13

CONTAINER DURING THE FIRST CYCLE.

The first few cycles may have small cubes due to air

trapped in the water lines. The first container of ice

cubes should be dumped if the water system has been

winterized or not used for several weeks.

4. HOW TO ADJUST SIZE OF ICE CUBES

If the ice maker has run through several cycles and the

cubes are to small or sticking together, adjustments is

necessary on the amount of water entering the mold. To

adjust the amount of water entering the mold, remove the

protective cover from the ice maker mechanism (See FIG.

13).

To increase the size of the cubes turn the adjusting screw

counterclockwise. To decrease the size of the ice cubes,

turn the adjusting screw clockwise.

CAUTION: DO NOT turn the screw more than one turn at a

time. The ice maker should be allowed to cycle several

times before another adjustment is made. Be sure to replace

protective cover on the cycle after adjustments have been

made.

SECTION E. ICE MAKER OPERATING INSTRUCTIONS

1. WATER CONNECTION

The water supply system must have a minimum pressure of

15 psig and maximum pressure of 100 PSI. A water line 1/

4 inch in diameter shall be used to the water valve connection

at the rear of the refrigerator. The water line must have a

manual shutoff valve placed where it is easily accessible,

and connected to only the cold water supply.

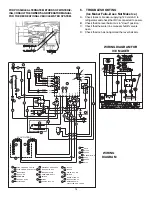

2. 120 VOLT AC ELECTRICAL CONNECTION

The ice maker is equipped with a three-prong (grounded) plug

for protection against shock hazards, and should be plugged

directly into a properly grounded three-prong receptacle. DO

NOT cut or remove the grounding prongfrom this plug. The

free length of the cord is 2 feet and therefore recommended

that the receptacle be located to the right side of the

refrigerator (viewed from the rear) and approximately 6

inches from the floor. This allows easy access through the

vent door. The cord should be routed to avoid direct contact

with the burner cover, flue cover or any other components

that could damage the cord insulation.

3.

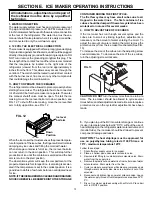

HOW TO OPERATE THE ICE MAKER

The refrigerator must be allowed to precool properly before

starting the ice maker. The refrigerator has to be connected

to 120 volts AC before the ice maker can operate. The water

line manual shutoff valve must be open. To start the ice

making, move the ice level bail arm to down position, see

FIG. 12. To shut off the ice making, move the ice level bail

arm to fully up position, see FIG. 12.

When the ice maker thermostat senses the preset tempera-

ture for ejection of the ice cubes, the fingers will start to rotate

dumping any ice cubes and filling the mold with water.

When storage container is full of ice, the ice level bail arm

can not return to the down position. This will stop further

production of ice until the container is emptied and the bail

arm is return to the start position.

The absorption system will keep the compartment at the

proper temperature for storage of ice. Ice making is acceler-

ated if the temperature is set to the coldest position. It is a

good idea to do this a few hours before an anticipated need

for ice.

NOTE: IF THE ICE MAKER WAS CLEANED AND DRAINED,

NO ICE CUBES WILL BE DUMPED INTO THE STORAGE

All installations, adjustments and repair of

the Ice Maker must be done by a qualified

technician.

Ice level

bail arm

Down

Position

FIG. 12

FIG. 13

5. If you plan to put the RV into winter storage or continue

its use in temperatures below 32°F/0°C without the use of

heat strip/tape (on the refrigerator water solenoid valve and

its outlet tube), the ice maker should be drained to prevent

component damage and leaks.

CAUTION

: The heat strip/tape must be approved for

use on polyethylene tubing rated at 100 PSI max. at

70°F., maximum temperature 125°F.

Follow these steps:

1. Shut off water supply valve to ice maker.

2. Place a shallow pan under water solenoid valve.

3. Remove inlet fitting to ice maker water solenoid valve. Drain

water from the supply line.

4. Remove the plastic nut and water line from outlet side of water

solenoid valve. Drain water from the line.

5. Cycle ice maker several times while blowing compressed air

through water solenoid valve. Be sure all water is out of the

solenoid.

6. Reconnect and tighten lines on water solenoid valve. Leave

the water supply turned off until temperatures are above 32°F/

0°C.

7. Dry out ice maker mold assembly with soft cloth. Place bail

arm in UP/OFF position.