RD20026

Page 25

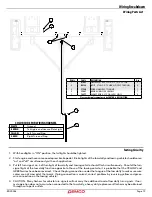

1. Place the main frame (#29) on blocks or some other sturdy support so that the

frame rests approximately 8” - 10” off the ground.

2. With an assistant, place tongue assembly (#26) into main frame channel and

position latch on tongue approximately 3” from front of channel. Clamp tongue

to main frame and support front of tongue.

3. Locate the four bullet connectors extending out the back of the tongue and

plug into the connector protruding from under the main frame channel. Plug

into the flat four connector by matching the colors. Do not cross colors when

making this connection.

4. Using the open end of a 9/16” wrench to support the back of the male coupler,

(as shown below) push drip free quick couplers together.

NOTE:

When pushing

the male connector into the female connector, the female knurl collar will snap

towards male connector automatically, locking the connection.

5. With an assistant, mount the tongue assembly (#26) to the front of the tow

dolly main frame and use a 5/8” x 4-1/2” grade 5 bolt (#13) and lock nut

(#15) (torque to 50 ft. lbs). Do not torque over 50 ft. lbs. or bed will not tilt.

NOTE: Brake line and wiring must be above bolt also coupler assembly must

be ahead of bolt.

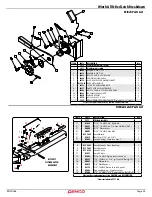

6. Lay the bracing struts (#17) out along the tow dolly tongue with the back end

(the end with the larger hole in it) of the bracing strut toward the main frame.

Loosely bolt the back of each bracing strut to the trailer frame as shown using

1/2” x 1-1/2” grade 5 bolt (#8), flatwasher (#2), pivot bushing (#14) and locknut

(#10). Hold up the front end (the end with the smaller hole) of each bracing

strut to the tongue and secure with two 5/8” x 1-1/4” epoxied hex head bolts

(#18) and nut plate (#25). Torque the 1/2” x 1-1/2” bolt with the pivot bushing

to 75 ft. lbs. Torque the two 5/8” x 1-1/4” epoxied hex head bolts to 100 ft. lbs.

7. With the top platform (#27) off from undercarriage (#29) and the back wear

plate screw (#24) removed, attach the tilt bed ramps (#28) as shown using two

7/16” x 1” grade 8 bolts (#19) and lock nuts (#20) on top of each ramp, and

four, two on each side of the ramp of 1/2” x 1-1/4” bolts (#7) and 1/2” nylon

lock nuts (#10). Reinstall back wear plate screw (#24).

8. Install top platform (#27) onto Undercarriage (#29) and fasten using the 3/4” x

5-1/2” bolt (#22), 3/4” flat washer (#5) and 3/4” lock nut (#4).

Torque to 100 ft. lbs

9. Remove the 7/16” x 1-1/4” bolt (#9), flatwasher (#1), and locknut (#11) from the

outer front panel of each wheel platform tire stop. Slide the tie-down winch

(#30) into the channel at the front of the wheel platforms as shown.

The ratchet

handles are to the outside of each winch and ratchet springs are to the top.

Reinstall

fasteners and torque to 50 ft. lbs.

10. Install fenders (#31) on tow dolly by installing fender backing plate (#21) and

three 3/8 x 1-1/2” bolts (#6). and put nylon lock nuts (#16) on inside of fender

and torque to 30 ft. lbs.

11. Fish the three wires from the mainframe through the rear hole in the fender.

12. Route wiring in through back of tail light housing on the bottom inside of

housing. Fish the three wire inside of housing.

13. Pull all wire from light hole in housing and install the snapper hose clip ap-

proximately 1-1/2” back from end of wire shielding. Squeeze snapper clip

tight with pliers. This is to prevent wires from being pulled out of light hous-

ing.

14. Push wires back into housing and finish routing wires in wire trough of fender

and attach cable hanger. Install two metal wire clips using pliers. Place one

clip 5-1/2” from rear of fender and one 8” from rear of fender.

15. Install rubber grommet, plug in wiring to light and attach 3 wire pigtail har-

ness to fender wiring. NOTE: On the left side, plug in the bullet plugs with

white to white, black to brown, and yellow to red. On the right side, plug in

the bullet plugs with white to white, black to brown, and green to red.

16. Install light into grommet, making sure light is fully seated in grommet.

17. Attach the tire/rim assembly (#23) to the mainframe (#29). Use the supplied

lug nuts (#12) and torque to 120 ft lbs.

Female Coupler

Male Coupler

9/16 Wrench

Boxed Tow Dolly Assembly Instructions

Assembly Instructions

Содержание Kar Kaddy X

Страница 1: ...RD20026 Rev 6 08 20 TOW DOLLY Kar Kaddy X...

Страница 28: ......