7

Air Coil Nailer MCN70

www.aeroprotools.com

OPERATING INSTRUCTIONS

4.1 Preparing a tool for first time operation

Please Read and observe these Operating Instruction before using the tool. Basic safety measures should

always be strictly followed to protect against damage to the equipment and personal injury to the user or

other people working in the vicinity of operation.

4.2 Connection to the compressed air system

Ensure that the pressure supplied by the compressed air system does not exceed the maximum allowable

pressure of the fastener driving tool. Set the air pressure initially to the lower value of the recommended

allowable pressure (see TECHNICAL DATA).

Empty the magazine to prevent a fastener from being ejected at the next stage of work in the event that

internal parts of the fastener driving tool are not in the starting position following maintenance and repair work

or transportation.

Connect the fastener driving tool to the compressed air supply using suitable pressure hose equipped with

quick-action connectors.

Check for proper functioning by applying the muzzle of the fastener driving tool to a piece of wood or wooden

material and actuating the trigger once or twice.

4.3Filling the magazine

Only those fasteners specified under TECHNICAL DATA (see 1.1) may be used

When filling the magazine, hold the tool so that the muzzle is not pointing towards the operator or any other

person or animals.

4.4 Handling the tool

Pay attention to

2-Special Reference-

of these operating instructions.

Having checked that the fastener driving tool is functioning correctly, apply the tool to a work piece and

actuate the trigger.

Check whether the fastener has been driven into the work piece in accordance with the requirements.

- if the fastener is protruding, increase the air pressure in increments of 0.6 bar, checking the result

after each new adjustment;

- if the fastener is driven into an excessive depth reduce the air pressure I increments of 0.6 bar until

the result is satisfactory.

You should endeavor in any event to work with the lowest possible air pressure. This will give you three

significant advantages;

1.energy will be saved,

2.less noise will be produced,

3.a reduction in fastener driving tool wear will be achieved.

Avoid triggering the fastener driving tool if the magazine is empty.

Any defective or improperly functioning fastener driving tool must immediately be disconnected from the

compressed air supply and passed to a specialist for inspection.

In the event of longer breaks in work or at the end of the working shift, disconnect the tool from the

compressed air supply and it is recommended to empty the magazine.

The compressed air connectors of the fastener driving tool and the hoses should be protected against

contamination, the ingress of coarse dust chips, sand etc, will result in leaks and damage to the fastener

driving tool and the couplings.

Содержание PCN70

Страница 1: ...MANUAL PCN70...

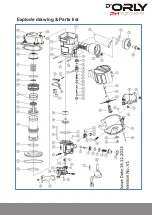

Страница 11: ...10 Air Coil Nailer MCN70 www aeroprotools com Explode drawing Parts list...