Operator’s Manual

CRT Rototiller

4

For additional information email

or call 800-345-6007 M-F 8-5

GENERAL SAFETY RULES

•

Read, understand, and follow all instructions on the

machine and in the manual(s). Be thoroughly familiar

with the controls and the proper use of the machine

before starting.

•

Use this equipment for its intended purpose only.

•

Familiarize yourself with all of the safety and

operating decals on this equipment and on any of its

attachments or accessories.

•

Do not put hands or feet near or under rotating parts.

•

Only allow responsible individuals who are familiar

with the instructions to operate the machine. Do

not allow children to operate this machine. Do not

allow adults to operate the machine without proper

instruction.

•

Thoroughly inspect the area where the machine

is to be used and remove all foreign objects. Your

equipment can propel small objects at high speed

causing personal injury or property damage. Stay

away from breakable objects, such as house windows,

automobiles, greenhouses, etc.

•

Wear appropriate clothing such as a long-sleeved

shirt or jacket. Also wear long trousers or slacks. Do

not wear shorts. Never wear sandals, sneakers or

open shoes, and never operate the machine with bare

feet.

•

Do not wear loose clothing or jewelry. They can get

caught in moving parts. Always keep hands, feet, hair

and loose clothing away from any moving parts on

engine and machine.

•

Always wear safety goggles or safety glasses with side

shields when operating the machine to protect your

eyes from foreign objects which can be thrown from

the unit. Always wear a protective hearing device.

•

Always wear work gloves and sturdy footwear. Wear

footwear that will improve footing on slippery

surfaces. Leather work shoes or short boots work well

for most people. These will protect the operator’s

ankles and shins from small sticks, splinters, and other

debris.

•

It is advisable to wear protective headgear to prevent

the possibility of being struck by small flying particles,

or being struck by low hanging branches, twigs,

or other objects which may be unnoticed by the

operator.

•

Do not operate the machine without proper guards or

other safety protective devices in place.

•

See manufacturer’s instructions for proper operation

and installation of accessories. Only use accessories

approved by the manufacturer.

•

Operate only in daylight or good artificial light.

•

Do not operate product when fatigued or under the

influence of alcohol, drugs or other medication which

can cause drowsiness or affect your ability to operate

this machine safely.

•

Never operate machine in wet grass. Always be sure

of your footing; keep a firm hold on the handle and

walk; never run.

•

Watch for traffic when operating machine near, or

when crossing roads.

•

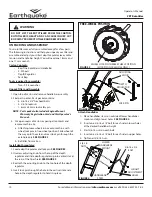

If the equipment should start to vibrate abnormally,

stop the engine (motor), flip the ON/OFF switch to the

OFF

position. Check immediately for cause. Vibration

is generally a warning of trouble. If the noise or

vibrations of the machine increase, stop immediately

and perform an inspection.

•

Never leave the machine unattended when the

engine is running. Flip the ON/OFF switch to the

OFF

position.

•

Regularly inspect the machine. Make sure parts are

not bent, damaged or loose.

•

Temperature of muffler and nearby areas may exceed

150° F (65° C). Allow muffler and engine areas to cool

before touching. Never pick up or carry the machine

while the engine is running.

•

Prolonged exposure to noise and vibration from gasoline

engine-powered equipment should be avoided. Take

intermittent breaks and/or wear ear protection from

engine noise as well as heavy work gloves to reduce

vibration in the hands.

•

Keep all screws, nuts and bolts tight.

•

Do not transport the machine from one place to

another with the engine running.

•

When moving the packaged machine, always do so

with a partner.

•

Check local regulations for age restrictions on use of

this machine.

Product-specific safety rules:

•

Do not till above underground utilities, including

water lines, gas lines, electric cables, or pipes. Do

not operate the machine on terrain/soil with large

rocks and foreign objects which can damage the

equipment.

•

After striking a foreign object, stop the engine. Flip

the ON/OFF switch to the OFF position. Inspect

the machine for damage. If damaged, repair before

starting and operating the machine.

•

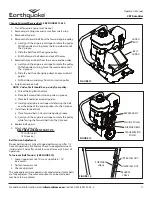

The tines of the tiller should not rotate when the drive

control lever is released into the neutral position. If

it does rotate when in neutral, contact Earthquake®

Customer Service for instruction.

•

If an object becomes lodged in the tines, flip the ON/

OFF switch to the OFF position, allow to cool before

attempting to remove the foreign object.

•

Pulleys and belts should be kept free of oil or other

moisture for efficient operation.

•

Disengage all clutches and leave control lever in the

neutral position before starting the engine.