Printed in U.S.A. 6/22

FR# 712182-00 Rev. 6

©Copyright 2022 Dwyer Instruments, Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: [email protected]

6.1 PRESSURE CALIBRATION (Continued)

Span Adjustment is used for calibration of the internal or external pressure transducer

sensors and testing operation of hardware circuitry. Calibration should only be

performed by qualified personnel, using a pressure calibrator.

1. Select the sensor (DP, UI2, UI3) desired for recalibration. The indicated pressure

will be shown.

2. Disconnect the two pressure tubes from the unit.

3. Connect tubing from the calibrator to the “-” LOW and “+” HIGH ports identified on

the back of the RSMC unit.

4. Apply full range pressure. For example ±0.5 in w.c. range use +0.5 in w.c. pressure.

5. When pressure reaches full range, press Span Adjustment.

6. The output at full range must be within 10% of the factory calibration to allow

readjustment.

Selecting Reset permits the user to discard any changes that may have been done

unintentionally, leaving the unit as it was before any Zero Adjustments or Span

Adjustment modifications.

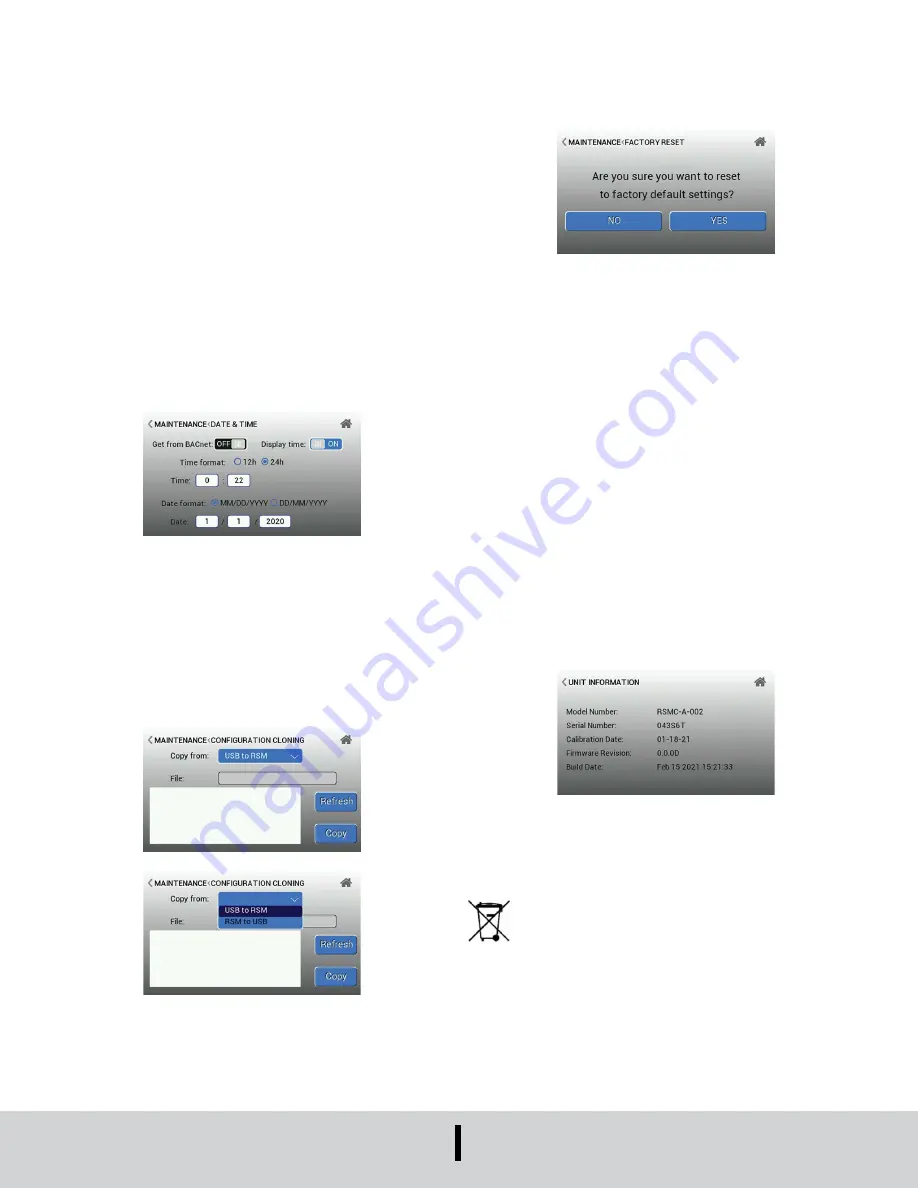

6.2 DATE AND TIME

The Date and Time allows the unit date and time to be manually set, or sourced via

BACnet. The display of the date and time on the home screen can be customized.

Since there is no internal battery, if the power is lost, the date and time will be erased.

If the device is connected by Modbus

®

or BACnet, the values will be restored via the

network. To access Date and Time from the home screen, press the Settings icon in

the top right corner. From the Maintenance menu, select Date and Time.

6.3 DUPLICATE CLONING

To access Duplicate Cloning from the home screen, press the Settings icon in the

top right corner. From the Maintenance menu, select Duplicate Cloning. The Copy

to USB function is used to capture a RSMC configuration onto a USB thumb drive.

This function is useful to store configurations on a personal computer, where a

controlled inventory of one or more units can be maintained. In the event that a RSMC

password has to be reset or the unit needs replacement, the proper configuration file

can be retrieved and loaded. The Copy from USB function is used to copy a RSMC

configuration from a USB thumb drive to another RSMC unit. A RSMC configuration

previously captured can then be “cloned,” or copied to other units to reduce setup time.

Once copied, the “cloned” unit then only needs room-specific parameters setup, such

as room name, IP address, and other unique parameters.

6.4 RESET TO FACTORY DEFAULTS

The function Reset to Factory Default is used in the event a RSMC unit must be put

into a known state for either service or a configuration reload. To access Reset rom the

home screen, press the Settings icon in the top right corner. From the Maintenance

menu, select Reset.

A factory reset may help establish a baseline of original functionality from which to

build the specific configuration for a given application. New configurations can then

be added by either touchscreen entry, Copy from USB, or over the BACnet network.

Selecting NO will cause the RSMC unit to remain in its current state of configuration.

Selecting YES will cause the RSMC to erase all configuration information and restore

the RSMC to its original factory configuration. Once YES is selected, this function

cannot be reversed or undone.

An alternative way to reset the unit to factory default settings is to insert a paperclip

and press and hold the button located on the back of unit above terminal block pins

4 and 5. The connector for the second terminal block may need to be removed for

easier access. Resetting with the button on the back of the unit will also clear all

passwords established. This resetting method should only be used if the password(s)

are forgotten or lost.

6.5 FIRMWARE UPDATE

To update the device firmware, a USB-C to USB-A drive will be required. Download

the updated device firmware onto the USB drive via a laptop or desktop computer. Do

not change the name of the firmware file, it will end in “.kld”. Once the firmware file

is on the USB-C to USB-A drive, insert the USB-C connection into the back side of

the RSMC unit while it’s powered off. Power on the RSMC with 24 VAC/DC with the

USB drive plugged in. Wait for the device to power on completely. The firmware will be

updated automatically. Once the device has successfully powered on and shows the

homescreen, power off the device and remove the USB drive from the RSMC.

6.6 UNIT INFORMATION

The Unit Information menu displays the model number, serial number, calibration date,

and firmware version. To access the unit information menu, press the Settings icon in

the top right corner of the home screen and select the ‘Unit Information’ button.

MAINTENANCE/REPAIR

Upon final installation of the Series RSMC, no routine maintenance is required.

The Series RSMC is not field serviceable and is not possible to repair the unit.

Field repair should not be attempted and may void warranty. Do not dispose of as

unsorted domestic or municipal waste. Consult retailer or local authorities for recycling

information.

WARRANTY/RETURN

Refer to “Terms and Conditions of Sale” in our catalog and on our website. Contact

customer service to receive a Return Materials Authorization number before shipping

the product back for repair. Be sure to include a brief description of the problem plus

any additional application notes.

Modbus

®

is a registered trademark of Schneider Electric USA, Inc.

This symbol indicates waste electrical products should not be disposed

of with household waste. Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice.