- 31 -

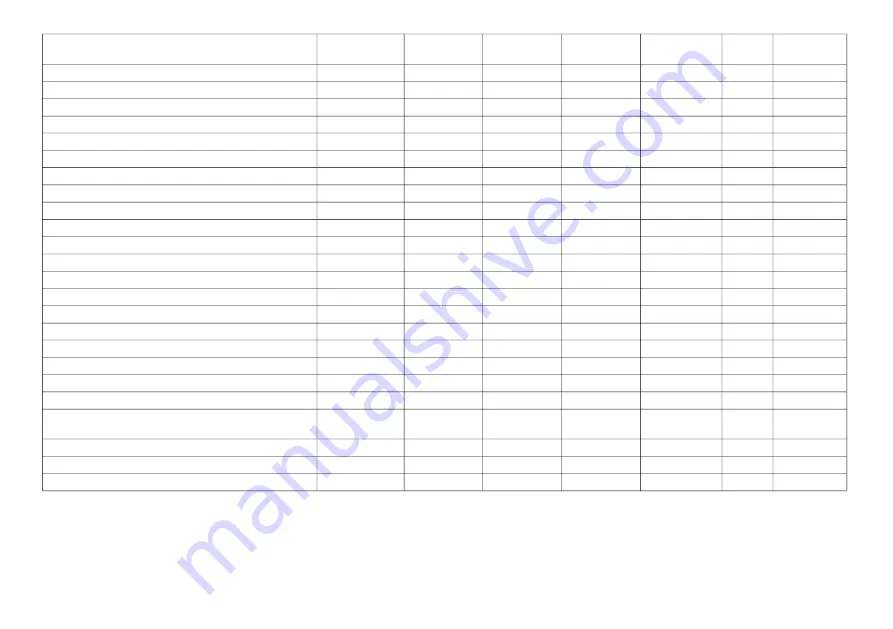

Clean oil cooler(s)/radiator

x

x

Inspection by Denyo service technician

x

x

Check engine & compressor anti-vibration pads

x

x

Check functioning of regulating valve

x

x

Check electrical system cables for wear

x

x

Check engine (minimum and maximum) speed

x

x

Clean flow restrictor in oil scavenge line

x

x

Grease hinges

x

x

Check/Test glow plugs-grid heater

x

x

Replace bleed-off valve unloader

x

x

Check rubber flexibles

(9)

x

x

Analyse coolant

(3)(7)

x

x

Replace fan belt

x

Adjust engine inlet and outlet valves

(2)

x

Replace oil separator element

x

x

Check/Replace safety cartridge

x

x

x

Replace compressor oil filter(s)

(4)

x

x

x

Change compressor oil

(1)(6)

x

x

Replace air filter element

(1)

x

x

x

Measure alternator insulation resistance

(on optional genset)

x

Check electrolyte level and teminals of battery

x

Test safety valve

(8)

x

Check emergency stop

x

Maintenance schedule (running hours)

50 hours after

intial start-up

Every 250

hours

Every 500

hours

Every 1000

hours

Every 1500

hours

Yearly

Biennially

Service parts

-

3002 6085 20 3002 6085 30 3002 6085 40 3002 6085 50

-

-

(continuation of page 30)

Содержание DU-190

Страница 1: ...8 Instruction Manual English...

Страница 2: ......

Страница 16: ...16 Main Parts...

Страница 18: ...18 COMPRESSOR REGULATING SYSTEM...

Страница 22: ...22 CONTINUOUS PNEUMATIC REGULATING SYSTEM...

Страница 60: ...60 ELECTRIC SYSTEM Circuit diagram 9829 3801 10...

Страница 61: ...61 Circuit diagram 9829 3801 10...

Страница 62: ...62 ELECTRIC SYSTEM Wire harness 1094 3133 02...

Страница 65: ...65 Maintenance Log Compressor Customer Serial number Service hours Maintenance action Date By initials...

Страница 67: ......

Страница 68: ......