15

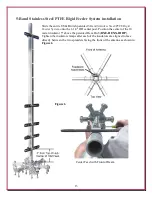

Installing the Center Post Rope Hub

Using

Figure 8

as a reference,

assemble the center post rope

connection hub assembly with

hardware.

Figure 8

Install center post rope connection hub assembly, 1-1/2" from the top of the center post as shown

in

Figure 9

. Orient this hub so its vertical holes are facing between every other spreader. Tighten

the hub hardware carefully so the center post and the hub are concentric (space between the center

post and the interior of the hub is even). When tightened to the center post, lock the hex head bolts

in place by tightening the 1/4-20 hex nuts against the hub. Install the 1-1/4" black vinyl cap on the

top of the center post.

Figure 9