10

3

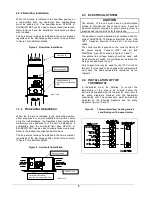

OPERATION

3.1 START-UP

Before starting up the unit, be sure to check that the following

items are in compliance:

1.

The electrical installation, the oil supply system, the

venting system, combustion air supply and ventilation;

2.

The blower access door is in place and the blower rail

locking screws are well tightened;

3.

The Blocked Vent Shut-Off (BVSO) is installed according

to instructions (for chimney venting);

4.

The oil supply valve is open;

5.

The burner ‘’Reset’’ button is well pushed in or re-armed;

6.

The preliminary air adjustments on the burner comply

with the technical specifications in this manual;

7.

The blower speed adjustments for heating and air

conditioning are appropriate and according to the

specifications in this manual;

8.

The blower start/stop delays are satisfactory;

9.

The thermostat of the room is in the heating mode and is

set higher than the ambient temperature.

To start the unit, turn the main electrical switch on.

3.2

OPERATING

SEQUENCE

OIL

HEATING

MODE

1.

The W-R contact closes;

2.

The burner motor starts up to pre-purge the combustion

chamber for a period of 10 to 15 seconds. During that

time a spark is established on the electrodes;

3.

The solenoid valve opens and a flame is established.

Shortly after, the electrodes cease to spark;

4.

Then the blower runs up to full speed. The delay depends

on the adjustments that were made on the electronic

board, which controls the blower motor. Refer to Sections

2.11 and 2.12 above as well as the airflow tables for more

details.

5.

When the call for heat is satisfied, the solenoid valve

closes, the flame goes out and the burner motor stops

(after post purge delay, if applicable).

6.

The blower stops shortly after the burner. The delay

depends on the adjustments that were made on the

electronic board that controls the blower. Refer to

Sections 2.11 and 2.12 above as well as the airflow table

for more details.

Note: A detailed operating sequence of the oil burner is

outlined in the instructions provided with the burner.

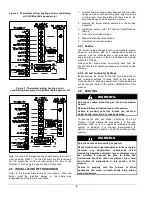

3.3

CHECKS

AND

ADJUSTMENTS

3.3.1

Purging the oil line

Open the bleed port screw and start the burner. Allow the oil

to drain into a container for at least 10 seconds. The oil should

flow absolutely free of white streaks or air bubbles to indicate

that no air is being drawn into the suction side of the oil piping

and pump. Slowly close and tighten the bleed screw. Once

closed, the flame will light up.

3.3.2

Pressure adjustment

The oil pressure must be adjusted according to the

Technical Specifications of this manual. An adjustment

screw and a connection for a pressure gauge are located

on the oil pump for that purpose. Also refer to the burner

instruction manual.

3.3.3

Combustion Check

IMPORTANT

The heat exchanger metal surfaces may have oil and the

baffle insulation also contains binders. These products

will burn or evaporate when the unit operates for the first

time. Because of this, the smoke reading may be inexact

during the first minutes of operation. Therefore, the unit

must operate during at least 60 minutes before taking any

readings to adjust the combustion quality. Let the unit

cool down before making any adjustments.

IMPORTANT

The combustion check verification MUST be performed

after the nozzle replacement or the burner cleaning. After

these manipulations, the combustion parameters are

necessarily modified. Refer also to the burner instruction

manual.

1.

Drill a test hole in the flue pipe, approximately 18

inches from the furnace breech. Insert the smoke test

probe into the hole. For installation using a sidewall

venting, use the orifice provided on the breech plate;

2.

From a cold start, let the unit operate for about 5

minutes;

3.

Set the burner air setting until you have between 0

and 1 on the Bacharach Scale (or a “trace”);

4.

Take a CO

2

sample at the same test location where

the #1 smoke reading was taken and make note of it.

Example: 13.8% of CO

2

or 2.5% of O

2

;

5.

Adjust the burner air setting to obtain a CO

2

reading

1.5% lower (or a O

2

reading 2.0% higher) than the

reading associated with the “trace” of smoke.

Example: 12.3% of CO

2

or 4.5% of O

2

;

6.

This method of adjusting the burner will result in

clean combustion (Bacharach smoke scale between

0 and a trace) and ensure the proper functioning of

the system. The optimum CO

2

level is around 12% to

13% (or 3.5% to 5.0% of O

2

).

3.3.4

Draft Regulator adjustment

On chimney installations only, a barometric draft regulator

(supplied with the furnace) must be installed, in order to

ensure proper draft through the furnace. The barometric

damper must be mounted with the hinge pins in a

horizontal position and the face of the damper vertical for

proper functioning (see instructions included with the

damper.) After the furnace has been firing for at least five

minutes, the draft regulator should be set to between -

0.025" and -0.060" W.C.

Содержание AMP154SD

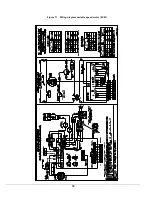

Страница 17: ...17 Figure 9 Furnace Dimensions ...

Страница 18: ...18 Figure 10 Wiring diagram 4 speed motor PSC ...

Страница 19: ...19 Figure 11 Wiring diagram variable speed motor ECM ...

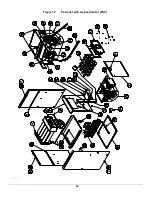

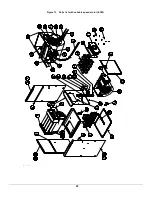

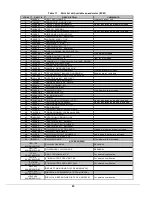

Страница 20: ...20 Figure 12 Parts list with 4 speed motor PSC B500111A ...

Страница 22: ...22 Figure 13 Parts list with variable speed motor ECM B50112A ...