26

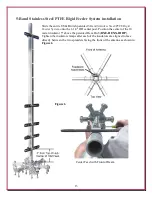

Final leveling and slight tension on the wires is accomplished by small, equal adjustments of the

wire guide stud clamp positions on the spreaders away from the center of the antenna. Too much

tension will distort the shape of the spreaders and slacken the other wire elements. This adjustment

process may take some time to get an acceptable balance between element tensions, but the goal is

to have all the wires horizontal, evenly spaced, with only slight tension to prevent antenna wires

from moving toward and away from each other in gentle breezes. The unique feature of the

“floating wire guides” will allow all of the spreaders and wires to move independently in strong

winds without causing undue stress, and then return to their natural position.

Remember, having tight wires will not improve performance - only appearance. A little slack is

better than too tight. This will eliminate stretching of the element wires and unnecessary tension on

the wire element ring terminals.

Perform final tightening of all spreader clamps, wire guide and rope attachment p-clamp hardware

and stud clamps. DO NOT over tighten these stainless steel element clamps. A modest tightening of

these small gear screws will accomplish sufficient hold.

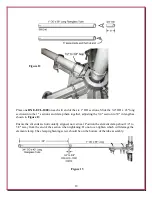

If the optional Feedline Current Choke was not installed, connect a coaxial cable (RG-213 or

equivalent) feedline to the included double female SO-239 (UHF to UHF) adapter installed at the

end of the pigtail. If the optional Feedline Current Choke is installed, connect your coaxial cable

feedline (RG-213 or equivalent) to the bottom of the Feedline Current Choke. Use electrical tape to

hold the coaxial cable to the center post and to an extended mast, if used, above the rotator. Route

the coaxial cable around the rotator with the appropriate loop, as shown in the image on page 27,

using tape to secure the coaxial cable to the mast.

Installation on a Mast and

Rotator

The aluminum tube that holds the Fiberglass

Center Post is supplied with the Hexxagonal

Beam. This tube has an outside diameter of 1-

3/8" and may be used directly into a rotator.

When mounting the completed Hexxagonal

Beam on the customer supplied mast, use mast

or tubing that has an inside diameter of 1-3/8".

This mast could be 3 feet or 6 feet long

depending on your rotator specifications. When

using DX Engineering tubing, use two pieces

of .058" wall thickness tubes that are 1-1/2"

OD and 1-5/8" OD and nested together to give

you a thick wall mast that the 1-3/8" tube will

fit in.

Once mounted, the mast should be held to the Hexxagonal Beam tube by drilling one or two holes

and pinning as shown in the picture.