INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

37

In the case of crane series CBE-MBE size V-Z integrate at the point 5

5.1

Insert into the central hole of the upper side pivots’ flange (

5

), the greaser (

10

) and introduce the

grease with the proper equipment.

fig. 52

Note: Check and grease every three months.

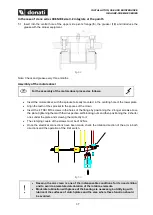

Assembly of the motoreducer

For the assembly of the motoreducer proceed as follows:

•

Insert the motoreducer, with the sprocket already mounted, in the centring hole of the lower plate.

•

Align the teeth of the sprocket to the spaces of the crown.

•

Insert the 4 TCEI M10 screws in the holes of the flange by positioning the 2 longer screws above

the plate, tightening them with their respective self-blocking nuts and then positioning the 2 shorter

ones under the plate and screwing them directly to it.

•

The clamping couple of the screws must be of 32 Nm.

•

Once the electrical connections have been made, check the rotation direction of the arm in both

directions and the operation of the limit switch

.

fig. 53

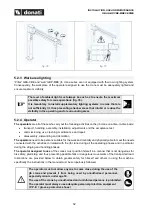

•

Keeping the arm clean is one of the indispensable conditions for its good sliding

and to avoid a premature deterioration of the rotation elements.

•

Moderate lubrication with grease of the bearings is necessary, but dirtying with

lubricant the surfaces of clutch plates and the area where these function should

be avoided.

Содержание CBE Series

Страница 2: ......

Страница 16: ...INSTALLATION USE AND MAINTENANCE GBA GBP CBE MBE SERIES 12 T Version Manual Underbraced version...

Страница 17: ...INSTALLATION USE AND MAINTENANCE GBA GBP CBE MBE SERIES 13 H Version Manual overbraced version...

Страница 19: ...INSTALLATION USE AND MAINTENANCE GBA GBP CBE MBE SERIES 15 H Version Manual overbraced version...

Страница 79: ......