72

FUEL, LUBRICANTS AND COOLANT

9/275, 9/305, 12/250, 17/240, 21/220

AfterMarket Oil Additive Usage

Cummins Inc. does

not

recommend the use of aftermarket oil

additives. The present high-quality fully additive engine lubricating oils

are very sophisticated, with precise amounts of additives blended into

the lubricating oil to meet stringent requirements. These furnished oils

meet performance characteristics that conform to the lubricant industry

standards. Aftermarket lubricating oil additives are

not

necessary to

enhance engine oil performance and, in some cases, can reduce the

furnished oil's capability to protect the engine.

COOLANT RECOMMENDATIONS AND SPECIFICATIONS

Fully Formulated Coolant/Antifreeze

Cummins Inc. recommends the use of fully formulated antifreeze/

coolant meeting Cummins® Engineering Standard (C.E.S.) 14603. For

further details and discussion of coolant for Cummins® engines, refer

to Coolant Requirements and Maintenance, Bulletin 3666132.

Cummins Inc. recommends using either a 50/50 mixture of good-

quality water and fully formulated antifreeze, or fully formulated coolant

when filling the cooling system.

Good-quality water is important for cooling system performance.

Excessive levels of calcium and magnesium contribute to scaling

problems, and excessive levels of chlorides and sulfates cause cooling

system corrosion.

Cummins Inc. recommends Cummins Filtration™ antifreeze coolants

including Compleat ES™ containing DCA4 Plus, Fleetcool™ EX

containing DCA2 Plus, and ES Optimax™ Organic Acid Technology

(OAT), which meet the requirements of Cummins® Engineering

Standard 14603. However, Cummins Inc., Chevron Corporation and

Shell have agreed that Chevron Texaco™, Shell Rotella™ and their

private label counterpart Extended Life OAT coolants, which do

not

meet the elastomer compatibility section of Cummins® Engineering

Standard 14603, are acceptable for extended service interval use,

assuming the initial coolant fill requirements were met from the

vehicle's original equipment manufacturer (OEM).

MidRange, Heavy Duty and High Horsepower engine overhauls, or

repairs involving the replacement of the following components, using

this Extended Life OAT coolant,

must

discard the coolant and replace

it with new coolant.

•

Rocker lever housing gasket

•

Lubricating oil cooler housing gasket

•

Cylinder head gasket

•

Thermostat housing gasket

If the replacement coolant is Chevron Texaco™, Shell Rotella™ or

their private label counterpart Extended Life OAT coolants, which do

not

meet the elastomer compatibility section of Cummins®

Engineering Standard 14603, the coolant

must

be treated by adding

0.24 liters (8 oz) of liquid silicate fluid for every 45.5 liters (12 gal) of

total coolant system volume. It is critical to

not

overtreat the coolant

with silicate fluid.

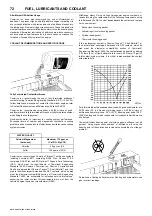

Fully formulated antifreeze

must

be mixed with good quality water at a

50/50 ratio (40- to 60-percent working range). A 50/50 mixture of

antifreeze and water gives a -36°C (-33°F) freezing point and a 108°C

(226°F) boiling point, which is adequate for locations in North America

and Europe.

The actual lowest freezing point of ethylene glycol antifreeze is at 68

percent. Using higher concentrations of antifreeze will raise the

freezing point of the solution and increase the possibility of a silica gel

problem.

Do

not

use a floating ball hydrometer. Floating ball hydrometers can

give incorrect readings.

WATER QUALITY

Calcium Magnesium

(hardness)

Maximum 170 ppm as

(CaCO3 + MgCO3)

Chloride

40 ppm as (CI)

Sulfur

100 ppm as (SO4)