7

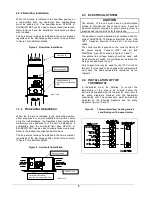

2.6.1 Masonry chimney

This furnace can be vented into an existing masonry chimney.

However, the unit must not be vented into a chimney into

which a solid fuel burning furnace is already being vented.

Before venting this furnace into a chimney, its condition must

be checked and repairs made, if necessary. Also, the chimney

lining and dimensions must conform to local and national

codes.

2.6.2 Factory Built Chimneys

Oil fired furnaces are approved for use with “L” type vents.

The unit may also be used with an approved chimney of

proper dimensions and temperature ratings as specified in the

installation code. Refer to chimney manufacturer’s instructions

for proper installation.

2.6.3 Draft Regulator

It is recommended that a draft regulator be installed in cases

where the draft is either high or variable due to external

conditions. Follow the instructions provided with the regulator.

2.6.4 Side-wall Venting

The heating unit is approved for side-wall venting. This system

includes model VTK-3 / KLAVT0201DET side-wall venter and

a 5” insulated vent pipe, model IFV5 / KLAFVxx01DET. Refer

to the installation instructions provided with the venting

system.

2.7 BLOCKED

VENT

SHUT-OFF

DEVICE

(BVSO)

FOR

CHIMNEY

VENTING

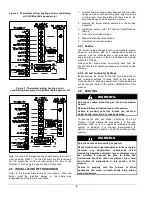

CAUTION

It is imperative that this device be installed by a qualified

service technician.

A positive pressure venting system (Sealed Combustion

System or Direct Vent) MUST NOT use the BVSO. Follow the

instructions supplied with the venting system.

This device is designed to detect the insufficient evacuation of

combustion gases in the event of a vent blockage. In such a

case the thermal switch will shut down the oil burner. The

device will then need to be re-armed MANUALLY.

Refer to the detailed instructions and wiring diagrams supplied

with the BVSO for the installation and wiring procedures. The

length of wires supplied with the unit is such that the safety

device must be installed between the flue outlet of the

appliance and the draft regulator, as indicated in the

instructions.

It is also essential that the BVSO be maintained annually. For

more details refer to the instructions supplied with the device

itself, as well as Section 3. of this Manual.

2.7.1 BVSO Performance Test

The purpose of the following test is to check that the electrical

outlet on the furnace, designated to the BVSO, is functional.

1. Start up the burner;

2. Remove the three-pole plug from the BVSO outlet on the

furnace;

3. The burner must shut-off immediately, while the blower

continues to run to the end of the cool-down cycle.

If the test is not in line with the above, call a QUALIFIED

SERVICE TECHNICIAN.

2.8 COMBUSTION

AIR

SUPPLY

AND

VENTILATION

WARNING

Poisonous carbon monoxide gas hazard.

Comply with NFPA 31 (U.S.) and CSA B139 (Canada)

standards for the installation of Oil Burning

Equipment and applicable provisions of local building

codes to provide combustion and ventilation air.

Failure

to

provide

adequate

combustion

and

ventilation air can result in death, bodily injury and/or

property damage.

Oil furnaces must have an adequate supply of

combustion air. It is common practice to assume that

older homes have sufficient infiltration to accommodate

the combustion air requirement for the furnace. However,

home improvements such as new windows, doors, and

weather stripping have drastically reduced the volume of

air infiltration into the home.

Refer to oil furnace installation codes relative to

combustion and ventilation air requirements. Consult

Section 2.2 in this manual, specifically for units installed

in an enclosed space.

Home air exhausters are common. Bathroom and kitchen

fans, power vented clothes dryers and water heaters all

tend to create a negative pressure condition in the home.

Should this occur the chimney becomes less and less

effective and can easily downdraft. In certain cases,

mechanically supplied air, by way of a blower, interlocked

with the unit, is necessary. It is the installer’s

responsibility to check that.

2.8.1

Contaminated Combustion Air

Installations in certain areas or types of structures will

increase the exposure to chemicals or halogens that may

harm the furnace. These conditions will require that only

outside air be used for combustion.

The following areas or types of structures may contain or

be exposed to certain substances, potentially requiring

outside air for combustion:

a. Commercial buildings;

b. Buildings with indoor pools;

c.

Furnaces installed near chemical storage areas.

Exposure to the following substances:

a. Permanent wave chemicals for hair;

b. Chlorinated waxes and cleaners;

c.

Chlorine based swimming pool chemicals;

d. Water softening chemicals;

e. De-icing salts or chemicals;

f.

Carbon Tetrachloride;

g. Halogen type refrigerants;

h. Cleaning solvents (such as perchloroethylene);

i.

Printing inks, paint removers, varnishes, etc. ;

j.

Hydrochloric acid;

k.

Solvent based glue;

l.

Antistatic fabric softeners for clothes dryers;

m. Acid based masonry cleaning materials.

Содержание AMP154SD

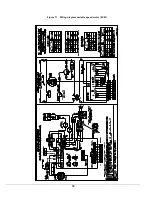

Страница 17: ...17 Figure 9 Furnace Dimensions ...

Страница 18: ...18 Figure 10 Wiring diagram 4 speed motor PSC ...

Страница 19: ...19 Figure 11 Wiring diagram variable speed motor ECM ...

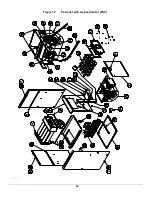

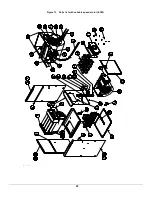

Страница 20: ...20 Figure 12 Parts list with 4 speed motor PSC B500111A ...

Страница 22: ...22 Figure 13 Parts list with variable speed motor ECM B50112A ...