EXITING THE SETUP MENU

1.

Power off the indicator.

2.

Move the slide switch on the rear cover back to the left.

3. Power on the indicator. The display will go through a digit check, then settle into Normal

Operating mode. All front panel keys will now return to their normal mode of operation.

SETUP MENU DESCRIPTIONS

List and detailed descriptions of the items within the setup screens. Factory-set defaults are shown in

bold with a checkmark (

√

).

Note: Most “F” menu items configure the indicator to the attached load cell and are entered by a

qualified instrumentation technician. These parameters do not appear in this manual.

Do not

change these parameters, or the indicator may not function properly or may report highly

inaccurate readings!

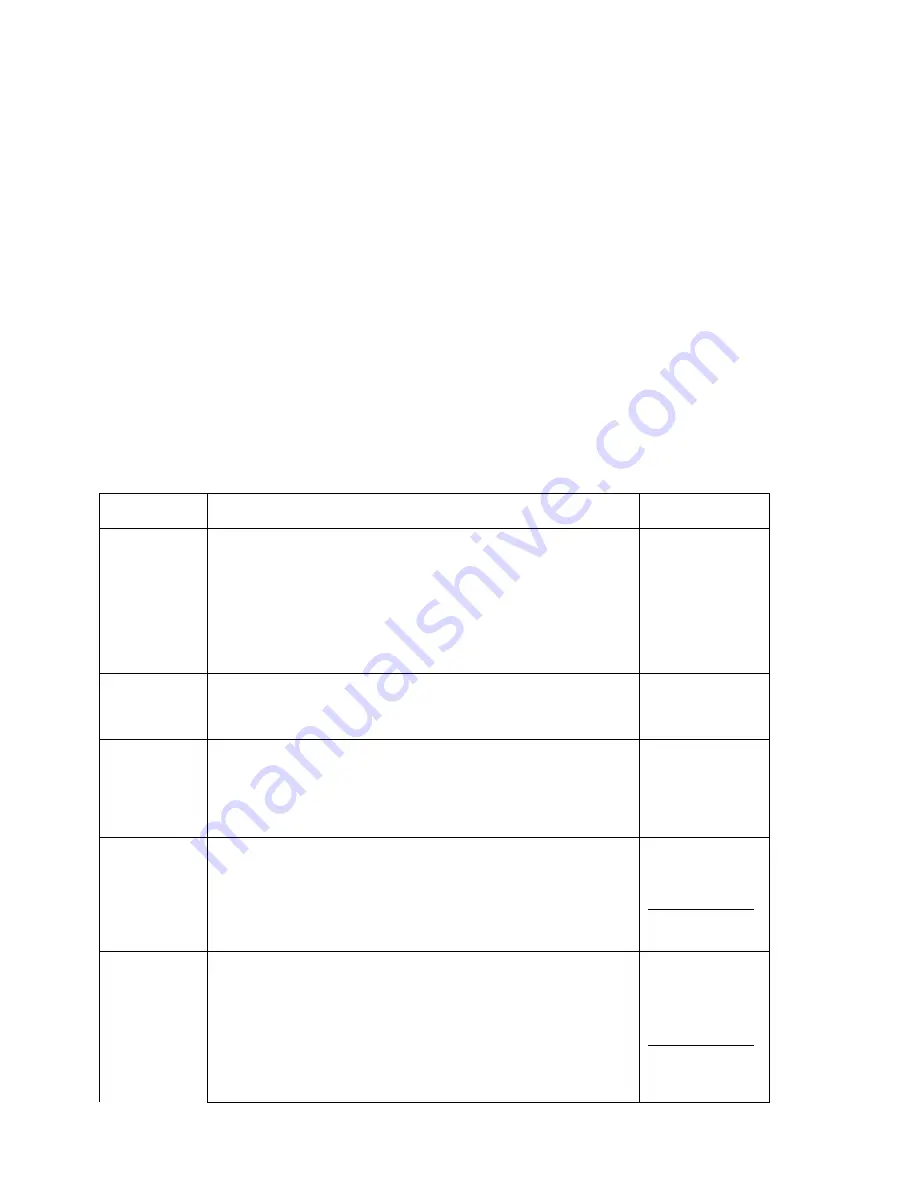

NAME/CODE DESCRIPTION CODE/VALUE

F1

This item is for configuration by a qualified load cell indicator

technician. Do not change this value or the instrument readings may

be in error.

500 1,000

1,500 2,000

2,500 3,000

4,000

5,000

√

6,000 8,000

10,000 12,000

20,000 30,000

40,000 50,000

F2

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument readings may be

in error.

25 50

75

√

100

150 200

F3

This item is for configuration by a qualified load cell indicator

technician. Do not alter this value or the instrument may respond

unpredictably.

0d

0.5d

√

1d

3d

5d

F4

Zero Range

Selects the range within which the scale may be zeroed. Note that the

indicator must be in standstill to zero the scale.

100%

√

1.9%

FI-80 LCD extras:

2%

20%

F5

Motion Band

Defines ‘motion’ in number of divisions of change between the

present display update and the previous display. If motion has been

detected within the prior two seconds, the Print and Zero commands

are disabled.

If a stable reading is not needed for printing or zeroing in your

application, set this value at its highest number.

1d

√

3d

5d

10d

FI-80 LCD extras:

0.25d 15d

20d 30d

40d 50d