52

999804302 - 02/2018

Repositioning

User Information

Load-bearing tower Staxo 100

Accessory for transporting the winches when

empty:

The

Double wheeled transporter

is bolted into the

connecting sockets on the wheel flange and makes it

easier to wheel the (empty) wheel-units.

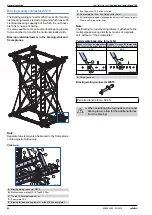

Shifting carriage TG

This is an easy-to-operate, manual hydraulic lifting car-

riage for shifting light to medium-weight tableform units.

As well as making the tableforms easier to move

around, it also makes it easier to erect and strike the

formwork.

▪

Hydraulic, for near-effortless lifting.

▪

Tables can be 'inched' down slowly with handle-con-

trol.

▪

3 guide-rolls, for maximum manoeuvrability.

▪

With an overall width of only 82 cm, the carriage can

pass easily through any doorway when empty.

➤

Push the Shifting carriage TG up against the nar-

rowsides of the tableform – the slot-in lifting profile

reaches under the bottom cross-tube of the frame.

➤

Secure the foot-pieces to prevent them dropping out.

See the section headed 'Lifting by crane'.

Equipment needed for one shifting unit

A

Double wheeled transporter

9716-220-01

A

Max. load per Shifting carriage TG 1000

kg

NOTICE

▪

The floor must be stable, firm and suffi-

ciently smooth (e.g. concrete).

▪

Max. gradient of floor: 5 %.

▪

Max. configuration that can be transported

using 2 Shifting carriages TG: Tables with 3

cross-frames per storey and a max. height

of 5.0

m.

Follow the directions in the 'Shifting carriage

TG' Operating Instructions!

Item

Designation

N° of items

A

Shifting carriage TG

2

A

Shifting carriage TG

B

Slot-in lifting profile

98003-225-01

A

B