EXHAUST SYSTEM

69

9/275, 9/305, 12/250, 17/240, 21/220

Active regeneration will occur more frequently in equipment with low

load, or stop and go duty cycles.

Active regeneration only occurs if the engine ECM has detected that

the aftertreatment diesel particulate filter restriction has reached a

specified limit. The engine ECM will activate and de-activate

regeneration as needed.

Active regeneration is largely transparent to the equipment operator.

The equipment operator may notice an increase in turbocharger noise

during an active regeneration event, an may notice that the high

exhaust temperature lamp is illuminated, if the exhaust temperature is

greater than the high exhaust system temperature threshold set by the

equipment OEM.

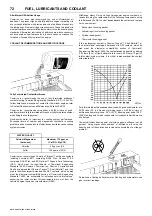

During active regeneration, the exhaust temperature can be hotter than

when the engine is operating at full load. The exhaust temperature

during a normal active regeneration event could reach 600°C (1100°F),

and possibly 800°C (1500°F) under certain conditions.

Manual (Non-Mission)

Under some operating conditions, such as low speed, low load, or stop

and go duty cycles, the engine may not have enough opportunity to

regenerate the aftertreatment diesel particulate filter during normal

operation. When this occurs, the engine will illuminate the

aftertreatment diesel particulate filter lamp to inform the operator that

assistance is required, typically in the form of a Manual (non-mission)

regeneration.

Manual (non-mission) regeneration is a form of active regeneration that

is initiated by the equipment operator when

not

in operation.

Manual (non-mission) regeneration requires an elevated engine speed

of approximately 1000 to 1400 RPM. The length of a manual (non-

mission) regeneration will vary depending on how full the

aftertreatment diesel particulate filter is, but will typically take anywhere

from 45 minutes to 1.5 hours to complete.

A manual (non-mission) regeneration can be initiated one of two ways:

•

An equipment mounted manual (non-mission) regeneration switch.

Use the owners manual for the location and operation of this switch.

The mounted manual (non-mission) regeneration switch will only

initiate a manual (non-mission) regeneration when the aftertreatment

diesel particulate filter lamp is illuminated.

•

The INSITE™ electronic service tool can initiate a manual (non-

mission) regeneration by starting the "Aftertreatment Diesel Particulate

Filter Regeneration Test".

To perform a manual (non-mission) regeneration, follow the steps

listed:

•

Select an appropriate location to park the equipment.

•

Ensure there are no objects directly above the exhaust.

NOTE:

See Section 1 of the Owner's Manual or Operation &

Maintenance Manual of the engine being serviced for additional

information on the engine indicator lamps.

WARNING: During regeneration, exhaust gas temperature could

reach 800°C (1500°F).

WARNING: During regeneration, exhaust gas temperature could

reach 800°C (1500°F), and exhaust system surface temperature

could exceed 700°C (1300°F), which is hot enough to ignite or

melt common materials, and to burn people. Engine speed will

increase and could possibly reach between 1000 to 1500 RPM.

Follow these instructions to avoid the risk of fire, properly

damage, burns, or other serious personal injury.