4

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

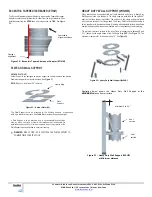

TABLE 4

Maximum Vertical Spacing between ANY Guide / Supports and

Maximum Freestanding above the Roof

MODEL

DCL

DAS1 / DIS1

DIS2

DIS4

HEIGHT (ft)

HEIGHT (ft)

HEIGHT (ft)

HEIGHT (ft)

Flue

Diameter

Ø

(in)

MVS* H* MVS* H* MVS* H* MVS* H*

5

20

8' 6"

20

7' 3"

20

6' 6"

20

5' 9"

6

20

9' 6"

20

8' 3"

20

7' 6"

20

6' 9"

7

20 10' 20 8'

9" 20 8'

3" 20 7'

8

20

10' 9"

20

9'

20

8' 6"

20

7' 3"

9

20 11'

6" 20 9'

3" 20 8'

9" 20 7'

6"

10

20 12' 20 9'

6" 20 9' 20 7'

9"

11 20 12'

6"

20 9'9" 20 9'

3" 20 8'

12 20 13' 20 10' 20 9'

6" 20 8'

3"

13

20

13' 6"

20

10' 3"

20

9' 9"

20

8' 6"

14

20 14' 20 10'

6" 20 10' 20

9'

16

20

14' 6"

20

11'

20

10' 6"

20

9' 6"

18

20 15' 20 11'

6" 20 11' 20 10'

20 20 15' 20 12' 20

11'

6"

20

10'

9"

22

20 15' 20 12'

3" 20 11'

9" 20 11'

24

20 15' 20 12'

9" 20 12'

3" 20 11'

6"

26 20 15' 20 13' 20

12'

6"

20 12'

28

20 15' 20 13'

6" 20 13' 20 12'

3"

30

20 15' 20 13'

9" 20 13'

6" 20 12'

9"

32

20 15' 20 14'

3" 20 13'

9" 20 13'

3"

34

20 15' 20 14'

6" 20 14'

3" 20 13'

6"

36 20 15' 20 15' 20

14'

6"

20

13'

9"

MVS*

Maximum Vertical Spacing between two (2) Guides or

Support

and Guide in a Vertical Position

H**

Maximum Freestanding Height above the roof.

This limited height is due to wind loads.

Dimensions are in inches (diameter) and feet (distance)

TABLE

5

–

maximum

Horizontal

Spacing

between

each

Guide

/

Support

Product

Flue

Diameter

Ø

(in)

Distance

(ft)

DCL

DAS1

DIS1

DIS2

DIS4

Half

Angle

Ring

(HAR)

/

Full

Angle

Ring

(FAR)

/

Anchor

Support

(AP)

/

Anchor

Plate

with

Length

(APL)

/

Heavy

Duty

Wall

Guide

(HDWG)

5

to

12

23

23

19

16

12

14

to

24

19

19

16

14

10

26

to

36

15

15

13

11

8

Dimensions are in inches (diameter) and feet (distance)

EXTERIOR CORROSION PROTECTION

It is recommended to apply an exterior grade high heat paint to any

plate supports, full/half angle rings, wall guides, aluminized outer

walls for corrosion protection against the elements.

EX: Rust-Oleum V200 series High Heat Industrial Aerosol

SEISMIC REQUIREMENTS

In certain areas of the country, local codes contain requirements to

address seismic risks. Seismic requirements for chimneys and

grease ducts usually include specifications for additional “sway bars” /

bracing, or similar devices in order to help stabilize the system in the

event of an earthquake.

Specific guidelines (including spacing, location, size and method of

attachment of bracing / sway bars or other devices for addressing

seismic requirements vary depending upon the adopted code,

seismic zone, duct size, location in building, etc. and are not within

the scope of this document.

Consult with a design professional in order to determine compliance

options for these potentially complex requirements when this product

is to be installed in a building where these additional requirements

apply.

The support methods described in this document have been proven

adequate (via UL certification) for locations where there are no

additional seismic zone requirements. In order to address additional

seismic requirements they may be further supplemented with a

variety of generic sway bars or braces that attach to or around the

outer wall of the chimney / grease duct system. Full Angle Rings

(FAR) and Half Angle Rings (HAR) may be included as components

of such supplemental bracing.