13

5

.

Install Connecting Pipes and Electronic Throttle

5

-

1

Requirements for the connecting length and drop height of the tubing of both

indoor and outdoor units

)

1 Please refer to the allowed length of tubing in the instruction of outdoor unit.

2

)

Please refer to the allowed drop height of tubing in the instruction of outdoor unit.

5

-

2

Material and Size of Tubing

5

-

3

Procedures for Connecting Pipes

Notice

Notice

!

During the installation process, keep the air, dust and other impurities from getting into the pipeline

system.

Fix indoor and outdoor units before installing the connecting pipe.

Keep dry while installing the connecting pipe and keep the water from getting into the pipeline system.

Connecting pipe must be wrapped by heat insulator. (Usually, the thickness is more than 10 mm, and it

is even thicker in closed humid area.)

5

-

3

-

1

Measure the needed length of connecting tubing, and make connecting tubing according to the

flowing methods. (For details, see the “Tubing Connection” column)

Connect the indoor unit before connecting the outdoor unit.

a

.

Pay attention to the configuration of winding tubing so as not to damage the tubing and its

insulation layer.

b

.

Smear the refrigerator oil (it must be engine oil which is compatible with the cooling medium of this

type) on the outside surface of flared joint and the conical surface of connecting nut and screw it 3 or 4

rounds with your hand (Fig. 5.1) before screwing the flared nut up.

c

.

Use two spanners at the same time when connecting or taking the tubing down.

d

.

The interface of indoor unit can't bear all the weight of the connecting tubing, because if the

interface is over-burdened, it will affect the cooling or heating effects of indoor unit.

2

)

The stop valve of outdoor unit should be completely shut down (as the default state when leaving the

factory). Unscrew the nut from the stop valve and connect the flared tube at once (within 5 minutes).

3

)

After connecting the refrigerant tubing to both indoor and outdoor units, eliminate the air according to

the column of “

”, then screw the nut up.

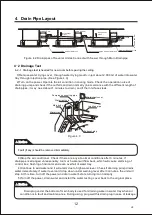

a

.

Notes for flexible coupling:

①

The winding angle should be less than 90°(Fig. 5.2).

②

Its sinuosity had better be in the centre of the pipe range, its bending radius should be more than

3.5 D (the diameter of pipeline)

.

③

Don't bend the flexible coupling pipe for more than 3 times.

Vacuum Supply

Smear refrigeration oil

Figure 5.1

Bend pipe with thumbs

Figure 5.2

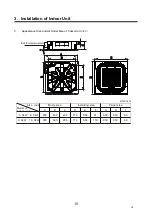

Table 5.1

Type

Type

Liquid pipes

(

mm

)

Liquid pipes

(

mm

)

Gas pipes

(

mm

)

Gas pipes

(

mm

)

3

.

2kW

~

5

.

6kW

2

.

2kW

~

2

.

8kW

7

.

1kW

~

8

.

0kW 9

.

0kW

~

16

.

0kW

φ

6

.

35

×

0

.

8

φ

9

.

52

×

0

.

8

φ

12

.

7

×

0

.

8

φ

9

.

52

×

0

.

8

φ

15

.

88

×

1

.

0

V.2

Содержание ECIN Series

Страница 52: ...Vis tanos en www easelectric es V 2...