82

COLD WEATHER OPERATION

9/275, 9/305, 12/250, 17/240, 21/220

COLD WEATHER

It is possible to operate engines in extremely cold environments if they

are properly prepared and maintained.

Satisfactory performance of an engine in low ambient temperature

conditions requires modification of the engine, surrounding equip-

ment, operating practices and maintenance procedures.

The correct engine coolant lubricating oil and fuels

must

be used for

the cold weather range in which the engine is being operated. Below

are the recommendations for these critical engine fluids:

Ambient Temperature

0 to -32°C (32 to -25°F)

Use 50-percent ethylene glycol antifreeze and 50-percent water for the

engine coolant mixture.

Refer to Lubricating Oil recommendations and Specifications and

Coolant Recommendations and Specifications in the Fuels, Lubricants

and Coolants Section for the correct specifications.

The Diesel fuel

must

have maximum cloud and pour points 6°C

(10°F) lower than the ambient temperature in which the engine oper-

ates.

-32 to -54°C (-25 to -65°F)

Use 60-percent ethylene glycol antifreeze and 40-percent water for the

engine coolant mixture.

Refer to Lubricating Oil recommendations and Specifications and

Coolant Recommendations and Specifications in the Fuels, Lubricants

and Coolants Section for the correct specifications.

The Diesel fuel must have maximum cloud and pour points 6°C (10°F)

lower than the ambient temperature in which the engine operates.

FUEL SELECTION

In cold weather, the fuel might freeze resulting in difficult engine

starting; therefore, select a suitable fuel for such engine operation.

Use ASTM 975 No. 2-D fuel if you expect the temperature to be above

-7°C (20°F).

Use Number 1-D if you expect temperatures below -7°C (20°F).

If Number 1-D is not available, a "winter" blend of 1-D and 2-D is

available in some areas during the winter months.

Check with your fuel supplier to be sure you get the correct blended

fuel.

COOLANT

Where the ambient temperature falls below freezing point, the cooling

system should be drained after engine operation, but to eliminate the

need for repeated draining, refilling and to provide all year protection

against corrosion, the use of anti-freeze solution throughout the year is

highly recommended.

All Doosan portable compressor engines are factory filled with a 50/50

Ethylene glycol base antifreeze/water mix. which provides protection to

-33°C (-27°F)

Concentrations over about 65% adversely affect freeze protection,

heat transfer rates, and silicate stability which may cause water pump

leakage.

ENGINE OIL

At low ambient temperatures, engine oil viscosity can affect engine

starting. It is important to use the correct grade of oil as recommended.

Try to position the compressor where it will not be affected by cold

winds when not running.

Cold Weather Operating Aids

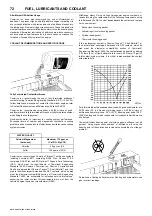

Temperature

Coolant

Heater

Oil

Heater

Under-

hood Air

Battery

Heater

Radiator

Shutters

Engine

Enclosure

Thermatic

Fan

Sug

ge

st

ed

Required Required*

Required

Required

Required

Required

Required

* Required dependent upon viscosity / pour point.

CAUTION: Never exceed a 60/40 antifreeze/water mix. (which pro-

vides protection to about -50°C (-58°F).

NOTE:

Methyl alcohol base antifreeze is not recommended because

of its effect on the non-metallic components of the cooling system

and because of its low boiling point.

NOTE:

High silicate antifreeze is not recommended because of caus-

ing serious silica gelation problems.

NOTE:

Usage and mixing ratio etc. should be followed to the anti-

freeze manufacture's recommendations.