direction: horizontal airflow is recommended

during cooling operation. Note the downward air flow will

cause condensation on the air outlet and louver surface.

Caution

13. Adjusting Air Flow Direction

Since warmer air rises and cooler air falls, the distribution of

warmed/cooled air around a room can be improved by positioning the

unit's louvers. The louver angle can be adjusted by pressing the

[SWING] button on the remote controller.

14. Maintenance

Caution

• Before you clean the air conditioner, ensure it is powered off.

• Check that the wiring is undamaged and connected.

• Use a dry cloth to wipe the indoor unit and remote controller.

• A wet cloth may be used to clean the indoor unit if it is very

dirty.

• Never use a damp cloth on the remote controller.

• Do not use a chemically treated duster on the unit or leave this

type of material on the unit to avoid damaging the finish.

• Do not use benzene, thinner, polishing powder, or similar

solvents for cleaning. These may cause the plastic surface to

crack or warp.

Method for cleaning the air filter

a. The air filter can prevent the dust or other particles from

entering the unit. If the filter is blocked, the unit will not work

well. Clean the filter every two weeks when you use it regularly.

b. If the air conditioner is positioned in a dusty place, clean the

filter often.

c. Replace the filter if it is too dusty to clean (the replaceable air

filter is an optional fitting).

Caution

• The control box cables originally connected to the electrical

terminals on the main body must be removed, as indicated

above.

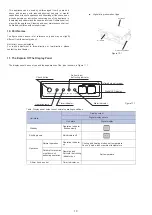

1. Dismantle the air filter(Refer to Figure 14.1).

2. Clean the air filter

Dusts will accumulate on the filter along with the unit operation,

and need to be removed from the filter, or the unit would not

function effectively.

Clean the filter every two weeks when you use the unit regularly.

Clean the air filter with a vacuum cleaner or water.

a. The air intake side should face up when using a vacuum

cleaner. (Refer to Figure 14.2)

b. The air intake side should face down when using clean water.

(Refer to Figure 14.3)

For excessive dusts, use a soft brush and natural detergent to

clean it and dry in a cool place.

20

•

Please release pressure before disassembly.

Cooling mode

Heating mode

17

32

°C

(DB)

15

27

°C

(DB)

Indoor temperature

Indoor humidity

(a) Condensation will form on the unit surface and water dripping

out of the unit when the indoor humidity is beyond 80%

≤80%

(a)

Содержание Gama CND

Страница 2: ......