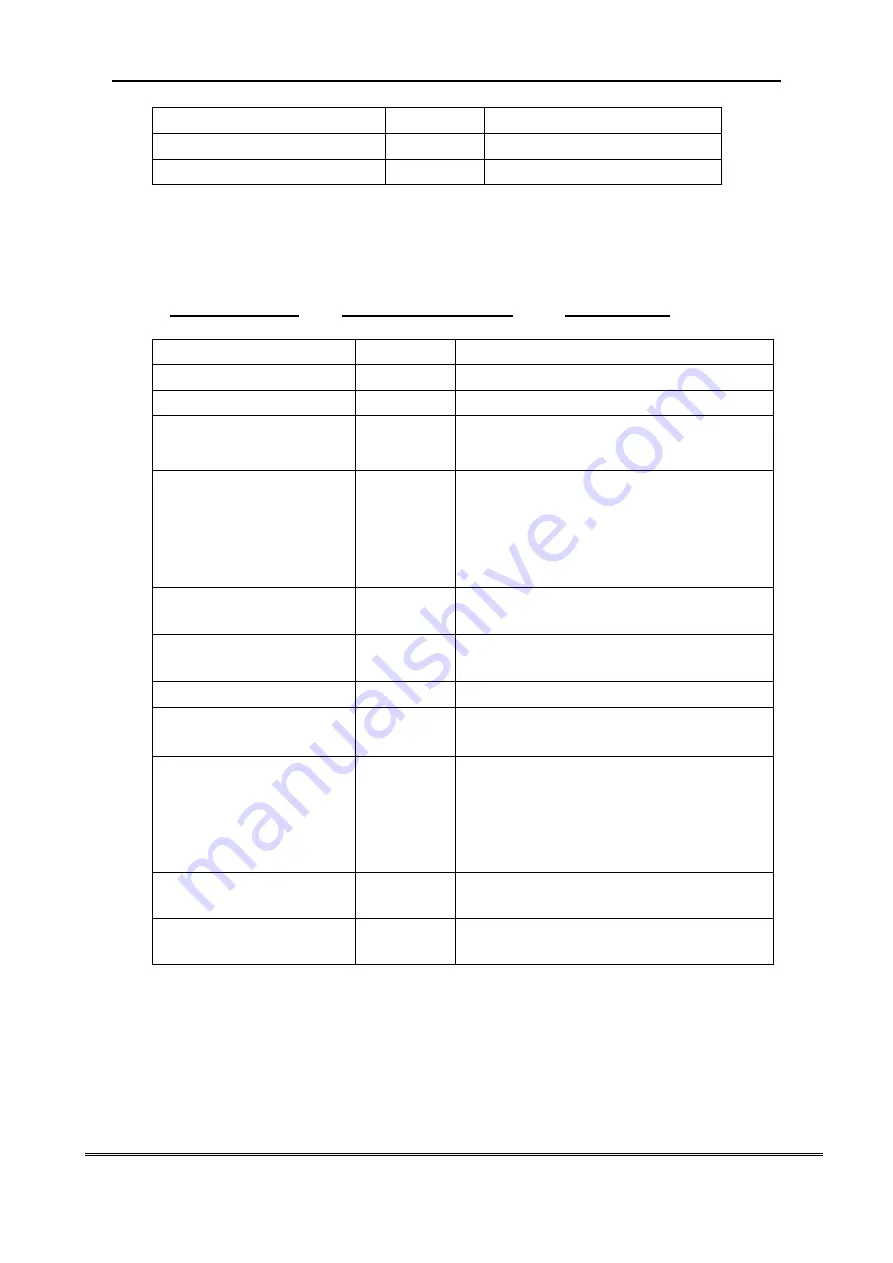

10. RETURN

OPERATION

DISPLAY

ILLUSTRATION

Press

【

MODE

】

key 9 times

〖

ESC

〗

press

【

ENTER

】

key

〖

0

〗

Return to normal testing status

11. SET POINT

There are two user programmable Set-Point can be used for safety and warning applications

or for limit weighing.

_

1 LO SP1 1 HI 2 LO SP2 2 HI

OPERATION

DISPLAY

ILLUSTRATION

Press

【

MODE

】

key twice

〖

SETUP

〗

Confirm, enter into parameter setting program

Press

【

ENTER

】

〖

SP1

〗

Set point 1

Press

【

ENTER

】

to confirm

〖

1 OFF

〗

New dynamometer, it display 1 OFF, if

parameter set, it display set value.

Press

【

ZERO

】

to choose

〖

1 HI

〗

or

〖

1 LO

〗

There are 3 choice,1 OFF means you don

’t

set point, 1 HI means the indicator will alarm

when load exceed the value you set, 1 LO

means the indicator will alarm when load

smaller than the value

Press

【

ENTER

】

to confirm

〖

02000

〗

New dynamometer it display 02000, if

parameter set, the screen display set value.

Press

【

ZERO

】

and

【

TARE

】

to change value

〖

01000

〗

Set “1 HI” or “1 LO” Value. e.g. 1000kg

Press

【

ENTER

】

to confirm

〖

SP2

〗

Set point 2

Press

【

ENTER

】

to confirm

〖

2 OFF

〗

New dynamometer, it display 2 OFF, if

parameter set, it display set value.

Press

【

ZERO

】

to

choose

〖

2 HI

〗

or

〖

2 LO

〗

There are 3 choice,2 OFF means you don

’t

set point, 2 HI means the indicator will alarm

when load exceed the value you set, 2 LO

means the indicator will alarm when load

smaller than the value

Press

【

ENTER

】

to confirm

〖

01200

〗

New dynamometer it display 01200, if

parameter set, the screen display set value.

Press

【

ZERO

】

and

【

TARE

】

to change value

〖

03000

〗

Set “2 LO” or “2

HI” Value. e.g.3000kg

If you needn

’t to set point, you only need to press

【

ENTER

】

until it display next function

〖

g=

〗

USER MANUAL 10