5

•

Only operate unit in good daylight. Do not

operate unit at night or in dark areas where your

vision may be impaired.

•

If situations occur which are not covered by this

manual, use care and good judgment. Contact

your dealer for assistance.

CHILDREN

•

Tragic accidents can occur if the operator is not alert to the presence of small children.

•

Keep children out of the work area and under the watchful eye of a

responsible adult other than the operator.

•

Be alert and turn the unit off if a child enters the area.

•

Never allow children under the age of 16 to operate the chipper.

REPAIR AND MAINTENANCE SAFETY

•

Use extreme care in handling gasoline and other

fuels. They are extremely flammable and the

vapors are explosive.

•

Store fuel and oil in approved containers, away

from heat and open flame, and out of the reach

of children. Check and add fuel before starting

the engine. Never remove gas cap or add fuel

while the engine is running. Allow engine to cool

at least two minutes before refueling.

•

Replace gasoline cap securely and wipe off any

spilled gasoline before starting the engine as it

may cause a fire or explosion. Extinguish all

cigarettes, cigars, pipes and other sources of

ignition.

•

Never refuel unit indoors because flammable

vapors will accumulate in the area.

•

Never store the machine or fuel container inside

where there is an open flame or spark, such as a

gas hot water heater, space heater, clothes dryer

or furnace.

•

To reduce fire hazard, keep engine and muffler

free of debris build-up. Clean up fuel and oil

spillage. Allow unit to cool at least five minutes

before storing.

•

Before cleaning, repairing, or inspecting, make

certain the flywheel and all moving parts have

stopped. Disconnect

both

spark plug wires and

keep them away from the spark plugs to prevent

accidental starting. Do not use flammable

solutions to clean air filter.

•

Check the blade and engine mounting screws at

frequent intervals for proper tightness. Also

visually inspect blade for wear or damage.

Replace the blades with parts which meet

original equipment specifications.

•

Knives should be checked for sharpness and the

nuts and bolts attaching them to the flywheel for

tightness every 8-10 hours of operation.

•

Never tamper with safety devices. Check their

proper operation regularly.

•

Never run this machine in an enclosed area as

the exhaust from the engine contains carbon

monoxide, which is an odorless, tasteless, and

deadly poisonous gas.

•

Never operate your chipper in poor mechanical

condition or when in need of repair. Periodically

check and keep all nuts, bolts, and screws tight

to be sure the equipment is in safe working

condition. Be sure all safety guards and shields

are in proper position. These safety devices are

for your protection.

•

Inspect the belt each time you use the unit. Look

for damage, worn areas or tears. Do not use the

unit if this condition exists.

•

If your machine strikes any foreign object or

starts making an unusual noise or vibration,

immediately shut off engine, disconnect spark

plug wire from spark plug, and allow all moving

parts to come to a complete stop. Inspect for

damage and repair and or replace damaged

parts. Check for and tighten any loose parts.

•

Do not tamper with the engine’s governor setting.

The governor controls the maximum safe

operation speed and protects the engine. Over-

speeding the engine is dangerous and will cause

damage to the engine and to the other moving

parts of the machine. See your authorized dealer

for engine governor adjustments.

BEFORE STARTING ENGINE, ALWAYS CHECK OIL LEVEL!

Содержание 18.0 HP

Страница 2: ...2...

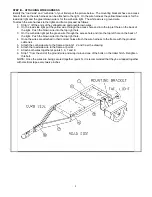

Страница 18: ...18 PARTS BREAKDOWN C182 CHP CHIPPER...

Страница 20: ...20 PARTS BREAKDOWN 913 0215 CHIPPER BASIC MACHINE...