5

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

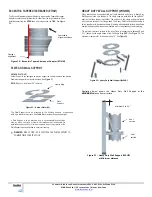

SECTION C - PIPE & FITTING JOINT ASSEMBLY

The ends of each inner pipe are made of flanges. All the joints between sections are

flange-to-flange of the inner pipe.

CAUTION: SHARP SHEET METAL, RISK OF CUTS WITH SLEEVES AND

SECTIONS.

All sections have an unattached alignment sleeve (See figure 5).

The alignment sleeve facilitates alignment of adjacent sections and

provides a backing for the sealant applied to flange face keeping it in the intended

location. It may either be placed on the outlet end section or in the

downstream section. It is not a required part, which means that it might not be used

at all.

Figure 5 – Feature Alignment Sleeve

SEALANT USAGE

Part No. S-650 –

(Permatex® Red High Temp Silicone) is red and is

one of our UL approved sealants for temperatures up to 650°F. Can

be used for V-Channel Bands and for weathering/sealing where

necessary.

Part No. S-2000 –

A high temperature pre-mixed sealant for flue gas

temperature up to 2000°F. S-2000 is water soluble and should not be

used where exposed to weather

Part No. S-375 –

(Nuflex 302 General Purpose) is a low temperature

grey silicone (450°F) only for weathering/sealing on outdoor seams

and Outer Band (BSE) where necessary.

STEP 1

Apply a continuous bead of S-650 or S-2000 sealant in the V-Clamp

grove of the locking band.

NOTE: Sealant is supplied by DuraVent

- individual tubes are marked

S-650

or

S-2000

. See

TABLE 6

for number of tubes per joint.

CAUTION: THE USE OF ANY OTHER SEALANT IS NOT RECOMMENDED, MAY VOID

CERTIFICATION AND MAY IMPAIR THE SEALING EFFECTIVENESS.

Figure

6

‐

Joint

Assembly

Step

1

STEP 2

Apply a continuous bead of S-650 or S-2000 sealant ¼” wide to one

of the flanges to be joined.

Figure

7

–

Joint

Assembly

Step

2

STEP 3

Join the two flanged ends of the duct section together and rotate

slightly to ensure complete coverage of sealant on flanges

Figure 8 – Joint Assembly Step 3

STEP 4

Install the V-Band around the flanges making sure the flanges are

located within the V-clamp

NOTE

: Do not locate V-Band hardware at the bottom side of the

horizontal duct joints

NOTE 1

: Light tapping with a hammer all around the band while

tightening bolts helps align and pull flanges together

Figure 9 – Joint Assembly Step 4

Removable

Alignment

sleeve