www.duralloy.net.au

|

1300 369 456

11

171

& 191

MULTIMIG

OWNER’S MANUAL

2. Wire Feed Speed

. Increase in wire feed speed increases

weld current, Decrease in wire feed speed decreases weld

current

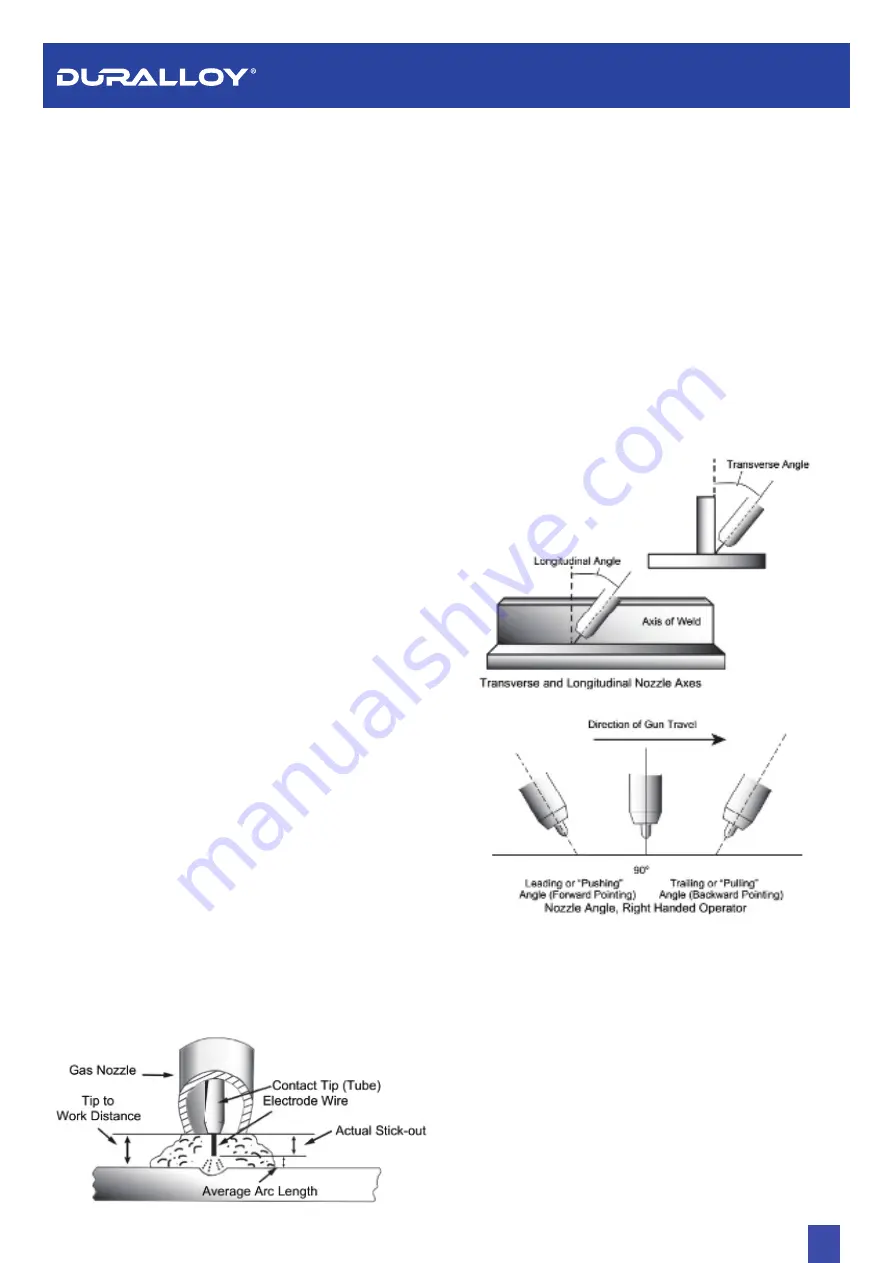

3. Nozzle Angle

. This refers to the position of the welding gun

in relation to the joint. The transverse angle is usually one

half the included angle between plates forming the joint. The

longitudinal angle is the angle between the Centre line of the

welding gun and a line perpendicular to the axis of the weld.

The longitudinal angle is generally called the Nozzle

Angle and can be either trailing (pulling) or leading

(Pushing). Whether the operator is left handed or right

handed has to be considered to realize the effects of each

angle in relation to the direction of travel.

The electrode wire stick out from the MIG Torch nozzle should be

between 10mm to 20.0mm. This distance may vary depending on

the type of joint that is being welded

Travel Speed

•

The speed at which the molten pool travels influences the

width of the weld and penetration of the welding run

MIG Welding (GMAW) Variables

•

Most of the welding done by all processes is on

carbon steel. The items below describe the welding.

•

Variables in short-arc welding of 24gauge (0.024”, 0.6mm) to

¼” (6.4mm) mild sheet or plate. The applied techniques and

end results in the GMAW process are controlled by these

variables.

Preselected Variables

•

Preselected variables depend upon the type of material

being welded, the thickness of the material, the welding

position, the deposition rate and the mechanical properties.

These variables are:

•

Type of electrode wire

•

Size of electrode wire

•

Type of gas (not applicable to self-shielding wires FCAW)

•

Gas flow rate (not applicable to self-shielding wires FCAW)

Primary Adjustable Variables

•

These control the process after preselected variables have

been found. They control the penetration, bead width, bead

height, arc stability, deposition rate and weld soundness.

They are:

•

Arc Voltage

•

Welding current (wire feed speed)

•

Travel speed

Secondary Adjustable Variables

These variables cause changes in primary adjustable variables

which in turn cause the desired change in the bead formation.

They are:

1.

Stick-out

(distance between the end of the contact tube (tip)

and the end of the electrode wire). Maintain at about 10mm

stick-out

DISTANCE FROM THE MIG TORCH NOZZLE TO THE WORK PIECE

ESTABLISHING THE ARC AND MAKING WELD BEADS

Before attempting to weld on a finished piece of work, it is

recommended that practice welds be made on a sample metal of

the same material as that of the finished piece

The easiest welding procedure for the beginner to experiment

with MIG welding is the flat position. The equipment is capable of

flat, vertical and overhead positions.

For practicing MIG welding, secure some pieces of 16 or 18

gauge (0.06” 1.5mm or 0.08” 2.0mm) mild steel plate 6” x 6” (150

x 150mm). Use 0.030” (0.8mm) flux cored gasless wire or a solid

wire with shielding gas

Содержание 171 MULTIMIG

Страница 1: ...171 191 MULTIMIG OWNER S MANUAL www duralloy net au 1300 369 456...

Страница 18: ...www duralloy net au 1300 369 456 18 171 191 MULTIMIG OWNER S MANUAL 11 3 Wire feeder 11 4 Cables...

Страница 19: ...www duralloy net au 1300 369 456 19 171 191 MULTIMIG OWNER S MANUAL CONNECTION DIAGRAM OF THE MACHINE...

Страница 20: ...www duralloy net au 1300 369 456 20 171 191 MULTIMIG OWNER S MANUAL EXPLODED DRAWING...

Страница 22: ...www duralloy net au 1300 369 456...