36

E N G L I S H

• Depress the head to allow the blade to cut through the timber and

enter the plastic kerf plate (32).

• After completing the cut, release the switch and wait for the saw blade

to come to a complete standstill before returning the head to its upper

rest position.

Performing a sliding cut (fig. O)

The guide rail allows cutting larger workpieces from 50 x 100 mm up to

500 x 1000 mm using an out-down-back sliding motion.

• Release the rail lock knob (13).

• Pull the saw head towards you and switch the tool on.

• Lower the saw blade into the workpiece and push the head back to

complete the cut.

• Proceed as descirbed above.

• Do not perform sliding cuts on workpieces smaller than

50 x 100 mm.

• Remember to lock the saw head in the rear position when the

sliding cuts are finished.

Vertical mitre cross-cut (fig. A1, A2 & P)

• Release the mitre lever (4) and depress the mitre latch (5). Move the

arm left or right to the required angle.

• The mitre latch will automatically locate at 10°, 15°, 22.5°, 31.62° and

45° both left and right, and at 50° left and 60° right. If any intermediate

angle is required hold the head firmly and lock by tightening the mitre lever.

• Always ensure that the mitre lever is locked tightly before cutting.

• Proceed as for a vertical straight cross-cut.

When mitring the end of a piece of wood with a small off-cut,

position the wood to ensure that the off-cut is to the side of

the blade with the greater angle to the fence; i.e. left mitre, off-

cut to the right - right mitre, off-cut to the left.

Bevel cuts (fig. A1, A2 & Q)

Bevel angles can be set from 48° left to 2° right and can be cut with the mitre

arm set between zero and a maximum of 45° mitre position right or left.

• Loosen the left side fence clamping knob (30) and slide the upper part

of the left side fence (3) to the left as far as it will go. Loosen the bevel

clamp handle (11) and set the bevel as desired.

• Tighten the bevel clamp handle (11) firmly.

• Proceed as for a vertical straight cross-cut.

Quality of cut

The smoothness of any cut depends on a number of variables, e.g. the

material being cut. When smoothest cuts are desired for moulding and

other precision work, a sharp (60 tooth carbide) blade and a slower, even

cutting rate will produce the desired results.

Ensure that the material does not creep while cutting; clamp it

securely in place. Always let the blade come to a full stop

before raising the arm. If small fibres of wood still split out at

the rear of the workpiece, stick a piece of masking tape on the

wood where the cut will be made. Saw through the tape and

carefully remove tape when finished.

Body and hand position

Proper positioning of your body and hands when operating the mitre saw

will make cutting easier, more accurate and safer.

• Never place your hands near the cutting area.

• Place your hands no closer than 150 mm from the blade.

• Hold the workpiece tightly to the table and the fence when cutting.

Keep your hands in position until the switch has been released and the

blade has completely stopped.

• Always make dry runs (without power) before finish cuts so that you

can check the path of the blade.

• Do not cross your hands.

• Keep both feet firmly on the floor and maintain proper balance.

• As you move the saw arm left and right, follow it and stand slightly to

the side of the saw blade.

• Sight through the guard louvres when following a pencil line.

Cutting picture frames, shadow boxes & other four sided projects

(fig. R1 & R2)

Trim moulding and other frames

Try a few simple projects using scrap wood until you develop a “feel” for

your saw. Your saw is the perfect tool for mitring corners like the one shown

in fig. R1. The joint shown has been made using either bevel adjustment.

- Using bevel adjustment

The bevel for the two boards is adjusted to 45° each, producing a 90° corner.

The mitre arm is locked in the zero position. The wood is positioned with

the broad flat side against the table and the narrow edge against the fence.

- Using mitre adjustment

The same cut can be made by mitring right and left with the broad surface

against the fence.

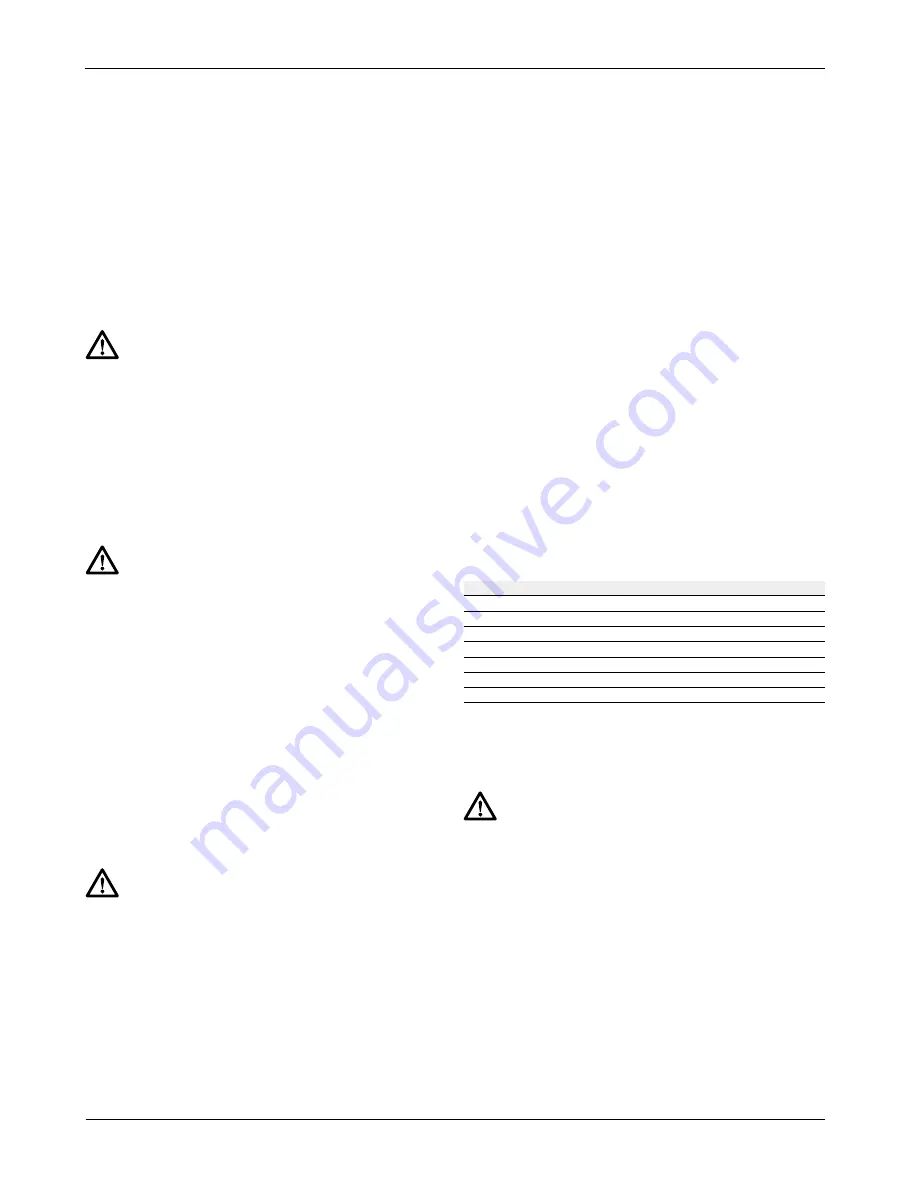

The two sketches (fig. R1 & R2) are for four side objects only. As the

number of sides changes, so do the mitre and bevel angles. The chart

below gives the proper angles for a variety of shapes, assuming that all

sides are of equal length. For a shape that is not shown in the chart, divide

180° by the number of sides to determine the mitre or bevel angle.

No. of sides

Angle mitre or bevel

4

45°

5

36°

6

30°

7

25.7°

8

22.5°

9

20°

10

18°

Compound mitre (fig. S1 & S2)

A compound mitre is a cut made using a mitre angle (fig. R2) and a bevel

angle (fig. R1) at the same time. This is the type of cut used to make

frames or boxes with slanting sides like the one shown in fig. S1.

If the cutting angle varies from cut to cut, check that the bevel

clamp knob and the mitre lock knob are securely tightened.

These knobs must be tightened after making any changes in

bevel or mitre.

• The chart shown below will assist you in selecting the proper bevel and

mitre settings for common compound mitre cuts. To use the chart,

select the desired angle “A” (fig. S2) of your project and locate that

angle on the appropriate arc in the chart. From that point follow the

chart straight down to find the correct bevel angle and straight across

to find the correct mitre angle.

• Set your saw to the prescribed angles and make a few trial cuts.

• Practice fitting the cut pieces together.

• Example: To make a 4 sided box with 25° exterior angles (angle “A”)

(fig. S2), use the upper right arc. Find 25° on the arc scale. Follow the

horizontal intersecting line to either side to get the mitre angle setting

on the saw (23°).

Likewise follow the vertical intersecting line to the top or bottom to get

the bevel angle setting on the saw (40°). Always try cuts on a few scrap

pieces of wood to verify the settings on the saw.

Содержание DW017

Страница 1: ...1 DW017 ...

Страница 3: ...3 A1 7 12 14 11 13 8 9 10 17 18 16 15 22 21 20 1 2 3 4 5 6 ...

Страница 4: ...4 A2 32 26 24 25 23 27 28 29 30 31 ...

Страница 5: ...5 A3 A4 B1 B2 C A5 A6 A7 22 33 34 39 29 39 31 14 13 18 3 31 11 35 36 40 40 40 37 38 ...

Страница 6: ...6 D1 D2 E1 E2 21 22 41 22 41 22 2 17 42 44 45 2 43 ...

Страница 7: ...7 45 43 16 E3 G F2 F3 F4 E5 F1 E4 42 43 45 26 45 46 47 48 49 4 5 50 3 52 47 51 53 53 53 55 54 6 ...

Страница 8: ...8 I1 H I2 I3 I4 I5 I6 J 4 56 57 11 3 52 47 51 28 59 58 10 58 9 58 8 30 3 60 ...

Страница 9: ...9 Q K L M N O P R1 27 61 63 62 64 13 20 1 65 ...

Страница 10: ...10 S1 R2 S2 T U A 15 66 12 67 67 32 67 ...