DUPLOMATIC E.M.DDC4-400V/RK RELEASE 1.9 07-09

EM DDC4-400-RK-0709gb.doc

18

EXTENDED ALARM DESCRIPTION/TROUBLESHOOTING

In case an alarm is present on ALBITxx signals, the ALPOSxx signals give the sub-group code to better identify

the cause of the problem.

The I/O board is provided by LED to give the status of each output.

ALARM Description

1.0

Fault in resolver supply:

-short on resolver line.

If, after the short removal, the alarm persist, replace the controller.

1.1

Fault in three phase supply when the motor is enabled:

- check the 400 V supply.

If the voltage is OK and the alarm persist, replace the controller.

1.2,1.3,

1.4,1.6

Fault on internal auxiliary supply.

If the alarm persist, replace the controller

1.5

Fault on internal 24 V supply to switches:

-short on switches cable or defective switch.

If the alarm persist, replace the controller

2.0

Overvoltage on three-phase line:

-if random, ensure that three phase supply is under specification and in case provide additional stabilizers

If the alarm persist, replace the controller

2.1

Overvoltage reached during dynamic braking:

-the inertia loaded on disc is too high: try to reduce the inertia.

If the alarm persist, replace the controller.

3.0

Motor Overcurrent.

-short between servomotor wires

-short between servomotor wire and ground

-wrong resolver connection.

-poor resolver cable shielding.

To avoid thermal overload on power bridge due to repeated alarms, it is necessary to switch off the controller to clear the

alarm.

3.1

Motor Overload.

-inertia loaded on disc exceeds limits (check that the turret is set to the right inertia value by the PTAB03 signal - LK3 on

connection box);

-the unbalanced load exceeds limits;

-crash during disc rotation;

-zero switch or zero cam are not well positioned (if the alarm happen when the turret is locking at the reference cycle

completion);

-wiring to the motor or to the resolver is defective.

-mechanical hardening

3.2

Position controller error exceeds limits:

-inertia loaded on disc exceeds limits (check that the turret is set to the right inertia value by the PTAB03 signal - LK3 on

connection box);

-the unbalanced load exceeds limits;

-the tool touch the piece slowly during disc rotation;

-the wiring to the resolver is defective.

-mechanical hardening

3.3

The time limit to execute the cycle has been reached:

-the tool touch the piece slowly at the end of the cycle so cannot reach the final position;

3.4

The reference cam is out of the expected position (after the reference cycle have been performed)

-reference switch is damaged or out of position

-reference cam is damaged or out of position.

-mechanical damage

3.5

The thermal detector of the motor :

-indexing frequency too high;

-defective motor;

-the thermal detector is not connected.

-wiring

3.6

Resolver fault.

-wrong wiring

-resolver excitation is off.

3.7

Ambient temperature on controller side too high.

3.8

Heatsink temperature too high.

3.11

General cycle timeout.

A problem not covered by other alarms has occurred.

4.0

The signal of the locking switch stays on during the unlocking phase:

-unlocking pressure too low;

-bad position of locking switch;

-bad switch connection/wiring (remote application mainly);

-the locking switch is defective.

Содержание DDC4-10-400/20

Страница 24: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 24 SERVOMOTOR CABLE ...

Страница 25: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 25 DRIVER SUPPLY ...

Страница 26: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 26 RESOLVER SWITCHES CABLE ...

Страница 27: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 27 ...

Страница 28: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 28 ...

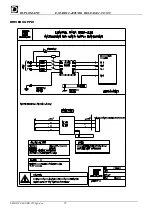

Страница 29: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 29 DIGITAL INPUT AND OUTPUT ...

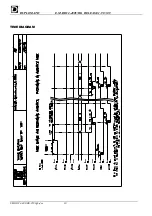

Страница 30: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 30 TIME DIAGRAM ...

Страница 31: ...DUPLOMATIC E M DDC4 400V RK RELEASE 1 9 07 09 EM DDC4 400 RK 0709gb doc 31 SERVICE SERIAL CONNECTION ...