14

Auxiliary functions

“Energy saving”

This function manages correct functioning of the cooling fan that

only runs when strictly necessary, that is:

•

FAN MOTOR -

The fan is activated when:

- During welding or for a certain period of time after this is fin-

ished.

- When the thermostat intervenes or for a certain period of time

after it has just been reset.

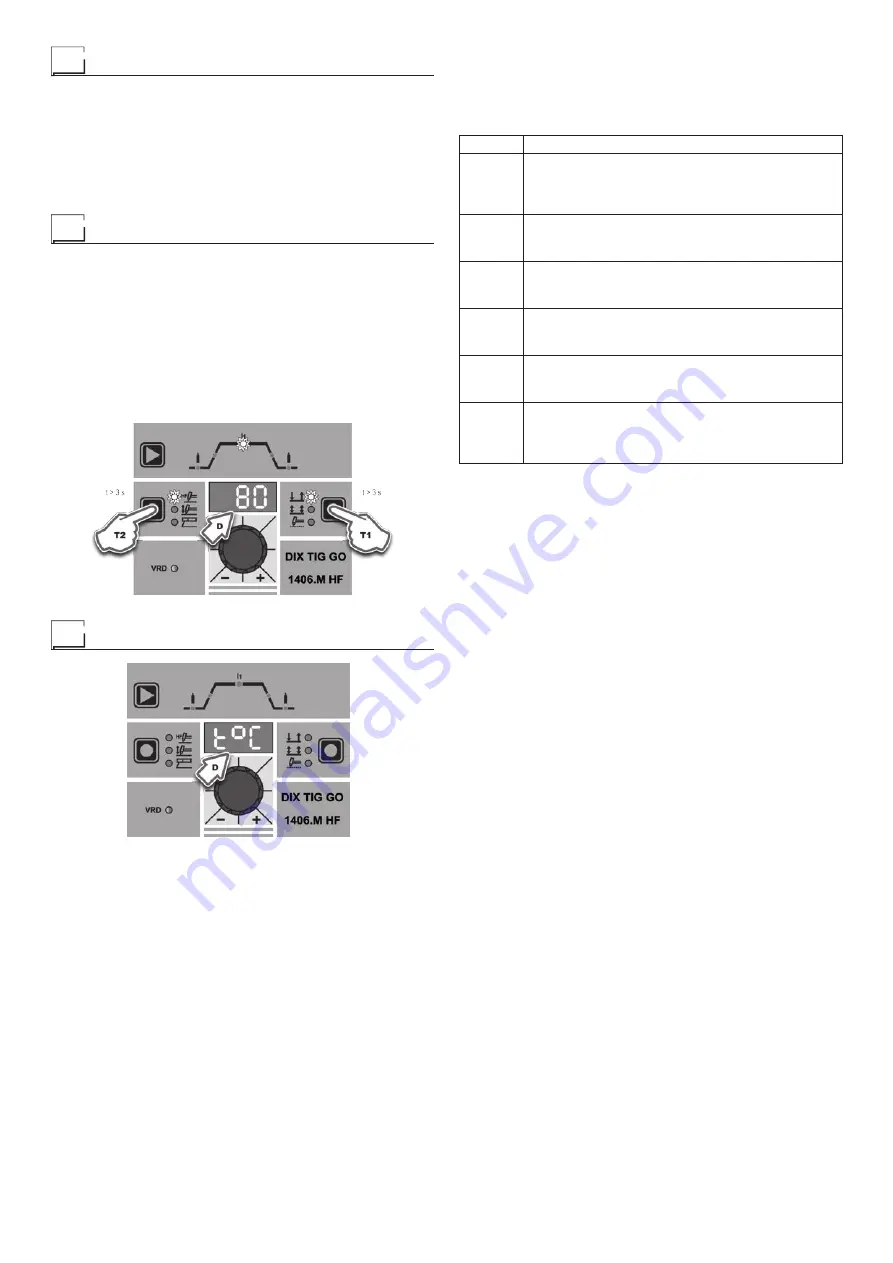

Factory default

WARNING: This operation results in complete resetting of all pa-

rameters to the factory settings.

To reset the settings, you must:

•

With the machine switched on, push and hold down the WELD-

ING MODE (T1) and SELECT WELDING PROCESS (T2) but-

tons simultaneously for about 3 seconds.

•

When all the LEDs switch on at the same time, reinstatement

of the welding machine’s software to its default settings is com-

plete.

•

The message on the DISPLAY (D) reads 80.

•

The reset procedure has now been completed successfully.

Error and protection conditions

The equipment is protected against problems and if any arise the

DISPLAY shows fixed or flashing (error code) messages (depend-

ing on the type of error) that serve to inform the operator that a fault

has occurred in the equipment (see table 1).

The table provides a summary of all the error conditions that may

arise on the equipment and, if possible, what the operator must

do to attempt to resolve the problem.

Automatic reset error:

once the alarm condition has been re-

solved the equipment starts working again and the operator can

weld again!

PLEASE NOTE: If the fault persists look for the cause of the

fault and contact our technical assistance department if nec-

essary.

All of this is necessary to allow our technical assistance depart-

ment to resolve problems more easily, as quickly as possible and

thanks to the user’s reports, also because, in the meantime the

machine will not allow the operator to do their work.

Table 1

Display

Diagnosis

E0.0

POWER SUPPLY FAILURE

NON automatic reset error.

This error can only arise when switching on and not

when the welding plant is working normally.

E1.0

USER FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

E1.1

CONFIGURATION FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

E1.2

INTERNAL MEMORY ERROR

NON automatic reset error.

Immediately contact technical assistance dept.

E1.3

CALIBRATION FILE MISSING

NON automatic reset error.

Immediately contact technical assistance dept.

t°C

THERMAL PROTECTION

The welding stops due to an excessively high

temperature (thermostat activated).

Automatic reset error.

WARNING: The welding machine has a built-in electronic pro-

tective device to deal with fluctuations in mains voltage that

switches the machine off automatically (voltage exceeding

300 V), without indicating any type of error or warning mes-

sage for the operator. Subsequently it starts functioning again

automatically when the voltage has dropped to below the val-

ue indicated above.

Содержание DIX TIG GO 1406.M HF

Страница 9: ...9...