13

For additional information email

or call 800-345-6007 M-F 8-5

Operator’s Manual

CRT Rototiller

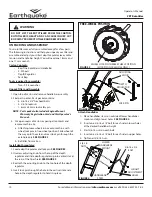

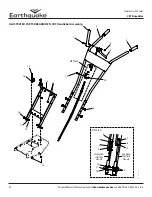

Wheel Lock Pins

To Place Wheels In Free-Wheel Position Do As Follows:

NOTE: This allows wheels to turn freely on the axle for

easy transportation.

1. Remove lock pin. Slide wheel inward toward machine.

SEE FIGURE 10

2. Insert lock pin through the axle hole only, fold lock ring

to secure pin to axle.

3. Repeat for other wheel.

To place wheels in tilling position do as follows:

NOTE: This locks wheels to the axle so they are able to

propel the machine forward while in use.

1. Remove lock pin. Slide wheel slightly outward away from

machine. Align hole in axle with hole in wheel hub.

SEE FIGURE 11

2. Insert lock pin through both holes, fold lock pin ring to

secure pin to axle.

3. Repeat for other wheel.

NOTE: Always have both wheel lock pins in or out. Do not

operate tiller with only one wheel locked.

WHEEL LOCK PIN IN TILLING POSITION

(LOCK PIN IN AXLE HOLE AND WHEEL HOLE)

13549-0012R1

TILLING POSITION

FIGURE 11

WHEEL LOCK PIN IN FREE-WHEEL POSITION

(LOCK PIN IN AXLE HOLE ONLY)

13549-0011R1

FREE-WHEEL POSITION

FIGURE 10

DO NOT START YOUR TILLER UNTIL YOU HAVE READ

THE MANUAL THAT CAME WITH YOUR ENGINE, AND

THE SECTIONS IN THIS MANUAL TITLED CONTROLS,

ADJUSTMENTS AND SAFETY. IF YOU HAVE READ

THESE, FOLLOW THE STEPS BELOW TO START

YOUR TILLER. ALWAYS PERFORM THIS PRE-START

INSPECTION BEFORE STARTING THE ENGINE. FAILURE

TO FOLLOW WARNINGS CAN CAUSE INJURY OR

DEATH.

NEVER START ENGINE OR OPERATE TILLER WITH

WHEELS IN FREE-WHEEL POSITION. ALWAYS SET THE

WHEELS IN TILLING POSITION BEFORE STARTING

ENGINE. THE FREE-WHEEL POSITION IS FOR

TRANSPORTING THE TILLER LONG DISTANCES OVER

LEVEL GROUND. DO NOT ATTEMPT TO MOVE THE

TILLER UP OR DOWN STEEP GRADES IN THE FREE-

WHEEL POSITION.

WARNING

OPERATION

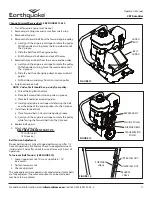

Pre-start inspection:

1. Make sure all safety guards are in place and all nuts and

bolts are secure.

2. Check oil level in engine crankcase. See your engine

manual for procedure and specifications.

3. Inspect air cleaner for cleanliness. See your engine

manual for procedure.

4. Check the fuel supply. Fill the fuel tank no closer than one

inch from top of tank to provide space for expansion. See

your engine manual for fuel recommendations.

5. Be sure spark plug wire is attached and spark plug is

tightened securely.

6. Check position of wheels.

7. Check depth regulator lever position.

8. Examine underneath and around engine for signs of oil or

fuel leaks.

9. Inspect fuel hoses for tightness and fuel seepage.

10. Look for signs of engine damage.

11. Remove excessive debris from muffler area and recoil

starter.

12. Turn fuel shutoff valve to the

ON

position if engine

is equipped with one. It’s located between tank and

carburetor.