Caution

11

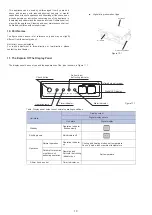

6. Air Duct Installation

6.1 Piping Design and Installation

Figure 6.1

Note: On-site preparation required for all components except for the air conditioner.

For Inspection

Canvas Joint

Canvas Joint

Air outlet

Heat insulation layer

Heat insulation layer

Return

Air Inlet

•

Once the air conditioner body and the canvas joints are riveted together, the upper flange plate must be secured with screws.

(M6 x 12 screws are prepared on site.)

(1) In order to prevent short-circuit air delivery, the piping for air outlet and air return ducts must not be too close.

(2) The indoor unit does not have an air filter installed. The air filter must be installed at a location like an air inlet where it can be easily maintained.

(Without an air filter, dust particles may stick to the air heat exchanger which will make the air conditioner prone to failures and water leakage.)

(3) Before installing the air duct, ensure that the static pressure of the air duct is within the permitted range of the indoor unit (see section 6.2).

(4) Connect the canvas duct to the air return and air outlet ducts to prevent vibrations from the indoor unit transferring to the ceiling.

(5) Use heat insulation materials at a thickness of 25 mm or more to prevent condensation on the air duct.

(6) Connect the air duct as shown in Figure 6.1.

6.2 Fan Performance

7.1/8.0kW

200Pa

190Pa

180Pa

170Pa

160Pa

150Pa

140Pa

130Pa

120Pa

110Pa

100Pa(default)

90Pa

80Pa

70Pa

60Pa

50Pa

30Pa

0

20

40

60

80

100

120

140

160

180

200

0

5

3

1

0

0

3

1

0

5

2

1

0

0

2

1

0

5

1

1

St

a

ti

c

p

re

ssu

re

(P

a)

Air

flo

w (m

3

/h)

9.0kW

200Pa

190Pa

180Pa

170Pa

160Pa

150Pa

140Pa

130Pa

120Pa

110Pa

100Pa(default)

90Pa

80Pa

70Pa

60Pa

50Pa

30Pa

0

20

40

60

80

100

120

140

160

180

200

1130

1180

1230

1280

1330

1380

1430

St

a

tic

pr

ess

ur

e

(P

a)

Air

flo

w (m

3

/h)

Содержание Gama CND

Страница 2: ......