32

ObservAir

Operating Manual

1.

Determine BC

avg

and logging interval

: Both of these parameters

depend on the sensor application and must be determined by the user.

The average BC concentration (BC

avg

) during the campaign can be

estimated by (1) searching the literature or regulatory databases for

representative BC concentration data, or (2) conducting preliminary

testing with the ObservAir at a flow rate setting of 100 ccm.

The logging

interval is dictated by the application context and goals. For example,

long-term ambient monitoring may only require hourly measurements,

while mobile platforms require rapid data logging every 10 seconds or

less. In both cases, these parameters may simply be estimated to set

the sensor flow rate initially, and adjusted thereafter depending on the

results. As an example, we will choose values of 0.4 ug/m

3

and 1 hour

to illustrate each step in this procedure.

2.

Calculate requisite BC measurement resolution:

As a rule of thumb,

the baseline noise at the desired logging interval should be < 10% of

the expected BC concentration. So for our example, baseline noise

should be < 0.1*0.4 = 0.04

µ

g/m

3

on an hourly basis.

3.

Calculate the minimum allowable flow rate:

From Table 4, find the BC

baseline noise at the requisite timebase (2 sec, 15 sec, 1 min, or 1 hour).

Since this noise specification is for a flow rate setting of 100 ccm, the

minimum required flow rate can be estimated using the equation

below. For our example, Table 4 shows that the baseline BC noise at 1

hour is 0.01

µ

g/m

3

, so the minimum flow rate is (0.01/0.04)*100 = 25

ccm. Note that the results of this calculation are bounded by the

ObservAir’s minimum and maximum flow rate settings: 25 and 200

ccm respectively.

𝐹𝑅

.%/

=

𝑁𝑜𝑖𝑠𝑒

$0"1

𝑁𝑜𝑖𝑠𝑒

!"2

× 100ccm (6)

FR

min

= Minimum allowable flow rate (ccm)

Noise

spec

= Baseline specification from Table 3 (

µ

g/m

3

)

Noise

req

= Maximum BC noise calculated in Step 2 (

µ

g/m

3

)

4.

Calculate the maximum filter life:

Using the average BC concentration

from Step 1 and minimum flow rate setting from Step 3, calculate the

filter life according to the equation provided in Section 4.1. In our

example, the maximum filter life is 313.5/(25*0.4) = ~31 days.

5.

Optimize the flow rate to meet your needs:

Given these limiting values,

the flow rate setting can be optimized to meet your needs. For example,

if greater BC measurement resolution is desired at the expense of filter

life, the flow rate can be increased past the minimum value. Conversely,

flow rate may be reduced to achieve the opposite result.

33

ObservAir

®

Operating Manual

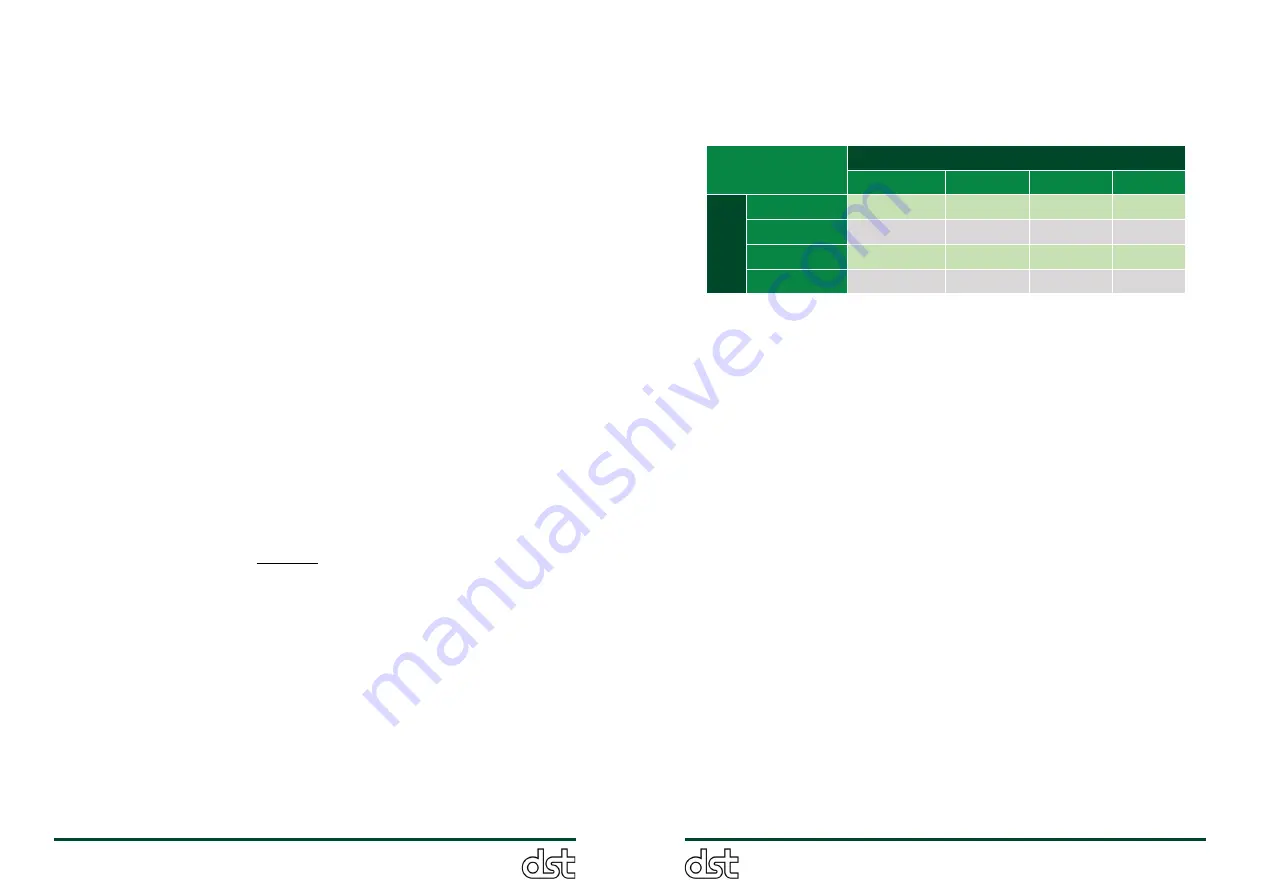

For reference, Table 7 shows the ObservAir’s minimum flow rate

setting and maximum filter life as a function of average BC concentration

and data logging period. The values in the table are calculated according

the procedure presented above. Two illustrative scenarios are also provided.

Data logging period

2 sec

15 sec

1 min

1 hour

Av

g

.

BC

0.5

µ

g/m

3

N/A

200/3.1

100/6.3

25/25.0

1

µ

g/m

3

200*/1.6ª

100/3.1

50/6.3

25/12.5

5

µ

g/m

3

60/1.0

25/2.5

25/2.5

25/2.5

10

µ

g/m

3

30/1.0

25/1.3

25/1.3

25/1.3

Minimum Flow Rate (ccm)*/ Maximum filter life (days)ª

Table 8.

ObservAir’s minimum flow rate setting and maximum filter life as

a function of average BC concentration and data logging period. The

ObservAir cannot provide BC concentration data with a baseline noise <

0.05

µ

g/m

3

on 2-second basis, so the top left cell is empty.

•

Scenario 1:

BC

avg

= 7 ug/m

3

, Logging interval = 2 seconds

For this scenario, the BC baseline noise should be

≤

0.7

µ

g/m

3

at 2-second

logging. Using the calculation procedure above, the minimum flow rate

setting is (0.3/0.7)*100 = 43 ccm. For these settings, the maximum filter

life is ~1 day. Alternatively, refer to Table 8 and see that for 2-second

measurements of 5

µ

g/m

3

average concentrations, the flow rate setting is

60 ccm. By interpolation, the flow rate can be set to 60*7/5 = 43 ccm.

•

Scenario 2:

BC

avg

= 0.35 ug/m

3

, Logging interval = 1 minute

The BC baseline noise should be from

≤

0.035

µ

g/m

3

at 1-minute logging.

From Table 1, the noise is 0.05 ug/m

3

at 1-minute and 100 ccm, so the

minimum flow rate is (0.035/0.05)*100 = 70 ccm. In Table 8, a flow rate

of 100 ccm is recommended for 1-minute measurements at 5

µ

g/m

3

. By

interpolation, the flow rate can be set to 100*0.35/0.5 = 70 ccm. The filter

life can be calculated as 313.5/(0.35*70) = 12.8 days.

IMPORTANT NOTE:

The above considerations do NOT apply to gas

sensing. The gas sensors’ measurement performance remains largely

constant with flow rate. Only the gas sensors’ time response is affected by

flow rate, simply because of the residence time of sample air through the

sensor’s closed volume naturally varies. At higher flow rates, the residence

time diminishes and the gas cells respond more rapidly.