components (e.g. a condenser) on the network. This

L.E.D. will blink randomly any time a message is received

by the furnace control.

If no blinking is seen within

five minutes, it can be assumed that there is not valid

communications established. Check wiring to make sure

that all points are connected properly.

Further, if this L.E.D. is on continuously, it is an indication

that mis-wiring has occurred.

“STAT” (STATUS) (Red)

L.E.D.

– This L.E.D. blinks twice slowly (¼ second ON, ¾

second OFF) upon power-up.

Pressing the learn button for two seconds will cause the

green “RX” L.E.D. to blink rapidly (for a short period) to

indicate an attempt at communications. If the L.E.D. does

not blink, communications cannot be established.

9.11

MEMORY CARD

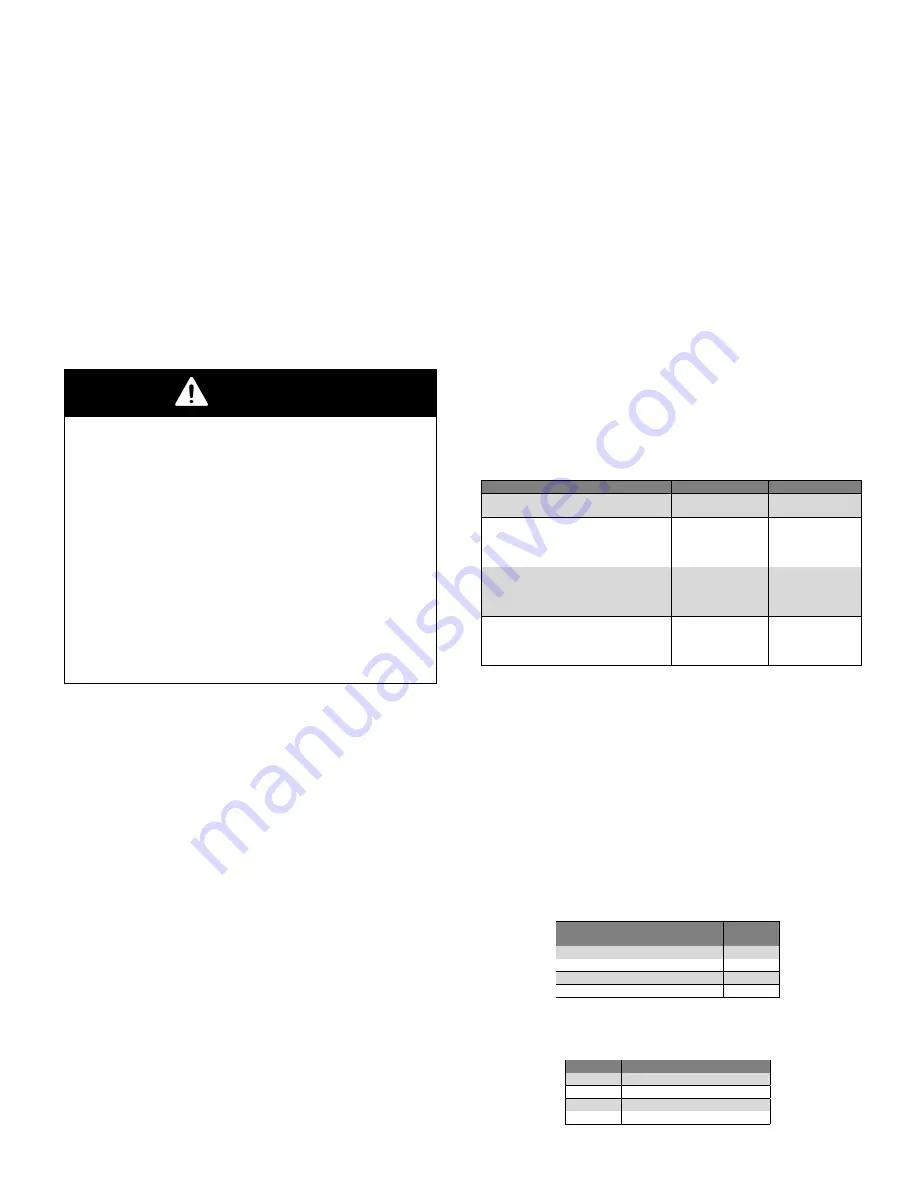

WARNING

Do not replace the furnace control or memory card

of the furnace with a furnace control or memory

card of another furnace or another component

(e.g.

a memory card from a condenser or air

handler). The wrong furnace control or memory

card may specify parameters which will make

the furnace run at undesired conditions including

(but not limited to) reduced airflow during heating

causing excessive undesired operation of the

main limit control.

Further, the memory card

is specific to the model number and BTU input

rating for a specific furnace and this information

should not be transported from one furnace (or

component) to another.

Furnace shared data is defined as data specific to a given

furnace that is critical for proper furnace operation. More

specifically, it is data which defines the operation of the

furnace and is unique to a given furnace platform and

model. The most critical of these data are the coefficients

that control the blower operation (i.e. define the blower

speed-torque operation). Because of this, each furnace

control is programmed with furnace shared data for that

model furnace only. The furnace shared data from any

given furnace can NOT be transferred to another furnace

for any reason. Doing so can adversely affect operation

of the furnace.

Further, if no furnace shared data is

present, the furnace will not operate in any mode and

a fault will be displayed.

9.12

REPLACING FURNACE

CONTROL

In the event that the furnace control must be replaced, the

memory card must be detached from the original furnace

control and retained with the furnace. Failure to save and

connect the memory card properly to the replacement

control may result in no operation or undesired operation

of the furnace.

When replacing the furnace control, be sure to match

the DIP switch settings of the original control on the

replacement.

9.13

DIP SWITCH

The integrated furnace control MAY not recognize switch

setting changes while energized.

DIP switches are ignored on communicating system,

except for test mode. When using the communicating

thermostat R02P032, configuration will be done throught

it. Please refer to the thermostat manual.

9.13.1

CFM Heat adjust

DIP switch bank S1 is used to fine-tune the airflow in

the heating mode.

The switches of bank S1 can be

set to adjust either the minimum heat rate airflow or the

maximum heat rate airflow or both. Also, every firing rate

in between these points will be adjusted accordingly.

NOTE:

All DIP switches on S1 will be shipped in the “OFF”

position. See Table 12.

Table 12 – Heating Airflow Adjustment - S1

S1-1

S1-2

S1-3

S1-4

DESCRIPTION

DEFAULT

OFF

OFF

OFF

OFF

NO

ADJUSTMENT

LOW FIRE

ADJUSTEMENT

(40%)

OFF

ON

OFF

OFF

-7.5%

OFF

ON

OFF

ON

-15%

OFF

ON

OFF

ON

+7.5%

OFF

ON

OFF

ON

+15%

HIGH FIRE

ADJUSTEMENT

(100%)

ON

OFF

OFF

OFF

-7.5%

ON

OFF

OFF

ON

-15%

ON

OFF

ON

OFF

+7.5%

ON

OFF

ON

ON

+15%

BOTH INPUT

ADJUSTEMENT

ON

ON

OFF

OFF

-7.5%

ON

ON

OFF

ON

-15%

ON

ON

ON

OFF

+7.5%

ON

ON

ON

ON

+15%

9.13.2

Cooling airflow select

These DIP switches are used to select the appropriate

cooling airflow based on the amount required. The switch

settings do not affect cooling airflow when installed in

fully communicating system. In that case, the condenser

supplies the information for cooling airflow which is pre-

set at the factory and not adjustable.

See tables 13 and 14 for target CFM and CFM adjust.

Table 13 – Cooling Airflow Adjustement

S3-1

S3-2

CFM

Cooling

capacity

OFF

OFF

600

1.5 T.

ON

OFF

400

1.0 T.

OFF

ON

300

0.75 T.

ON

ON

200

0.5T.

Table 14 – Cooling Airflow % Adjustement

S3-3

S3-4

DESCRIPTION

OFF

OFF

0%

ON

OFF

+10%

OFF

ON

-10%

ON

ON

0%

27

Содержание CC15-M-V

Страница 18: ...Figure 17 Wiring Diagram 18...

Страница 23: ...Figure 25 Direct vent clearance 23...

Страница 24: ...Figure 26 Other than Direct vent clearance 24...

Страница 34: ...12 PART LIST Figure 27 Exploded view...

Страница 35: ...Figure 28 Exploded view continued...

Страница 36: ...Table 19 Part list Chinook Compact...

Страница 37: ...Table 20 Part list continued...

Страница 38: ...13 NOTES 38...

Страница 39: ...39...

Страница 40: ...40...