Installation

Install the valve between ASME Class 125 or Class 150 pipeline flanges, or other flanges that match

valve end connection. Flange gaskets are required. Before installation, remove foreign material such

as weld spatter, oil, grease, and dirt from the valve and pipeline.

Normal Installations

Install the valve so that the side marked “SEAT” is on the lower pressure side of the valve when the

valve is closed; the pipeline pressure will then help seal the valve in the closed position.

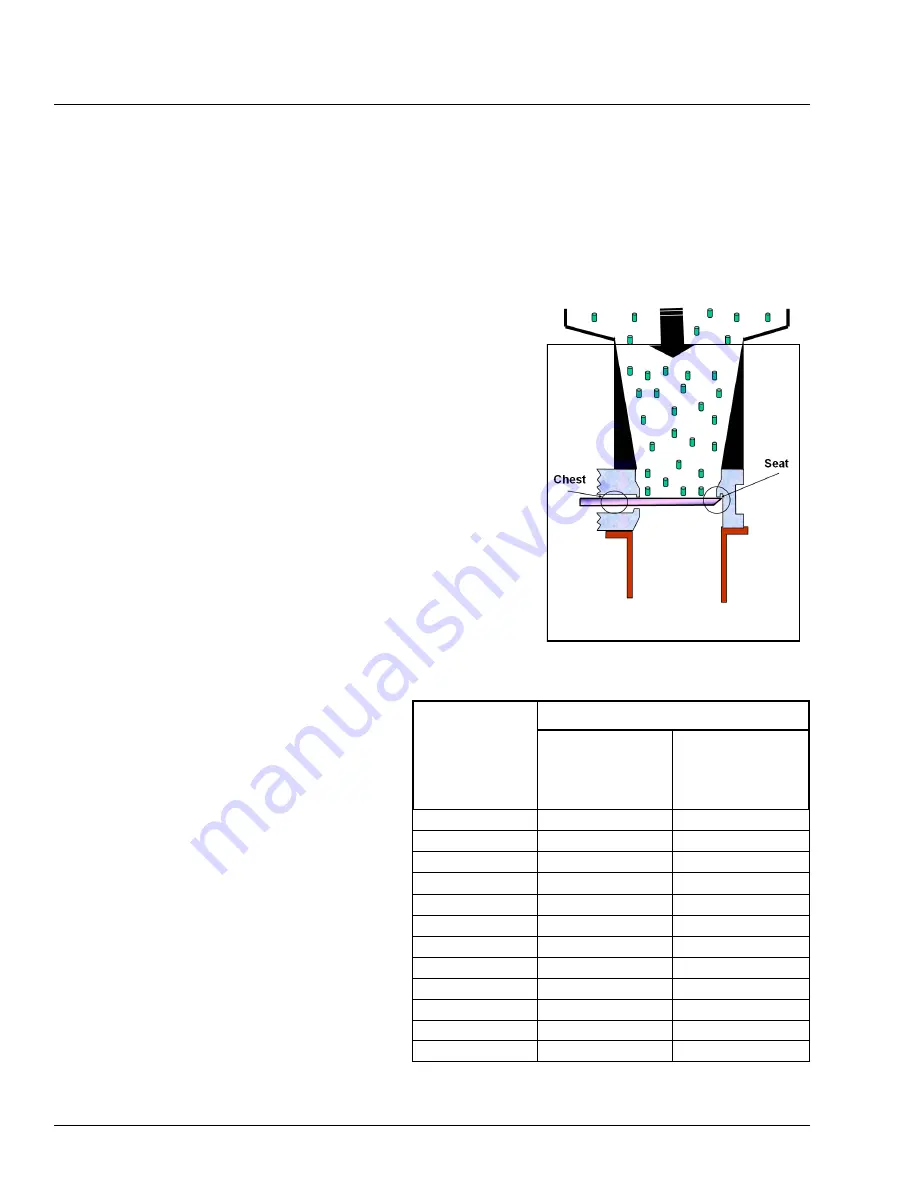

Gravity (Dry) Service Installations

When installing the valve in a vertical pipeline (such as a hopper

bottom, gravity flow, or other dry service application), install the

SEAT side of the valve facing upstream as shown in Figure 1.

Installing the valves with the seat side upstream prevents process

media buildup in the seat and chest area of the valve. This orien-

tation also allows the seat to act as an integral deflection cone,

protecting the seat from wear.

General Guidelines

Observe the following points to prevent distortion of the valve

body and gate when the flange bolts are tightened:

Align the mating pipeline flanges.

Select the length of the flange bolts so that the bolts

used in the blind holes near the chest area of the valve

do not bottom out when tightened.

We recommend using studs with

nuts in the blind holes.

Tighten the flange bolts evenly, in a

crisscross pattern. Refer to Table A

for recommended flange bolt/stud

torques.

Note:

Torque ranges are based on ASME

Pressure Vessel Code Calculations and

lab test data. These torques are only for

the listed gasket types. For other gasket

types listed in ASME, consult DeZURIK.

After installing the valve, pressurize pipeline

and ensure the packing is not leaking. If the

packing leaks, adjust the packing as described

on the next page.

D10411

Page 6

June 2019

DeZURIK

2-24” KGC ES or HD KNIFE GATE VALVES

Valve Size

ASME Gasket Types

Rubber with

Soft Fabric

Filler, & 1/8”

Thick Hard

Soft Elastomer

Gasket Shore

Durometer < 75A

2” (50mm)

26 - 29

8 - 9

3” (80mm)

37 - 41

14 - 16

4” (100mm)

26 - 29

11 - 12

6” (150mm)

41 - 45

22 - 24

8” (200mm)

55 - 61

35 - 39

10” (250mm)

56 - 62

40 - 44

12” (300mm)

80 - 88

59 - 65

14” (350mm)

107 - 118

81 - 89

16” (400mm)

103 - 114

79 - 87

18” (450mm)

128 - 141

102 - 112

20” (500mm)

123 - 136

99 - 109

24” (600mm)

188 - 207

155 - 171

Table A: Recommended Flange Bolt/Stud

Torque Range in ft-lbs (non-lubricated)

Figure 1—Vertical Line/

Hopper Bottom